3E FLEX Dosing Cell

The configurable entry-level model for standard applications with 2K polyurethane or silicone systems for foam gasketing, bonding and potting

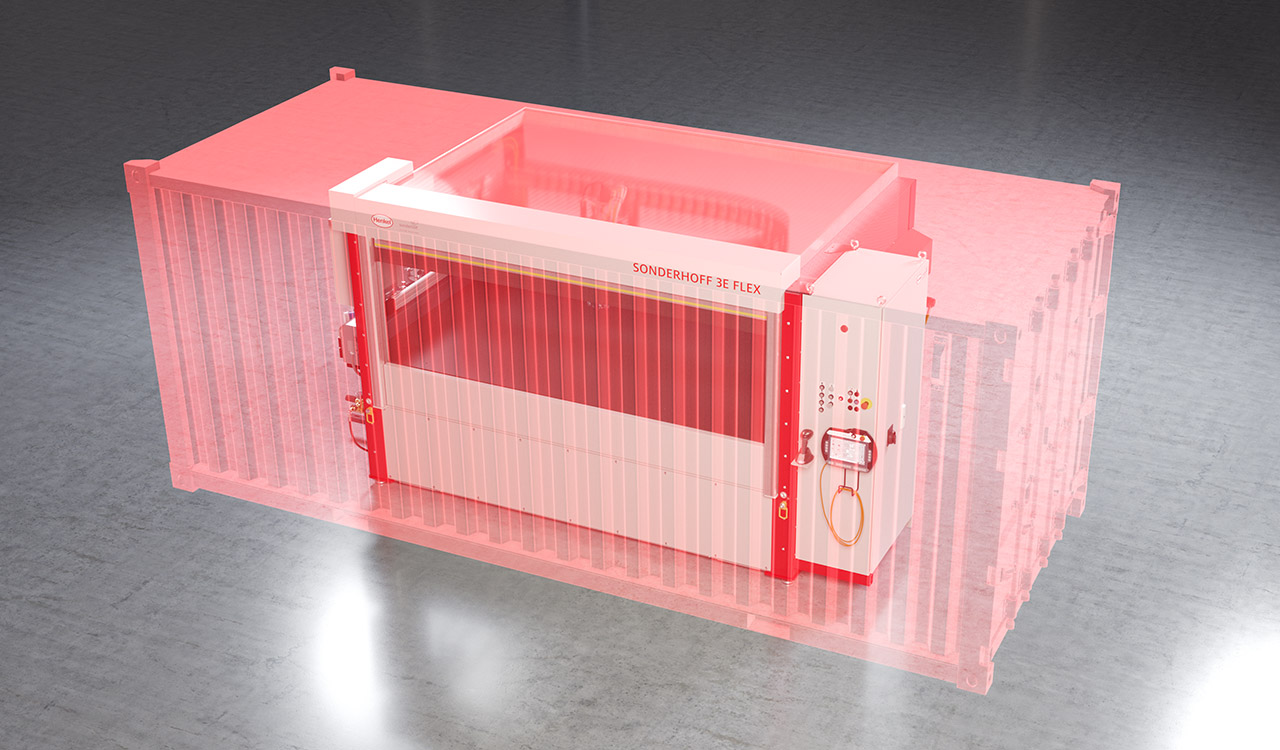

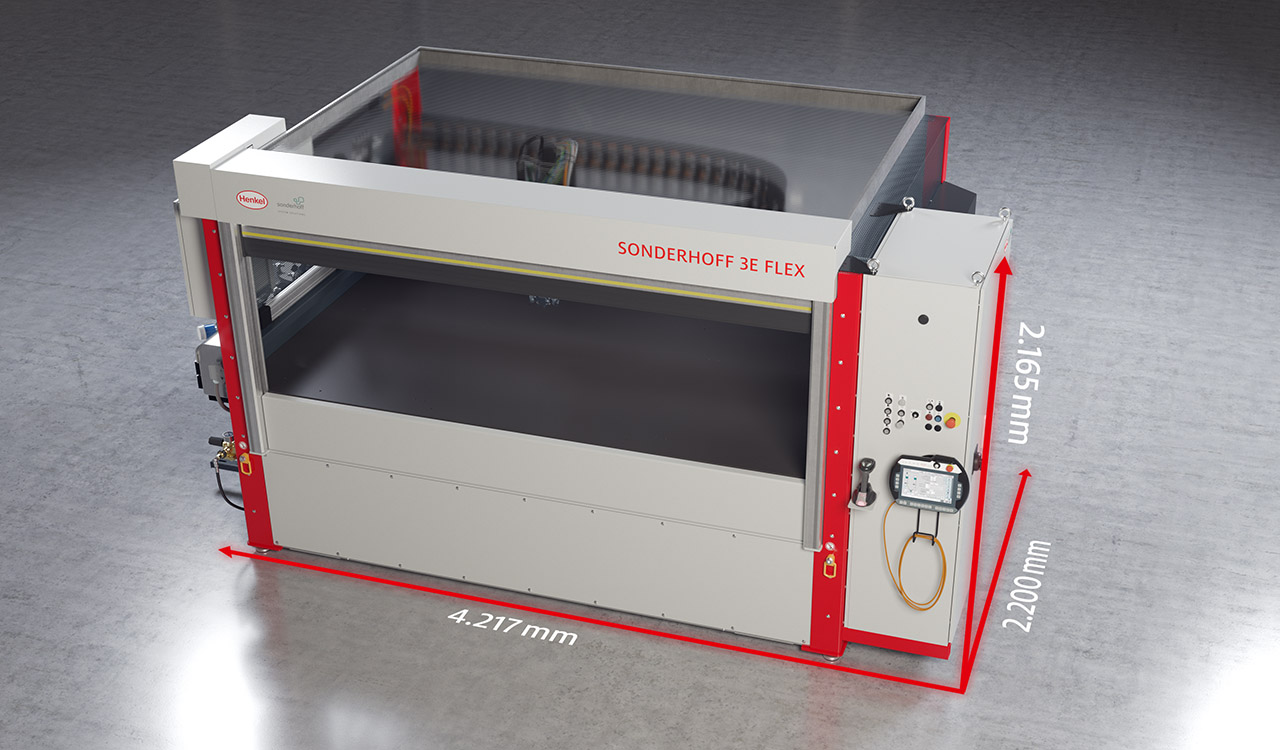

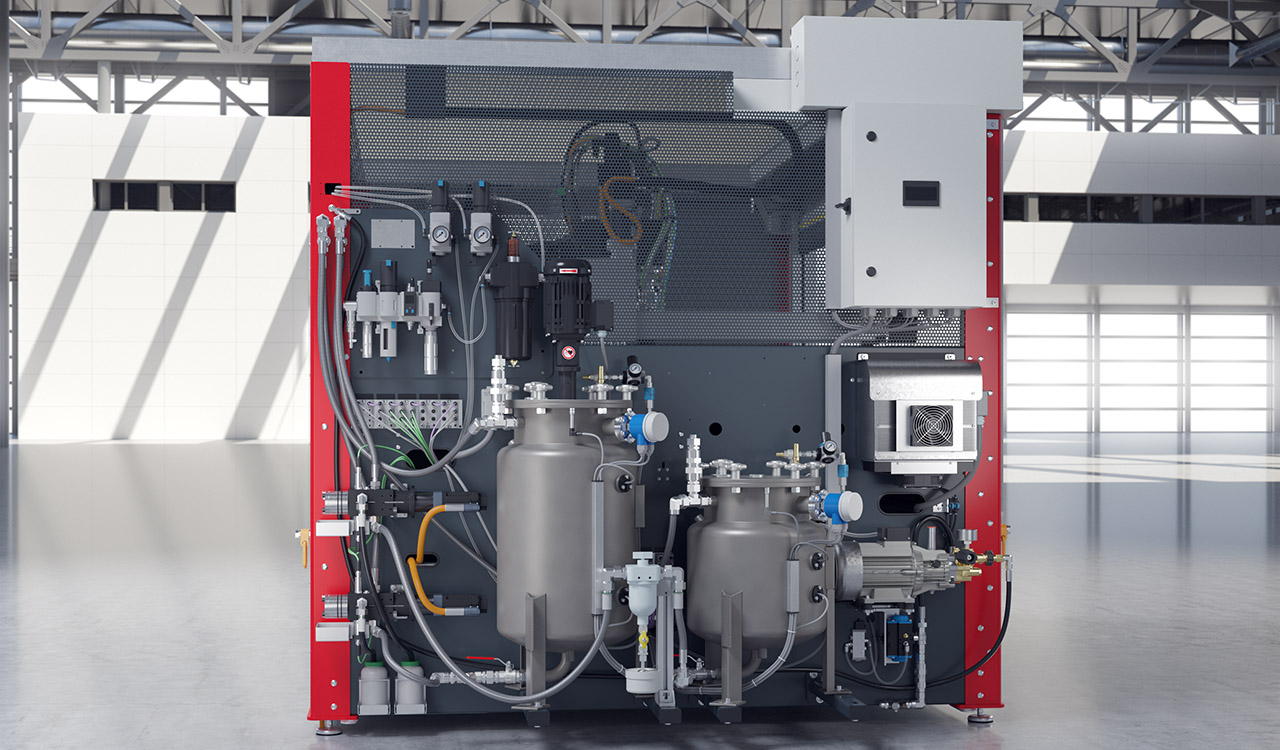

The SONDERHOFF 3E FLEX can be flexibly configured according to your different manufacturing needs. You can choose whether you want to use the 3E FLEX to process and dispense polyurethane- or silicone-based 2K material systems with asymmetrical or symmetrical mixing ratios. All system components are installed on one chassis, which considerably simplifies transport and commissioning: set up, connect and produce – place, plug & work!

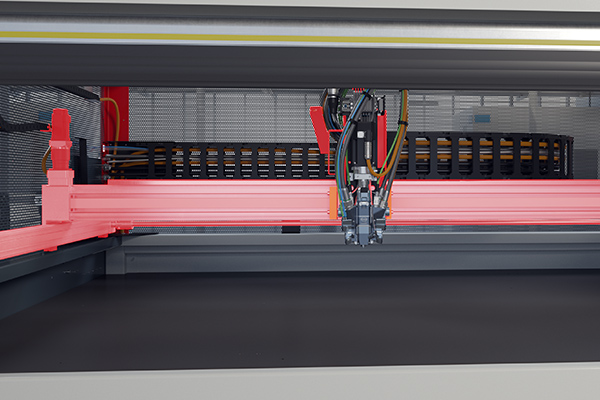

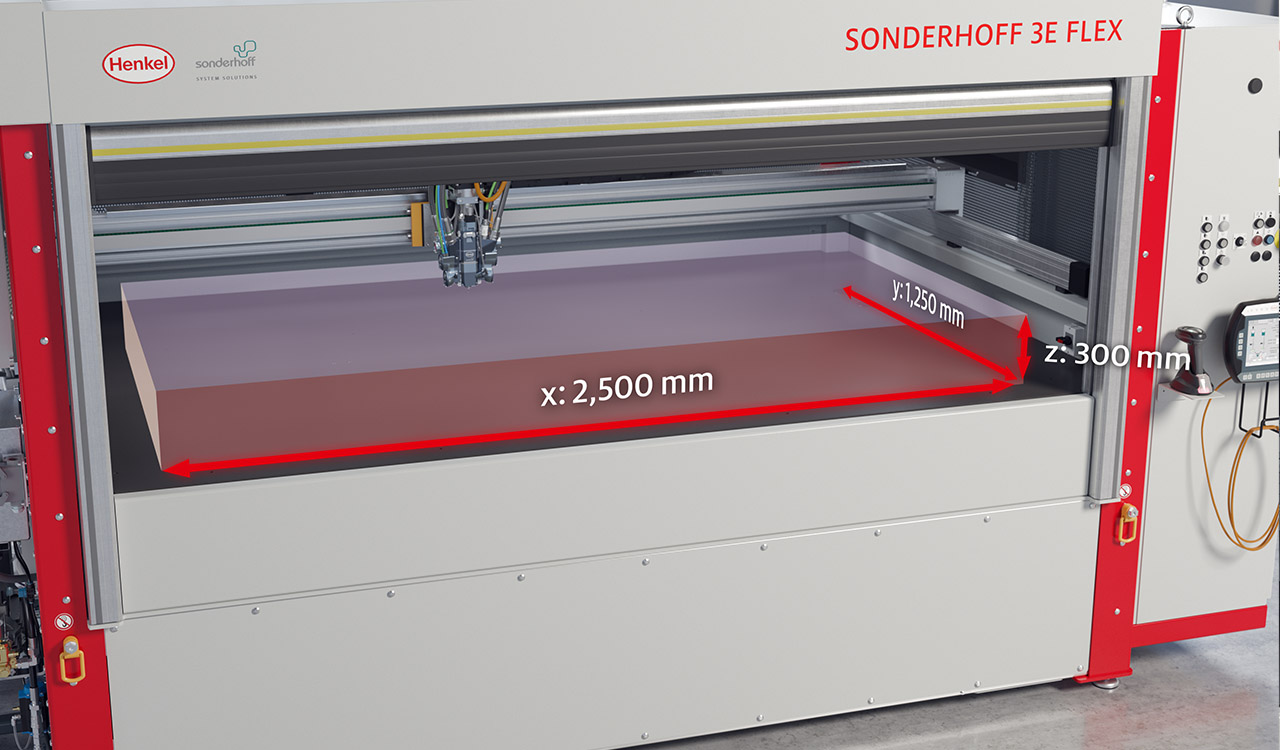

The dynamic high-performance mixing heads MK 800 PLUS or MK 825 PLUS available for the 3E FLEX are guided by the linear robot of the dosing cell in a maximum traversing range of 2,500 x 1,250 x 300 mm (x/y/z). The 2K material system used is mixed dynamically and homogeneously in the mixing head and precisely dispensed in the defined mixing ratio – a prerequisite for high quality.

If desired, the optionally available hand scanner can be used to select the dispensing and CNC program for the part to be processed. The CNC-controlled mixing head then ensures repeat-accurate and fully automatic Formed-In-Place (FIP) material application to the part.

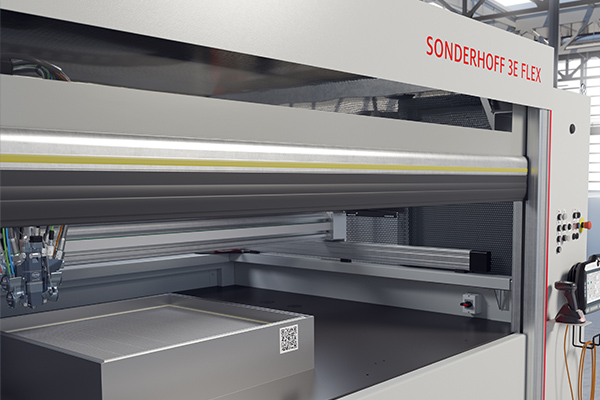

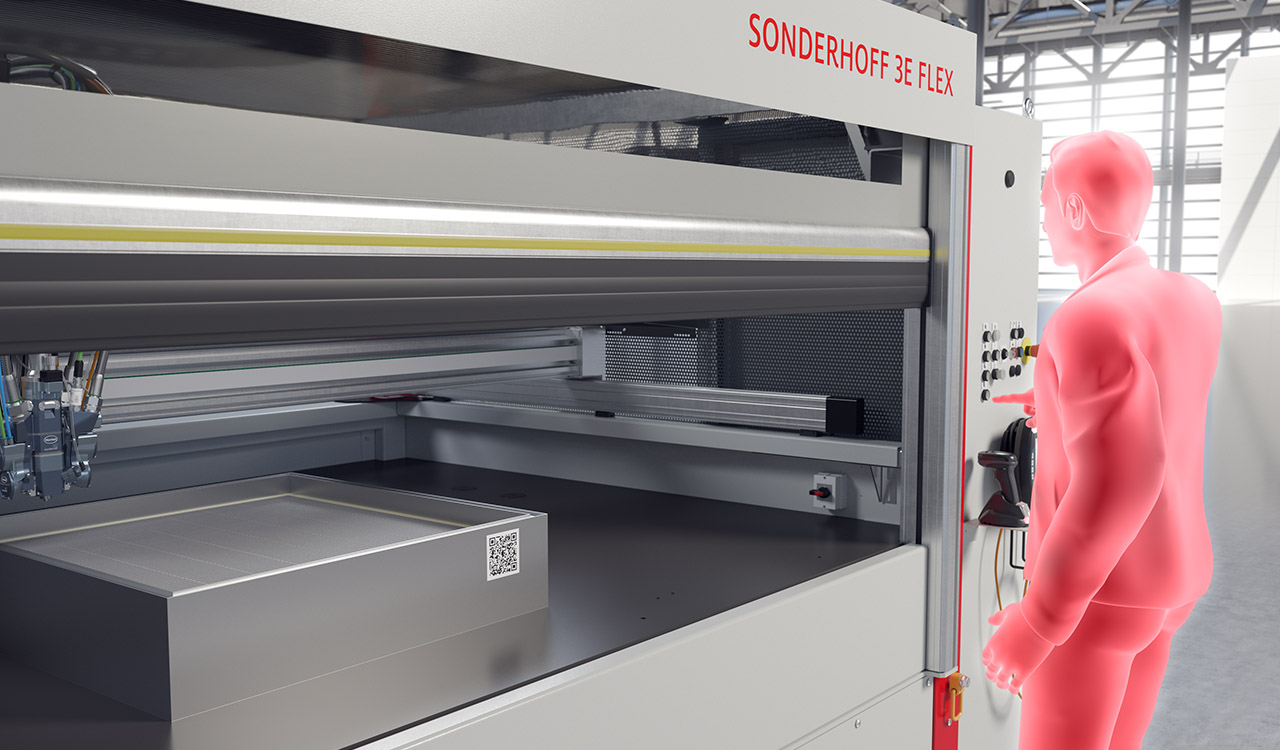

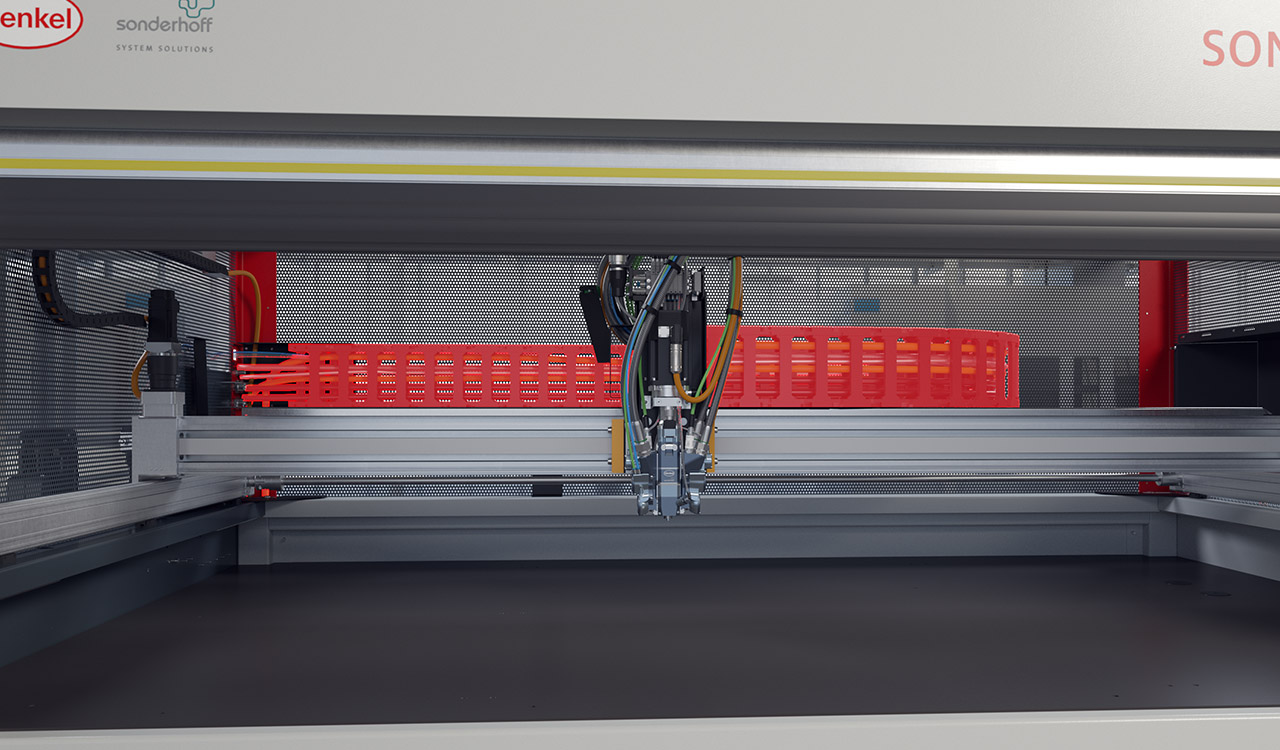

The machine operator is separated from the working area by an automatic high-speed door which makes the dosing cell CE-compliant.

The material pressure tanks on the chassis of the dosing cell are available in two sizes and can be flexibly combined, either both tanks with 24 or 44 liters each or as a combination with 24 and 44 liters. For a continuous material supply, automatic refilling stations for drums or containers are optionally available.

The components are positioned either manually in the work area of the dosing cell or on the optional sliding/shuttle table. For oversized components, the two sliding tables can be connected to form a large work table.

Another advantage for more flexibility is the variable table height in the dosing cell, allowing component heights from 300 to 600 mm. The standard work/table height is 1,000 mm and can be reduced to 700 mm, for example, to integrate manufacturing automation. If required, a transfer belt running through the cell can be installed for clocking in and out the components.

The new video of the SONDERHOFF 3E FLEX Dosing Cell

Here you will learn how easy it is to commission and operate the

3E FLEX dosing cell – place, plug & work!

The video also informs you about the functionality of the dosing cell, how you can configure the individual machine components, where they are located on the system and how the optional shuttle table can be attached to the dosing cell.

3E FLEX Dosing Cell at a glance

Configurable mixing and dosing machine in cellular design for the processing and dispensing of

2K polyurethane or silicone systems

Dosing components and material tanks

MP 2 mobile panel

Linear Robot

Optional refilling station

Control cabinet

Mixing head MK 825 PLUS

Hand scanner

Optional shuttle table

Automatisches SchnelllauftorAutomatic high speed door

Dosing components and material tanks

MP 2 mobile panel

Linear Robot

Optional refilling station

Control cabinet

Mixing head MK 825 PLUS

Hand scanner

Optional shuttle table

Automatisches SchnelllauftorAutomatic high speed door

Dosing components and material tanks

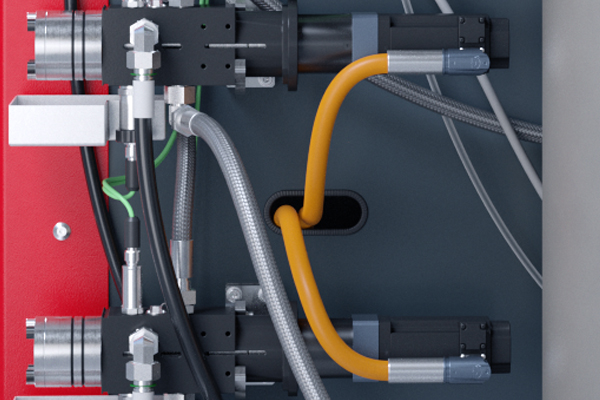

On the front side on the left, for example, there are precision gear pumps, the high-pressure water rinsing unit for mixing head flushing, and the material pressure tanks for the A and B components.

MP 2 mobile panel

The multifunctional MP 2 Mobile Panel (10.1" WXGA TFT) enables convenient operation of the dosing system.

More information to our operating panelsLinear Robot

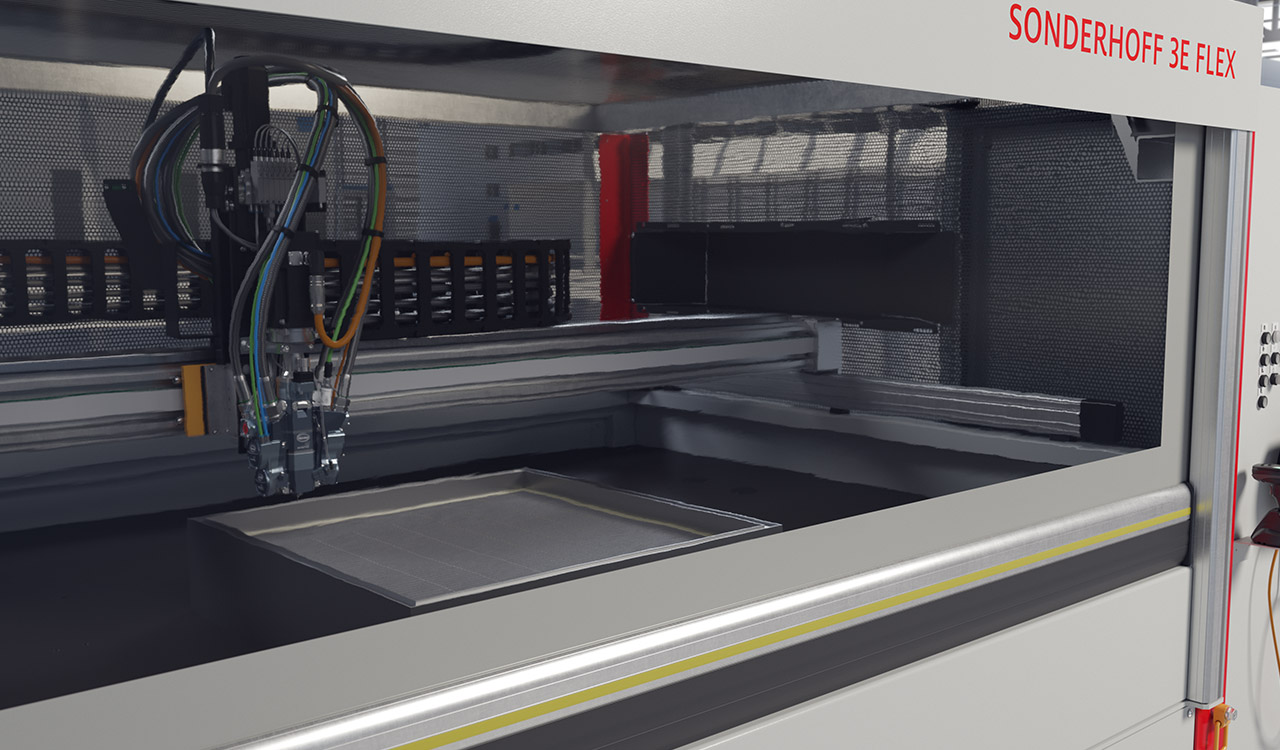

The 3-axis linear robot ensures repeatable guidance of the mixing head over the component to be processed.

Optional refilling station

The 3E FLEX dispensing cell can be optionally equipped with a refilling station for automatic material supply

More information to our refilling stationsControl cabinet

The control cabinet houses the control electronics, safety technology and industrial PC.

Mehr Informationen zu unseren SchaltschränkenMixing head MK 825 PLUS

MK 825 PLUS precision mixing head with high-pressure water rinsing or alternative component rinsing system

More information to our mixing headsHand scanner

Hand scanner for selecting the CNC and dosing program

Optional shuttle table

Optional shuttle table for feeding and discharging components in alternating shuttle mode

More information to our shuttle tablesAutomatisches SchnelllauftorAutomatic high speed door

To remove one or more components after the dosing process, the machine operator opens the high-speed door at the touch of a button

The compact class for 2K polyurethane and silicone applications

Place, plug & work!

Once the 3E FLEX is removed from its transport container, production can start without much preparation. Only connect the power, water, and compressed air supplies and prepare and fill the two material components of the selected 2K polyurethane or silicone system into separate material pressure tanks. With the 3E FLEX, even small and medium quantities can be produced very economically.

The dosing machine is equipped with an automatic high-speed door. Accordingly, the machine is CE-compliant so that no additional safety fences or light barriers are required – increasing efficiency and saving space and costs

With the dosing cell SONDERHOFF 3E FLEX (Economic, Efficient & Ecological), you can get to work right away: Place, plug & work!

Operation of the 3E FLEX dosing machine

The machine operator places one or more parts in the work area of the dosing cell on the prepared workpiece fixtures. He then closes the high-speed door by pressing a button so that the fully automatic material application can start. For this purpose, the CNC-controlled

MK 800 PLUS or MK 825 PLUS precision mixing head moves over the part contour to apply the material.

Multifunctional MP 2 Mobile Panel with integrated touchscreen

Switch for preselection "Mixing head maintenance position"

.

.

To remove one or more parts after the dispensing process, the high-speed door opens automatically or the operator opens it at the touch of a button.

Hand scanner for selecting the CNC and dispensing program

Operating mode control panel with warning lights, key switch for preselection of the operating mode, operating keys for high-speed door and EMERGENCY STOP with proven Sonderhoff SAFETY concept

The high-speed door after being closed.

3-Axis Linear Robot

The linear robot with toothed belt drive features good stiffness and acceleration values for repeatable guidance of the mixing head over the part being processed.

Features of Linear Robot:

- Max. traversing speed: 15 m/min

- Max. acceleration: 2 m/s²

- Repeat accuray: 1 mm +/- 0.5 mm

- Traversing range x/y/z: 2,500 x 1,250 x 300 mm

- Work/Table height: 1,000 mm (optionally reducable down to 700 mm)

Maximum traversing range and part size

The MK 800/825 PLUS is precisely guided by an integrated 3-axis linear robot in the traversing range of 2,500 x 1,250 x 300 mm (x/y/z).

The standard component height to be processed with the 3E FLEX can be extended from 300 mm to 600 mm.

The standard height of the work table is 1,000 mm. With the 3E FLEX it can be varied down to 700 mm.

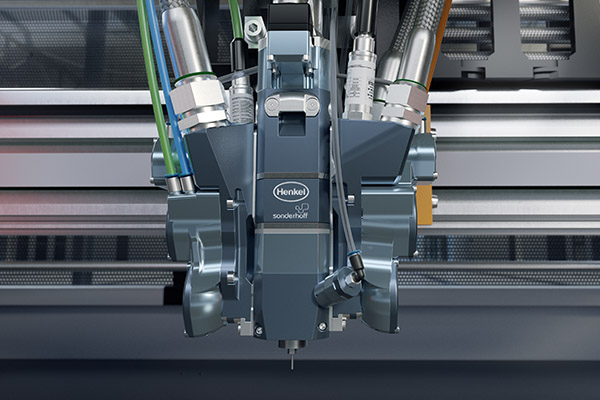

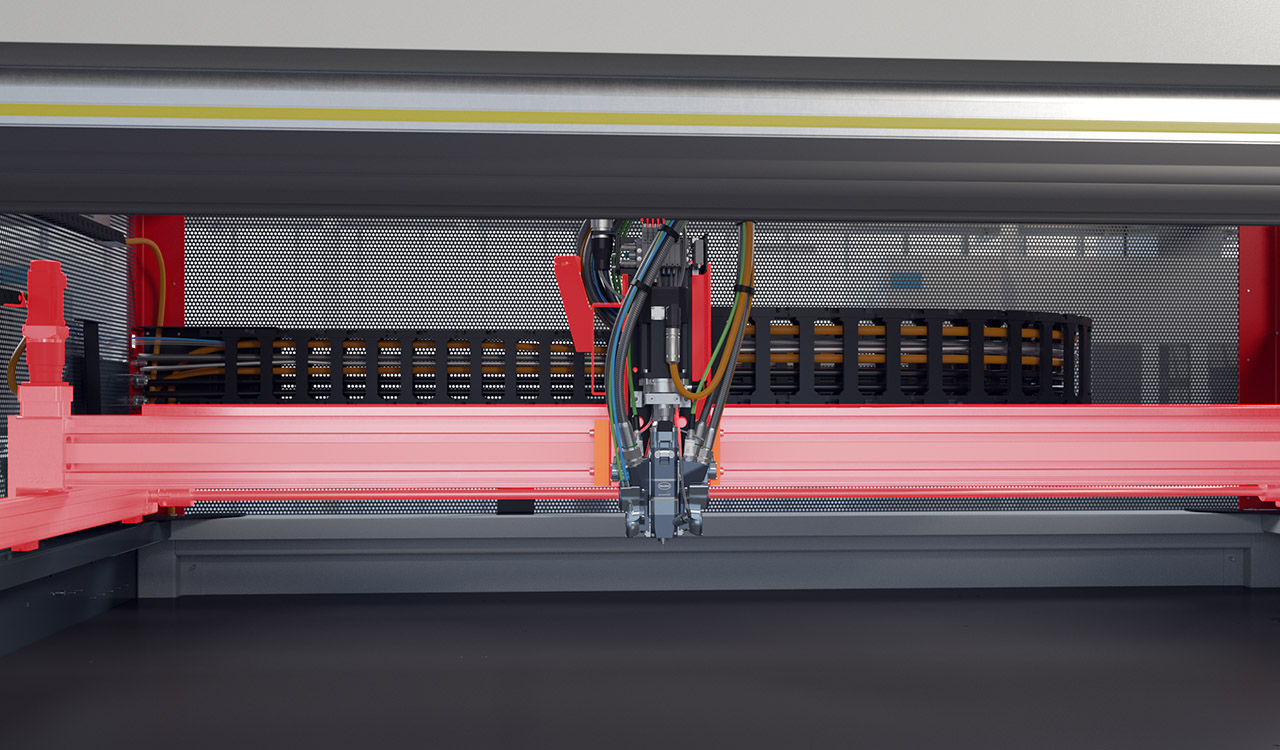

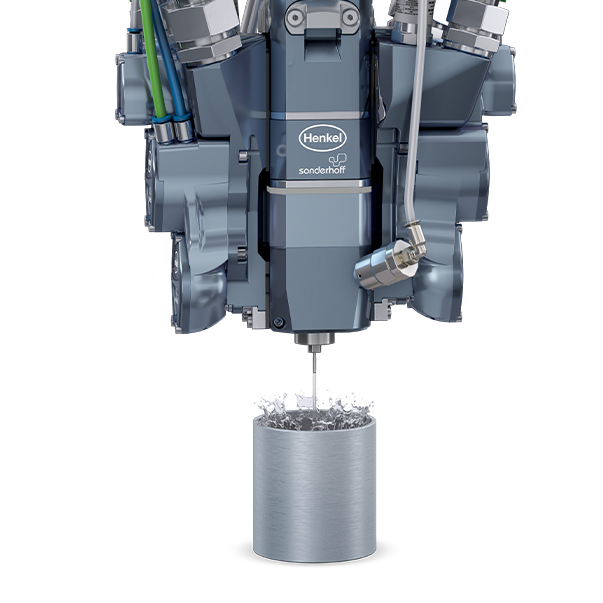

The MK 800 und 825 PLUS

2-Component Mixing Head with dynamic mixing and high-pressure water rinsing

In the SONDERHOFF 3E FLEX dosing cell, the MK 800/825 PLUS precision mixing head is used for processing a 2K material system. In the mixing head, the material components are mixed dynamically and homogeneously and dosed onto the part in precise quantities.

- Direct stack injection of the components

- Electronically adjustable stirrer speed

- Special stirrer design enables gentle material mixing

- Blowing air needle valve for drying the mixing system

- Low-drip, low-maintenance nozzle shut-off system STOP-DROP DVS 3

- Simple stroke adjustment by means of an adjusting wheel

- Material pressure measurement on the dosing valve

- Mixing chamber temperature sensor

- Mixing ratio infinitely variable from 1 : 100 to 100 : 1

- Dosing capacity MK 800 PLUS: 3.0 to 100 g/s

- Dosing capacity MK 825 PLUS: 0.2 to 3,0 g/s

-

Sensor-controlled 2-component mixing head with high-pressure water rinsing and dynamic mixing of liquid to highly viscous polymeric reaction materials for foam gasketing, bonding and potting processes

-

High-pressure water rinsing for ecological cleaning of the mixing system

-

Alternative: rinsing with A-component

-

Servopneumatically and hydromechanically controlled precision valves for precise dosing

-

Can also be equipped with stub lines for bonding or potting applications

-

Weight-reduced construction, modular designed, blue-gray anodized

-

Size-optimized, functional V-shaped design to increase the degrees of freedom

-

Robust and maintenance-free design made of high-strength aluminum alloy and chrome steel

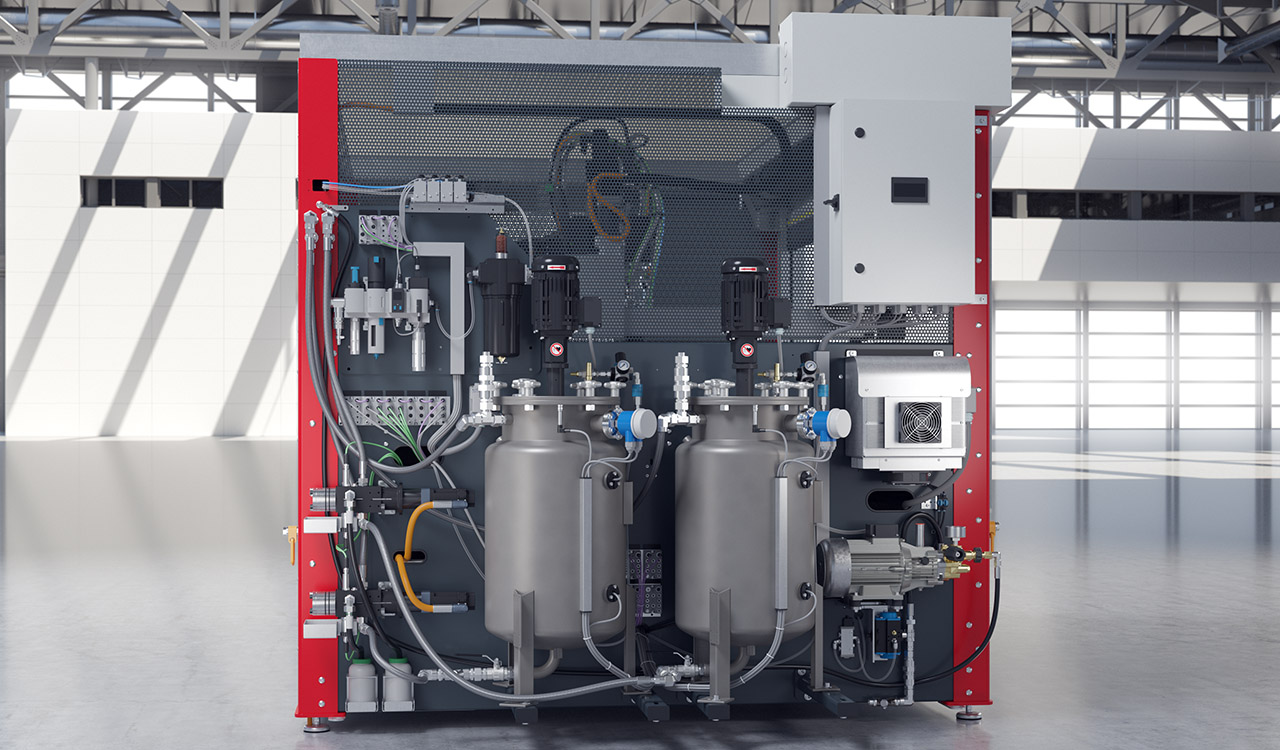

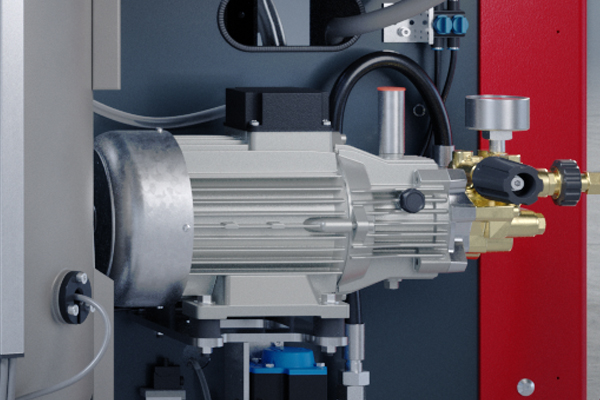

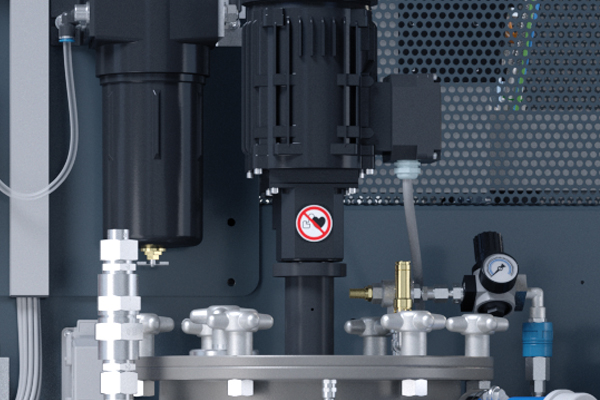

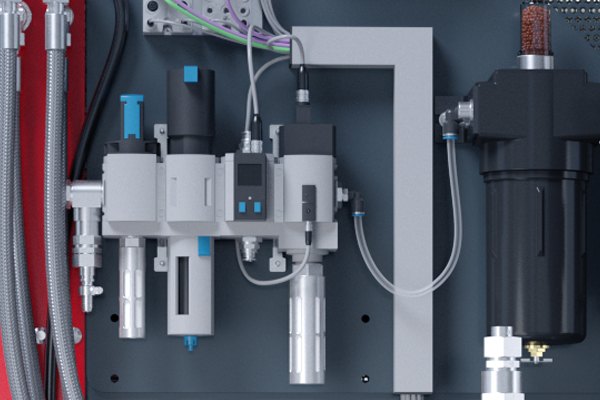

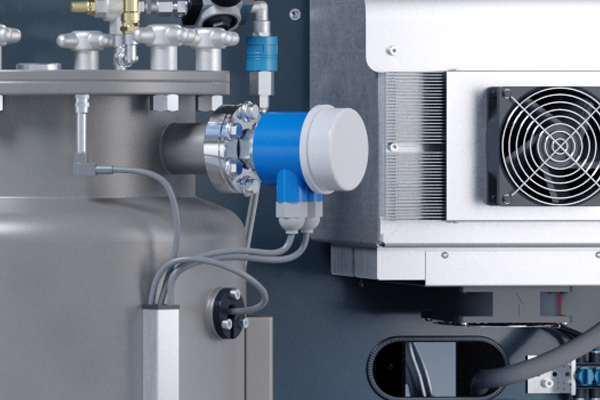

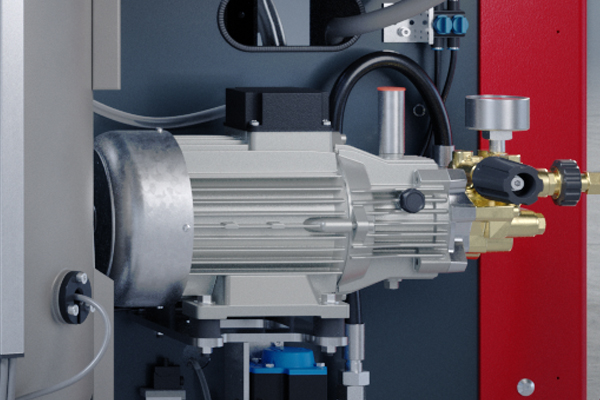

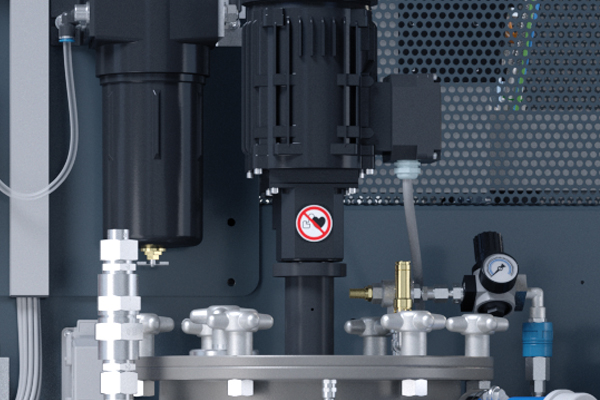

Dosing machine components and material tanks

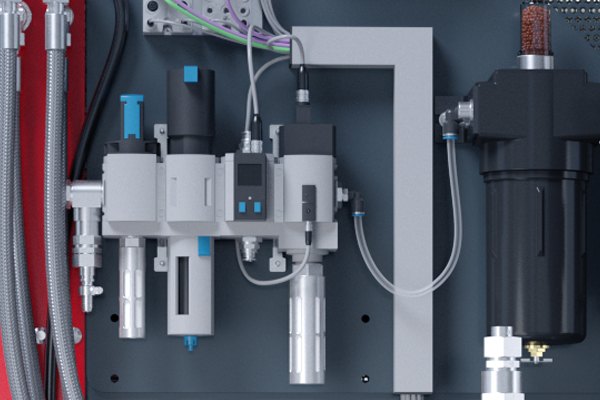

In the SONDERHOFF 3E FLEX dosing cell, the dosing machine components are attached to the left side of the cell, for example: the precision gear pumps, the compressed air connection and dryer, the maintenance unit as well as the optional Peltier device for mixing head cooling and the high-pressure water unit for ecological mixing head rinsing.

The double-walled material pressure tanks in the optimized sizes are also mounted on the cell chassis on the left side, either for the asymmetrical mixing ratios of the A and B components of the 2K polyurethane systems or for the symmetrical mixing ratios of the 2K silicone systems. The material pressure tanks of the 3E FLEX can be flexibly configured as required, either for both material components 24 or 44 liters or in combination for one component 24 and the other 44 liters.

For heating or cooling the material in the pressure tank, we offer an optional precision temperature control unit, which can be used to influence the reactivity behavior of the 2K material systems.

The material pressure tanks are equipped with various sensors that indicate whether the pressure tank needs to be refilled or is completely empty. For the material pressure tanks, an optional extension with an automatic refilling station for continuous material supply is possible on request. For this case, there is an overfill protection on the pressure tanks.

At a glance:

3E FLEX for 2K Silicone Systems

Precision gear pumps

Optional: Peltier device for mixing head cooling

High-pressure water device for the effective and ecological mixing head rinsing

Material pressure tank with optimized size for symmetrical mixing ratios

Material pressure tank with optimized size for symmetrical mixing ratios

Agitator for homogenization of A component

Compressed air connection and dryer

Overfill protection for use with an optional refilling station

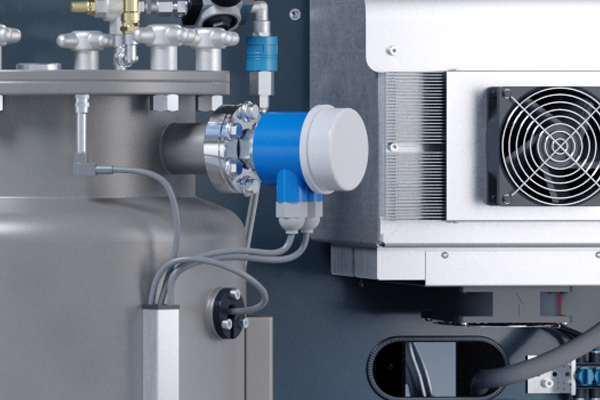

Capacitive sensors for level control

Optional: precision temperature device

Control Cabinet with main switch for the high-speed door

Precision gear pumps

Optional: Peltier device for mixing head cooling

High-pressure water device for the effective and ecological mixing head rinsing

Material pressure tank with optimized size for symmetrical mixing ratios

Material pressure tank with optimized size for symmetrical mixing ratios

Agitator for homogenization of A component

Compressed air connection and dryer

Overfill protection for use with an optional refilling station

Capacitive sensors for level control

Optional: precision temperature device

Control Cabinet with main switch for the high-speed door

Precision gear pumps

Precision gear pumps for 2K silicone systems: flow rate 0.75 ccm/U for A and B component

Optional: Peltier device for mixing head cooling

High-pressure water device for the effective and ecological mixing head rinsing

Use of approx. 200 ml of tap water per cleaning operation at an adjustable pressure of 80 - 130 bar, no solvents required for cleaning, reduction of disposal costs for solvents, no pollution by solvent evaporation or bad odor, cost saving - no extraction system required

Material pressure tank with optimized size for symmetrical mixing ratios

Material pressure tank, flexibly combinable, with level sensors, safety pressure valve (TÜV type-tested), overfill protection and shut-off ball valve, with compressed air fittings and compressed air reducing valves for prepressure control of the tank pressures

Material pressure tank with optimized size for symmetrical mixing ratios

Material pressure tank, flexibly combinable, with level sensors, safety pressure valve (TÜV type-tested), overfill protection and shut-off ball valve, with compressed air fittings and compressed air reducing valves for pre-pressure control of the tank pressures

Agitator for homogenization of A component

An automatic agitator for the material pressure tank of A component and optionally for B component prevents material sedimentation and ensures constantly homogeneous material.

Compressed air connection and dryer

Overfill protection for use with an optional refilling station

Capacitive sensors for level control

Optional: precision temperature device

Optional: precision temperature device for material heating and cooling in the pressure tank

Control Cabinet with main switch for the high-speed door

3E FLEX for 2K PUR Systems

Optional: Peltier device for mixing head cooling

Material pressure tank with optimized sizes for asymmetric mixing ratios

Material pressure tank with optimized sizes for asymmetric mixing ratios

High-pressure water rinsing unit for effective and ecological mixing head rinsing

Compressed air connection, dryer and maintenance unit

Agitator for homogenization of the A-component

Plate-split filter for the B component

Optional: Precision temperature control unit for heating or cooling the material in the pressure tank

Overfill protection for use with an optional refill station

Capacitive sensors for level control

Control Cabinet with main switch for the high-speed door

Optional: Peltier device for mixing head cooling

Material pressure tank with optimized sizes for asymmetric mixing ratios

Material pressure tank with optimized sizes for asymmetric mixing ratios

High-pressure water rinsing unit for effective and ecological mixing head rinsing

Compressed air connection, dryer and maintenance unit

Agitator for homogenization of the A-component

Plate-split filter for the B component

Optional: Precision temperature control unit for heating or cooling the material in the pressure tank

Overfill protection for use with an optional refill station

Capacitive sensors for level control

Control Cabinet with main switch for the high-speed door

Optional: Peltier device for mixing head cooling

Peltier device for mixing head cooling

Material pressure tank with optimized sizes for asymmetric mixing ratios

Material pressure tank, flexibly combinable, with level sensors, safety pressure valve (TÜV type-tested), overfill protection and shut-off ball valve, with compressed air fittings and compressed air reducing valves for prepressure control of the tank pressures

Material pressure tank with optimized sizes for asymmetric mixing ratios

Material pressure tank, flexibly combinable, with level sensors, safety pressure valve (TÜV type-tested), overfill protection and shut-off ball valve, with compressed air fittings and compressed air reducing valves for prepressure control of the tank pressures

High-pressure water rinsing unit for effective and ecological mixing head rinsing

Use of approx. 200 ml of tap water per cleaning operation at an adjustable pressure of 80 - 130 bar, no solvents required for cleaning, reduction of disposal costs for solvents, no pollution by solvent evaporation or bad odor, cost saving - no extraction system required

Compressed air connection, dryer and maintenance unit

Agitator for homogenization of the A-component

An automatic agitator for the material pressure tank of the A component and optionally for the B component prevents material sedimentation and ensures constantly homogeneous material.

Plate-split filter for the B component

Optional: Precision temperature control unit for heating or cooling the material in the pressure tank

Overfill protection for use with an optional refill station

Capacitive sensors for level control

Control Cabinet with main switch for the high-speed door

Air loading, temperature control and material evacuation

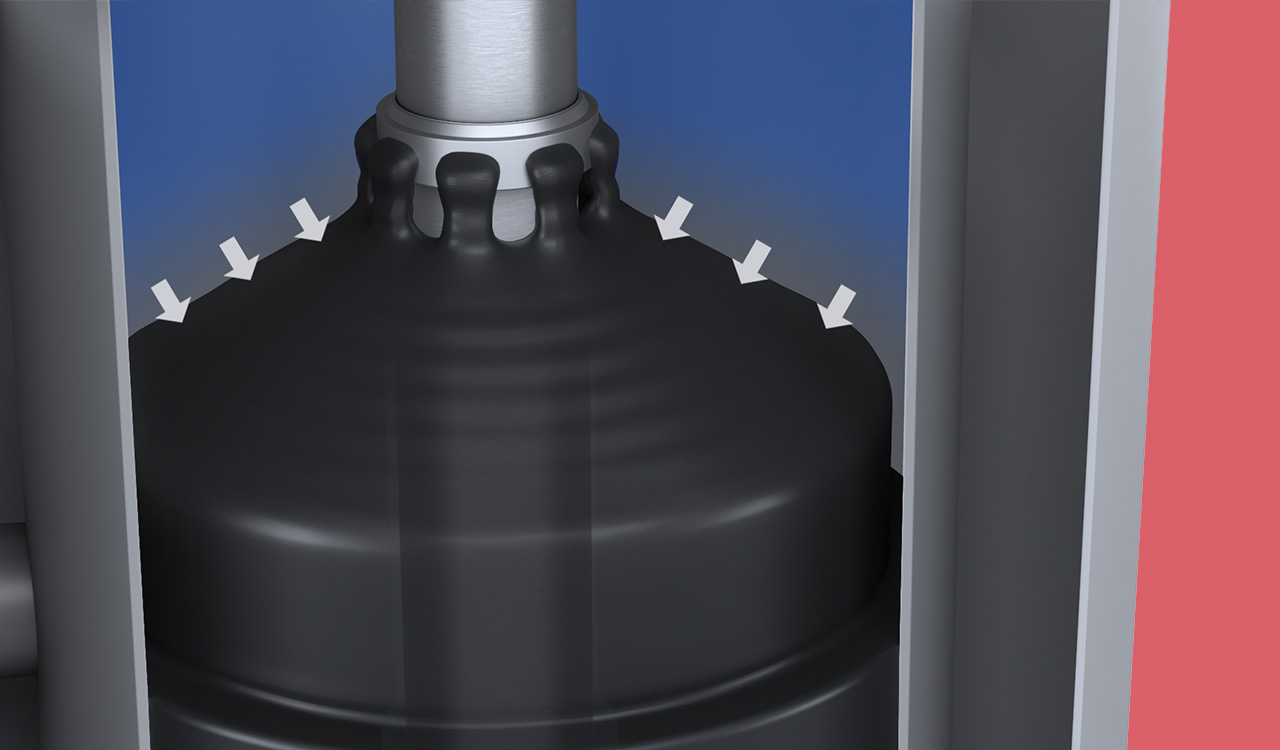

Air loading in the material pressure tank helps to produce the desired physical properties and cell structure of the foam. By adding compressed air to the material component, the density can be influenced.

Optional: temperature control unit for heating or cooling the material in the pressure tank

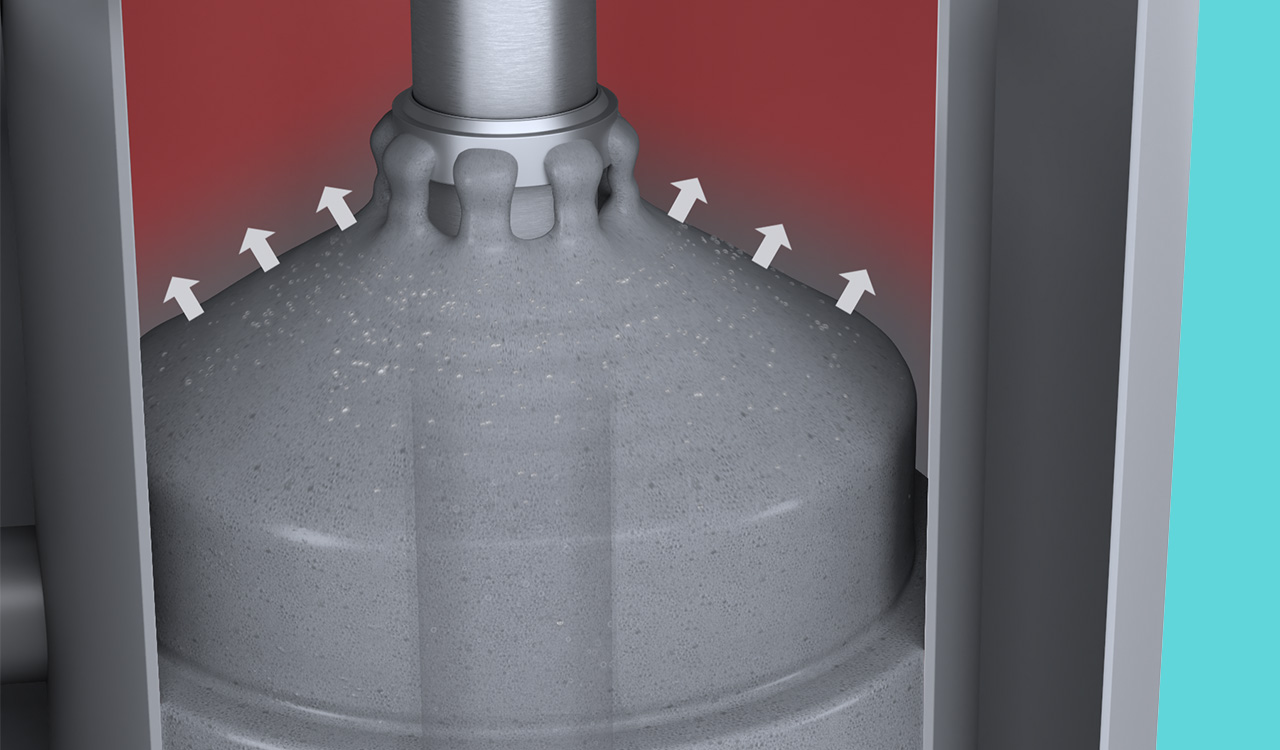

Air loading in the thin film process

Compressed air cushion acts on material surface

Druckluftpolster wirkt auf Materialoberfläche

Material is continuously conveyed from the pressure tank bottom through a riser and fed back onto the cone-shaped surface as a thin film. Due to the air loading, the density changes and the material becomes lighter.

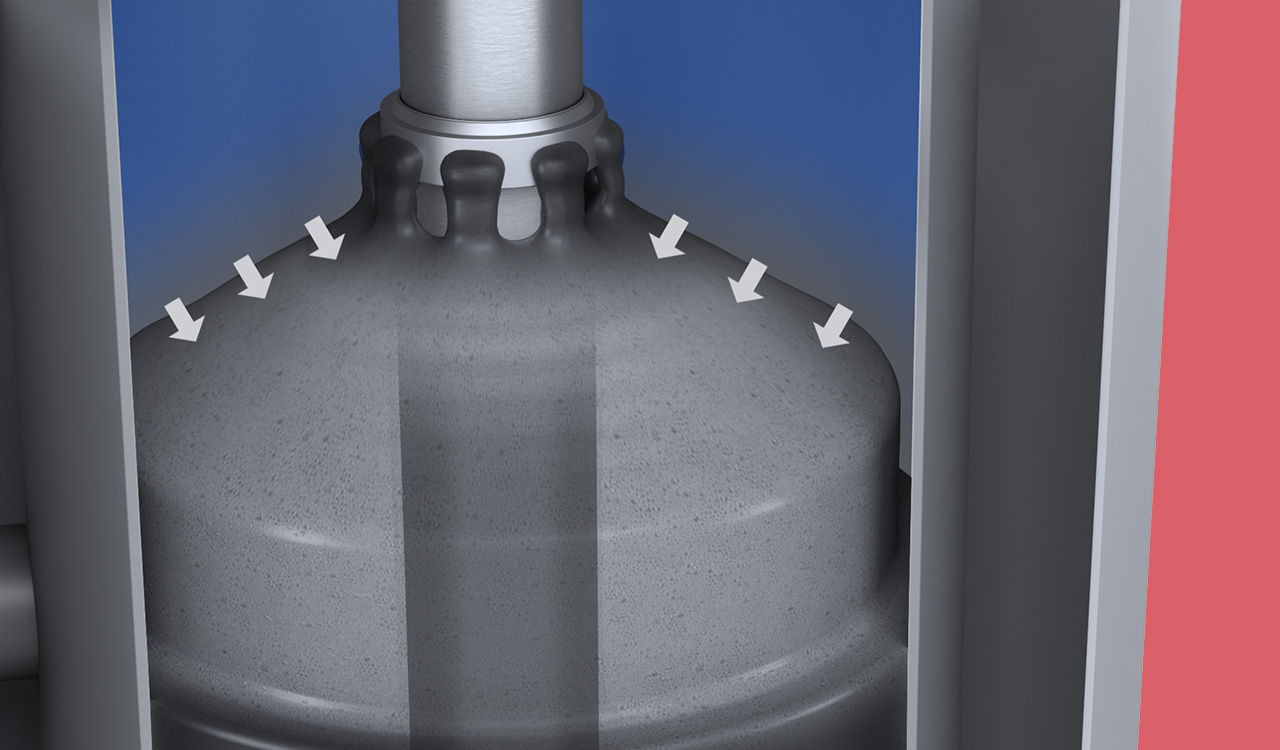

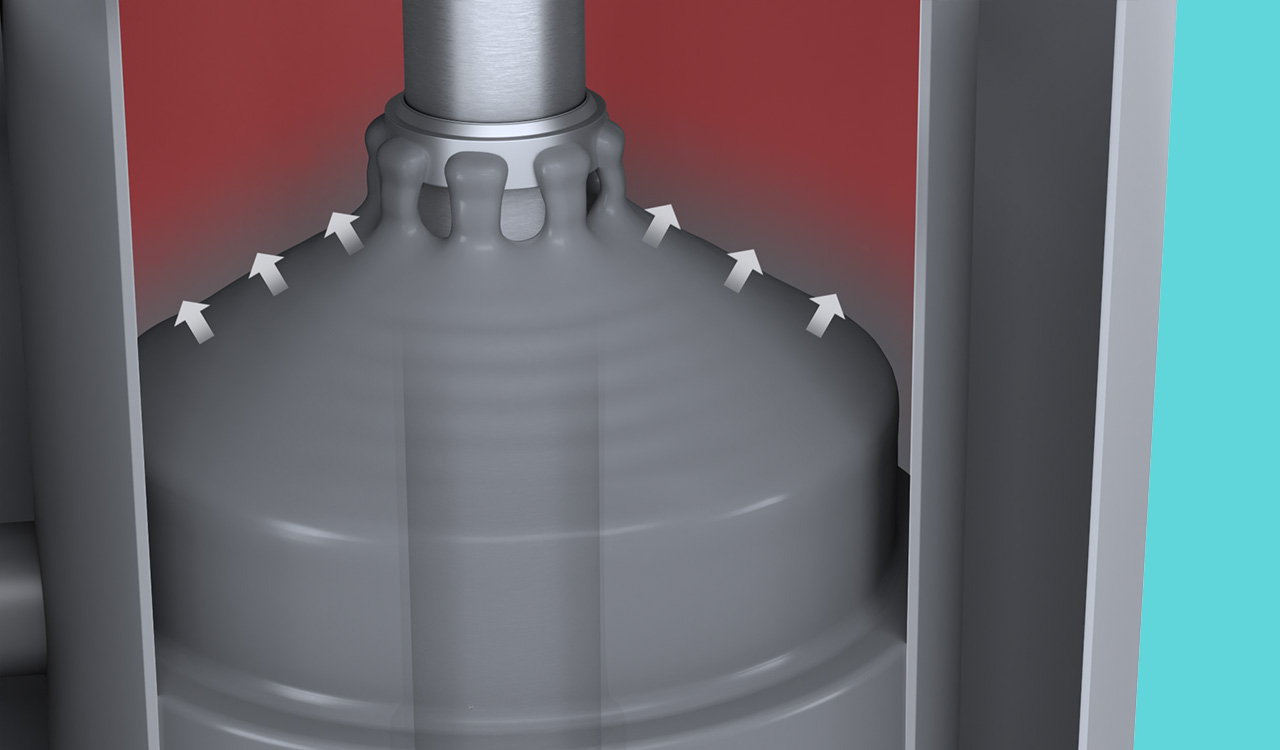

Material evacuation in the thin film process

Vacuum acts on the material surface.

Vakuum drückt auf Materialoberfläche .

Material is continuously conveyed from the pressure tank bottom through a riser and fed back onto the cone-shaped surface as a thin film. This process continuously reduces and completely dissolves the air bubbles in the material.

Automation and Configuration of the 3E FLEX Dosing Cell

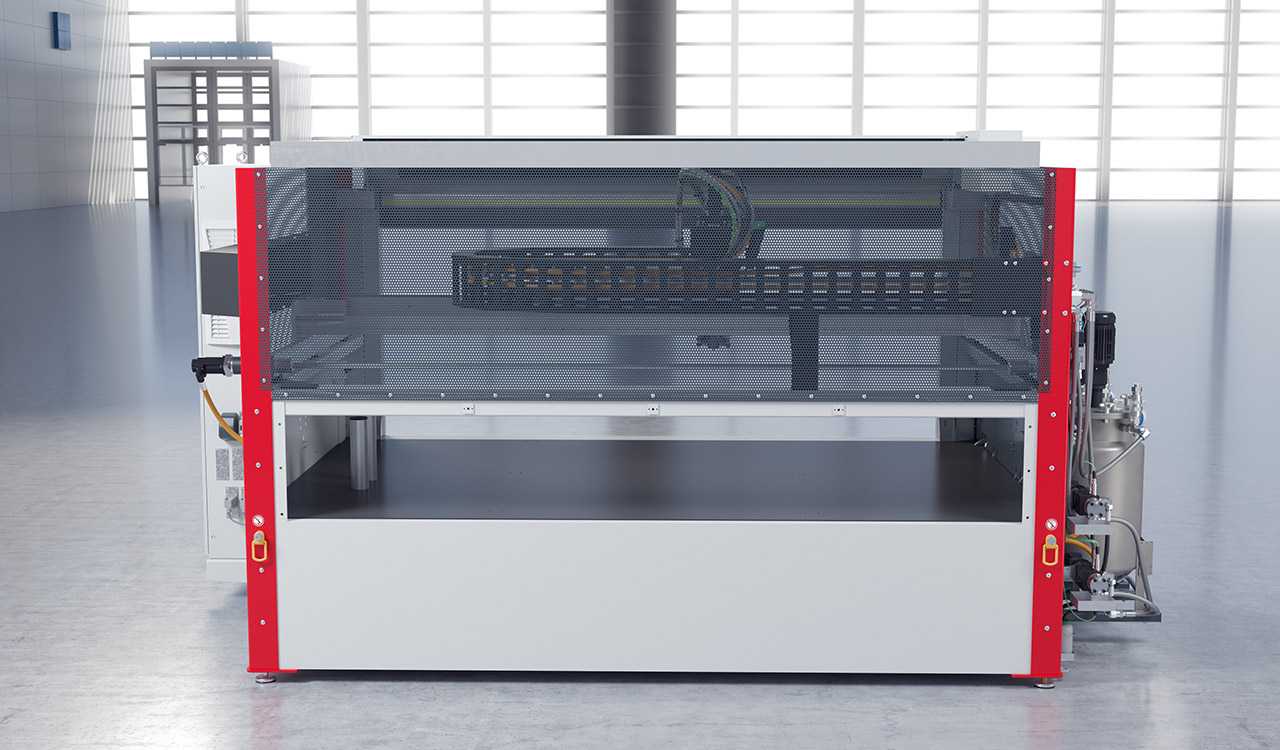

Another advantage for more flexibility is the variable work/table height in the dosing cell, allowing part heights from 300 to 600 mm. The work/table height is 1,000 mm as standard and can be reduced to 700 mm, for example, to integrate production automation.

For this purpose, the cover plate on the front and rear of the dosing cell can be removed so that, if required, a transfer belt running through the cell can be installed for clocking in and out the parts.

Front of the 3E FLEX with upper removable cover plate.

Height of the table top 1,000 mm.

.

Front of the 3E FLEX: The front and rear cover plate has been removed to incorporate automation: table top height 700 mm.

Optional Shuttle Table for the 3E FLEX Dosing Cell

As an option, the parts can also be loaded on an attachable sliding/shuttle table by manually moving the mounting plates. With this solution, a machine operator loads the two mounting plates with the parts in alternation. The parts are positioned in workpiece fixtures that are mounted on the coated multiplex mounting plates.

More informationen about the shuttle tables of the 3E series

Further components of the 3E FLEX dosing cell

Control Cabinet

The switch cabinet is the expandable future-proof control center of the SONDERHOFF 3E FLEX dosing cell with DM 50x technology. It includes the electrical distribution as well as the control and safety technology for the dosing machine and the CNC control of the 3-axis linear robot installed in the cell.

Multi-functional MP 2 mobile panel

The SONDERHOFF 3E FLEX dosing cell is designed to enable the operator to perform a wide variety of tasks easily and safely. The system is operated via the easy-to-use, multi-functional Sonderhoff MP 2 mobile panel with integrated 10.1“ touchscreen. This makes the contour programming of components significantly simpler.

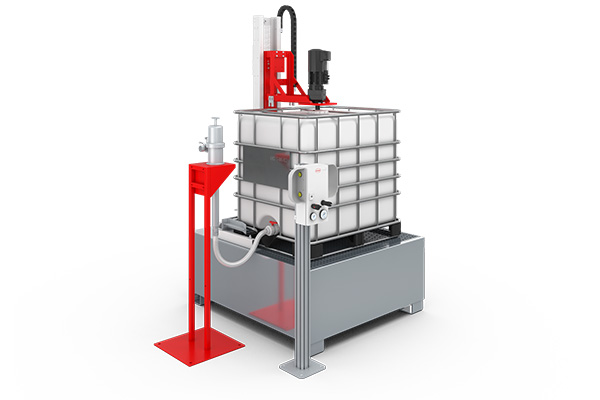

Optional automatic refilling stations

The 3E FLEX dosing cell can optionally be equipped with a refilling station for automatic material supply. This ensures material-specific preparation, homogeneous consistency and a continuous supply of materials to the component containers of the mixing and dosing system – without exposure to or contamination of the products to be filled.

Technical Service

The productivity of a machine is largely determined by its reliable availability. That's why we ensure that downtimes caused by faults and maintenance-related production interruptions are intelligently minimized.

Our service package includes the interplay of proactive in-house service, for example through risk analyses, as well as experienced, competent on-site service and responsive online service, keyword: Remote Collaboration. With this, we support you in the safe planning and execution of your production processes as well as predictive maintenance.