Dosing cell 3E SIL

Cellular mixing and dosing machine for the processing of 2K silicone systems

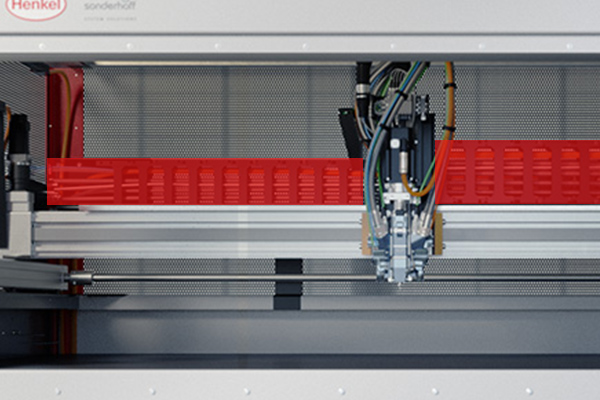

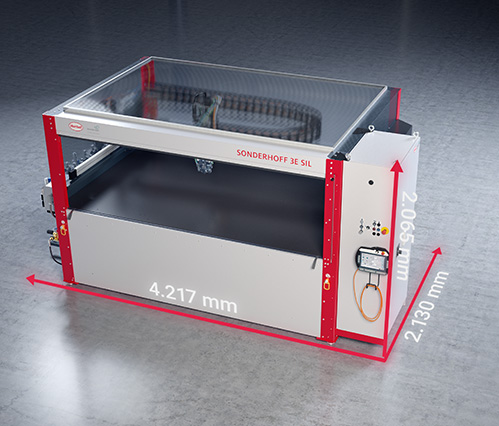

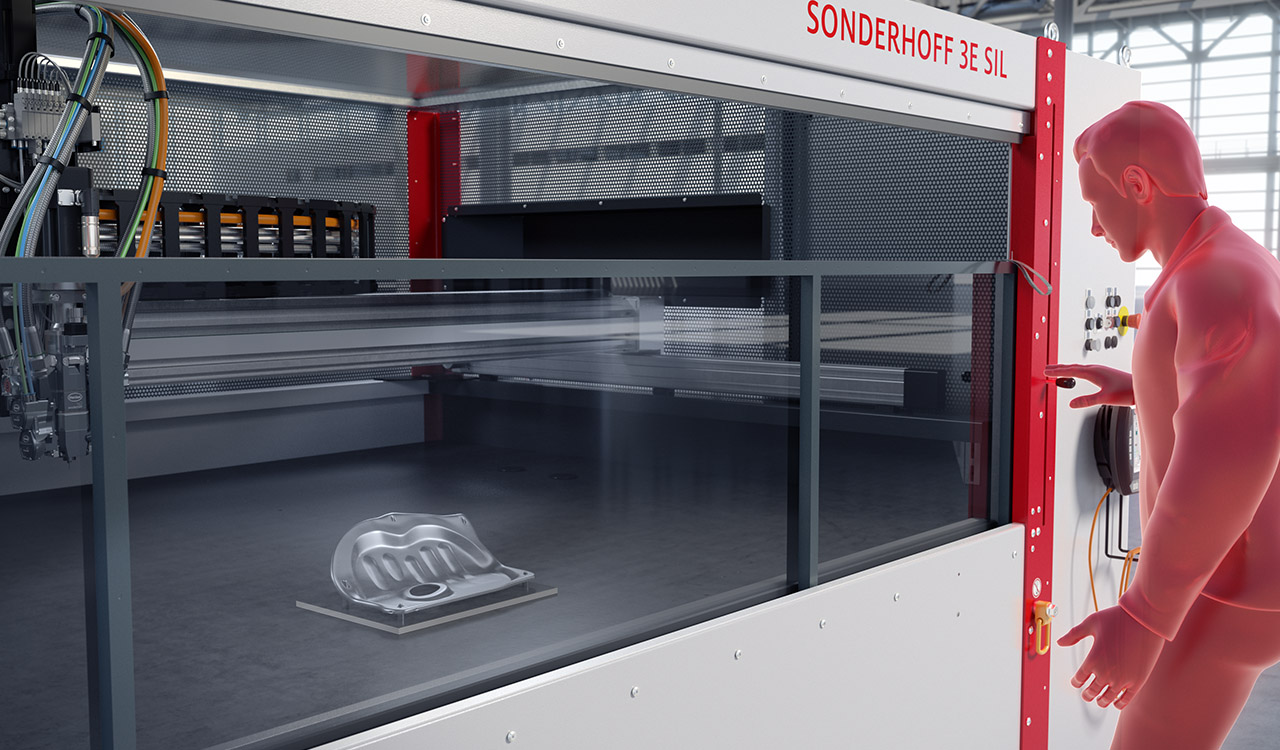

The standardized SONDERHOFF 3E SIL dosing cell is designed for simple standard applications with Formed-In-Place (FIP) technology and processes and dispenses very precise 2k silicone systems with symmetrical mixing ratios.

You can use the 3E SIL for component sealing with 2-component silicone foam or for non-foamed 2K material systems such as potting compounds and silicone-based adhesives.

The components are positioned either manually in the working area of the dispensing cell or on the optionally available exchangeable/sliding table. For oversized components, the two sliding tables can be connected to form a large work table.

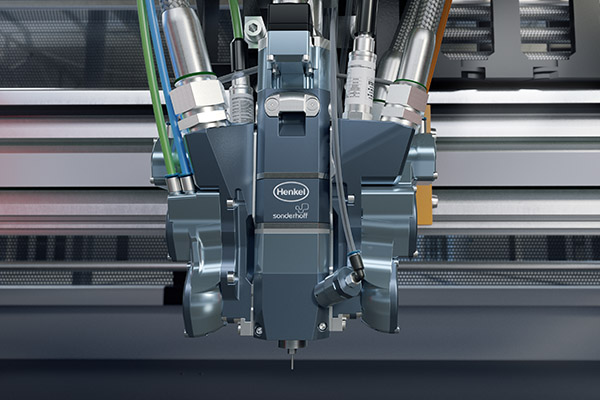

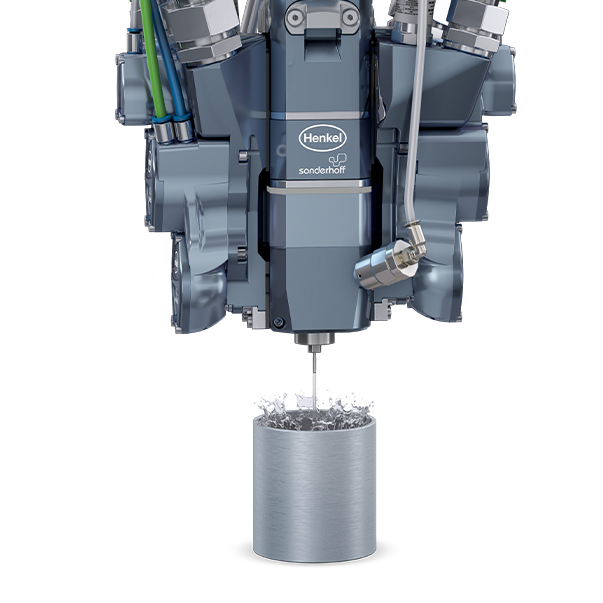

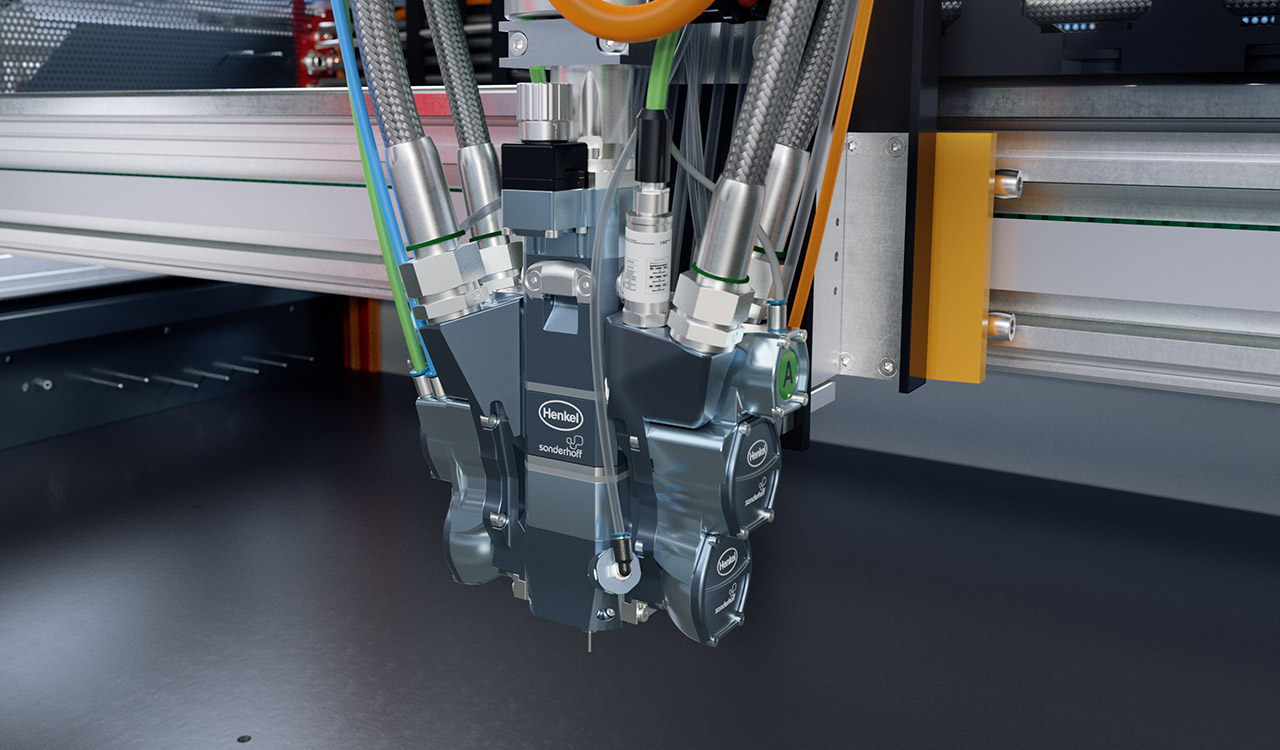

On the 3E SIL, the MK 825 PLUS precision mixing head ensures dynamic and homogeneous mixing of the two material components. It doses precisely according to the defined mixing ratio - a prerequisite for high quality silicone applications.

The 2-component silicone system used is applied to the component with repeat accuracy and fully automatically via the CNC-controlled mixing head.

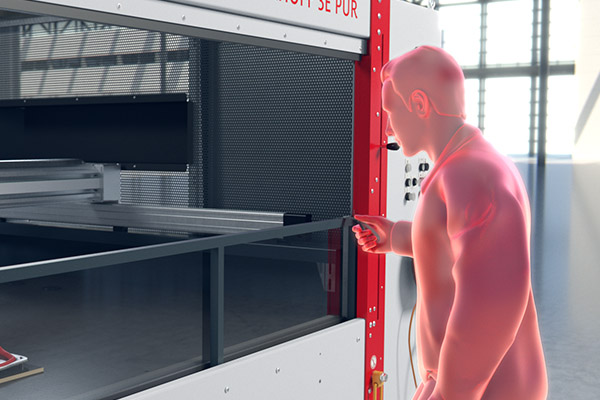

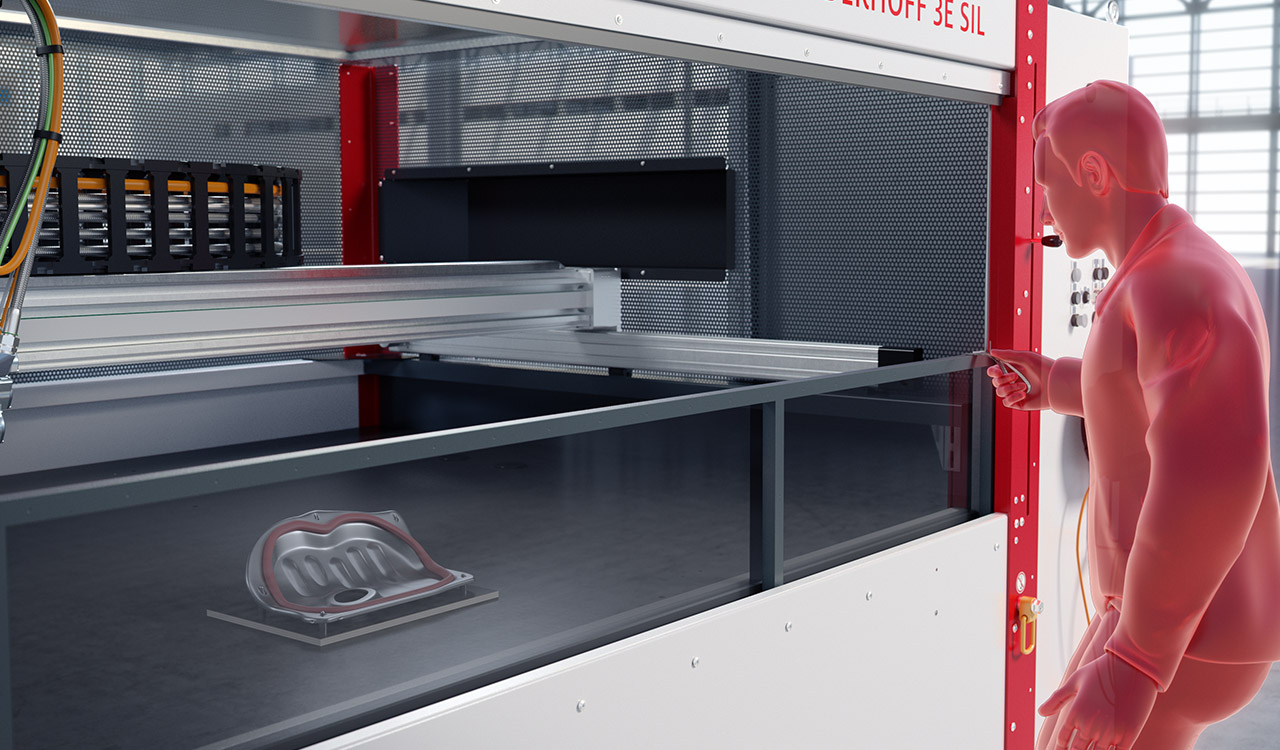

The maximum mixing head travel range of the linear robot is 2,500 x 1,250 x 250 mm (x/y/z). A manually operated lift door separates the machine operator from the work area of the dispensing cell, which is thus CE-compliant.

An attractive entry-level price of the 3E SIL enables very short payback times and the high degree of standardization usually shortens delivery times.

Optimized process evaluation and control

The new MK 825 PLUS mixing head in the 3E SIL features innovative improvements. They ensure maximum process stability in the fully automatic metering of the 2k silicone systems used.

The sensors installed in the mixing head continuously supply measurement data that enable the machine operator to monitor critical process parameters of the dispensing job during production. The measurement data also informs when preventive maintenance of wear parts becomes necessary.

The automatic logging of all system, material and process data ensures the traceability of the production sequence at all times.

The new video for the dosing cell SONDERHOFF 3E PUR and SIL

Here you can find out how easy it is to commission and operate the 3E dosing cell – place, plug & work! The video also informs you about its functionality, and where the individual machine components are located in the system, as well as how the optionally available shuttle table can be attached to the dosing cell in self-assembly.

Dispensing Cell 3E SIL

The entry-level model for typical standard applications

Dosing components and material containers

Mixing head MK 825 PLUS

Linear robot

Control cabinet

Operation & programming via the Sonderhoff user interface

Lifting door

Filling shot and rinse water tanks

Shuttle / sliding table (optional)

Optional refilling station

Dosing components and material containers

Mixing head MK 825 PLUS

Linear robot

Control cabinet

Operation & programming via the Sonderhoff user interface

Lifting door

Filling shot and rinse water tanks

Shuttle / sliding table (optional)

Optional refilling station

Dosing components and material containers

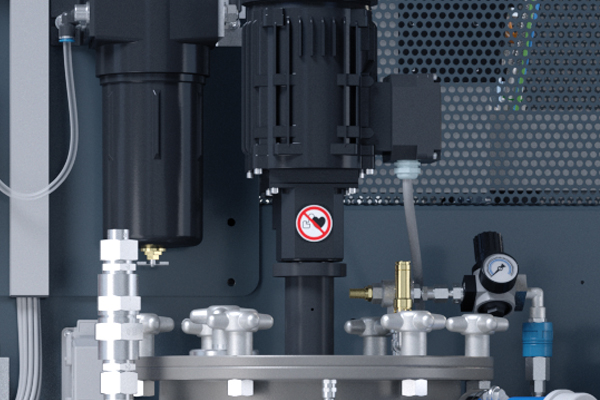

At the front left side are e.g. the precision gear pump, the high-pressure water unit for mixing head rinsing, and the material pressure tank for the A and B components.

More to our dosing machinesLinear robot

The 3-axis linear robot ensures repeatable guidance of the mixing head over the component being processed.

Control cabinet

The control electronics, servo and safety engineering, and the industrial PC are installed in an air-conditioned switch cabinet.

More to our control cabinetsOperation & programming via the Sonderhoff user interface

The multi-functional MP 2 Mobile Panel with touchscreen (10.1” WXGA TFT) for program- ming and operating the dosing machine.

More to our Mobile PanelLifting door

Lifting door with safety monitoring for manual closing and opening of the mixing head travel area in the dosing cell ensures the CE conformity of the dosing system.

Filling shot and rinse water tanks

At the front right side is the opening for removing the filling shot and rinse water tanks.

Shuttle / sliding table (optional)

Shuttle / sliding table with two alternately operated manual mounting plates

More to our shuttle tablesOptional refilling station

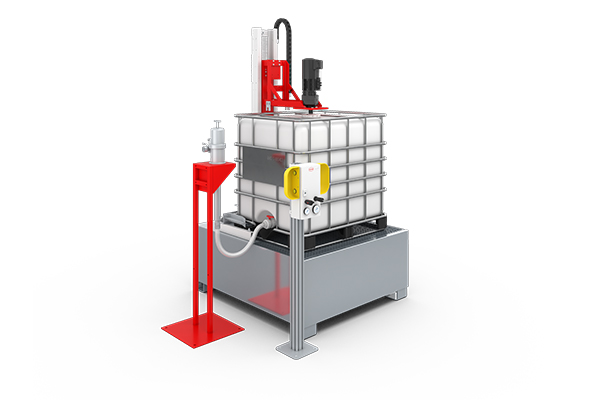

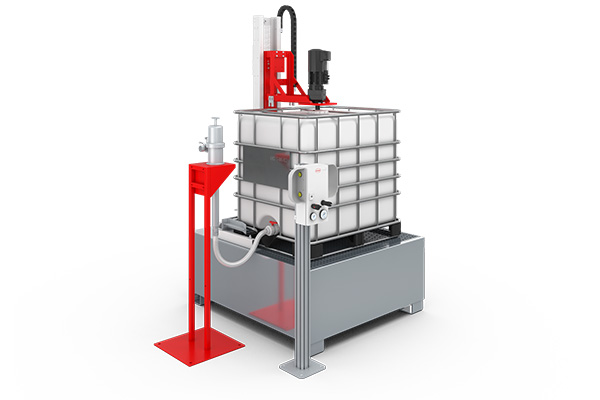

The dosing cell 3E SIL can optionally be equipped with a refilling station for automatic material supply.

More to our refilling stationsThe compact class for 2K silicone applications

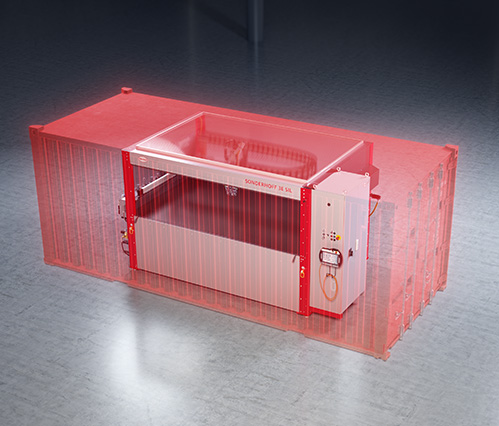

Place, plug & work!

Once the 3E SIL is removed from its transport container, production can start without much preparation. Power, water and compressed air just have to be connected and the two material components of the chosen 2K silicone system filled into and prepared in the separate material pressure tanks. With the 3E SIL, even small and medium quantities can be produced very economically.

The dosing machine is equipped with a manually operated lifting door. Accordingly, the machine is CE-compliant, so that no additional safety fences or light barriers are required – this boosts efficiency, saving space and costs.

With the dosing cell SONDERHOFF 3E SIL (Economic, Efficient & Ecological), you can get to work right away: Place, plug & work!

MK 825 PLUS

2-component mixing head with high-pressure water rinsing and dynamic mixing

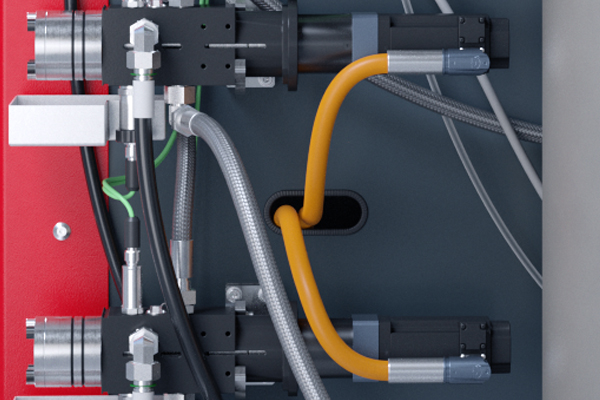

In the SONDERHOFF 3E SIL dispensing cell, the MK 825 PLUS precision mixing head is used for two material components. In the mixing head, the material components are mixed dynamically and homogeneously and dosed onto the component in precise quantities for material application.

The MK 825 PLUS is designed for a dosing rate of 0.2 to 3.0 g/s with a continuously adjustable mixing ratio of 1 : 10 to 10 : 1.

- Size-optimized, functional V-design to increase the degrees of freedom

- Robust and maintenance-free design made of high-strength aluminum alloy and chrome steel

- Direct stack injection of components

- Electronically adjustable mixer speed

- Special mixer design enables gentle material mixing

- Blast air needle seat valve for drying the mixing system

- Low-drip and low-maintenance nozzle closing system STOP-DROP DVS 3

- Stroke adjustment can be easily adjusted by means of an adjusting wheel

- Material pressure measurement at the metering valve

- Mixing chamber temperature sensor

- Sensor-controlled 2-component mixing head with high-pressure water rinsing and dynamic mixing for liquid to highly viscous polymeric reactive materials for seal foaming, bonding and potting

- High-pressure water flushing for ecological cleaning of the mixing system using high-pressure needle seat valves for flushing water injection

- Alternative component flushing for flushing with the non-reactive component

- Servo-pneumatically and hydromechanically controlled metering valves for precise metering

- Weight-reduced modular design, blue-gray anodized finish

The mixing head is precisely guided within the travel range of 2,500 x 1,250 x 250 mm (x/y/z) by a 3-axis linear robot integrated into the cell. The linear robot with toothed-belt drive is characterized by its good stiffness. This allows the mixing head to be guided over the part being processed with very high repeatability.

TECHNICAL DATA |

MK 825 PLUS |

| Dimensions (H x W x D) mixing head |

248 x 204 x 151 mm |

| Working pressure |

to approx. 20 bar |

| Discharge capacity |

0.2 to 3.0 g/s |

| Dosing accuracy |

±1 % |

| Mixing head weight |

approx. 5.5 kg |

| Mixing ratio |

from 10 : 1 to 1 : 10 steplessly adjustable |

| Selectable mixer speed | from 1 to 4.500 U/min steplessly adjustable |

| Viscosity processing range |

Component A: 1.000 – 100.000 mPas (*); Component B: 200 – 1.000 mPas (*) |

* Depending on the mixing ratios, material viscosities and the selection of pumps, hoses and mixing elements.

Component handling and lift door operation

The machine operator places one or more parts on the prepared workpiece holder within the working area of the dosing cell. He then closes the lifting door with a hand lever at the front of the machine. The fully automatic application of material to the part can start. For this purpose, the CNC-controlled MK 825 PLUS precision mixing head moves over the part contour.

To remove one or more parts after the dispensing process, the machine operator opens the lifting door using either the hand strap mounted there or the lever.

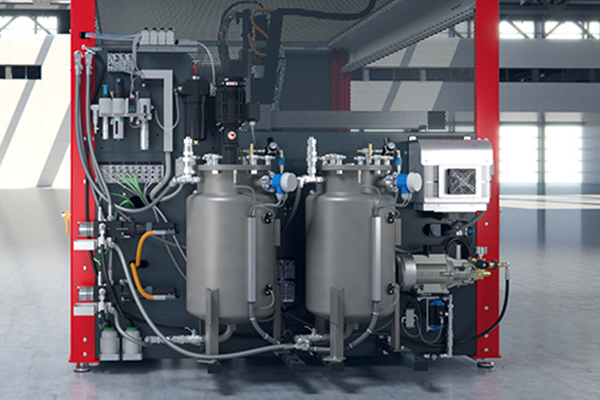

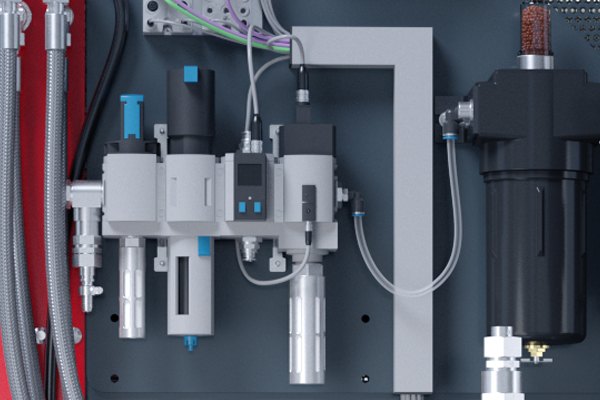

Dosing machine components and material containers

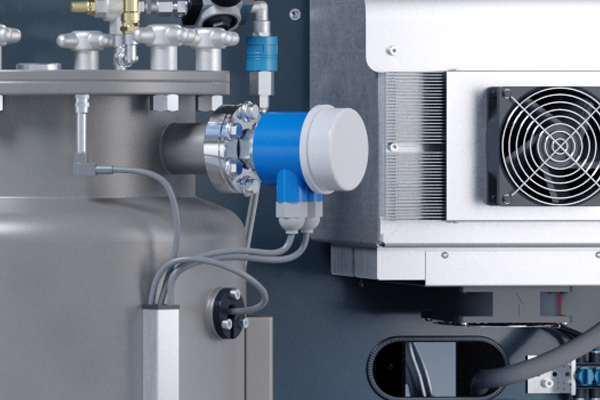

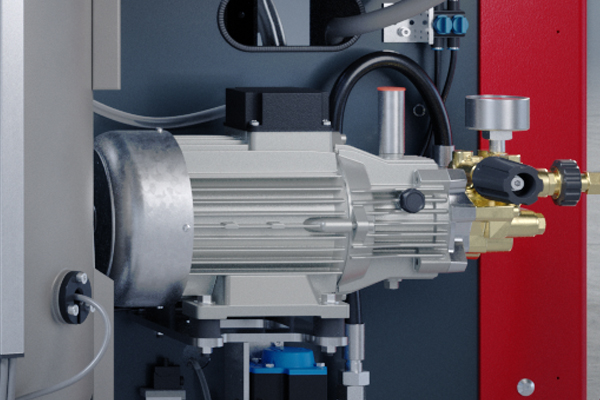

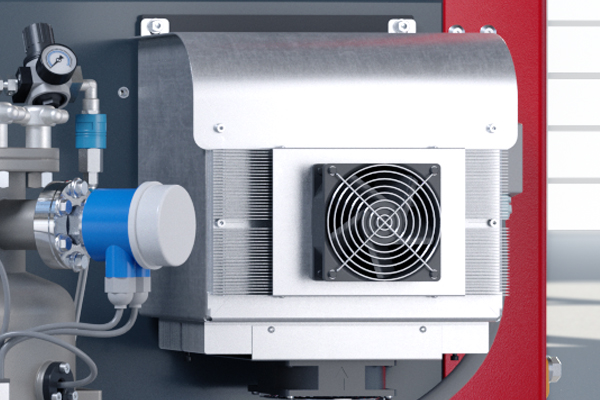

In the SONDERHOFF 3E SIL dosing cell, the dosing machine components are mounted on the side of the cell. This is where e.g. the precision gear pumps, compressed air connection and dryer, and the maintenance unit and high-pressure water unit for mixing head rinsing are located.

The double-walled material pressure tanks with optimized sizes for the symmetrical mixing ratios of the A and B components of the 2K silicone systems are also installed here. The material pressure tanks are equipped with various sensors, indicating whether the pressure tank is empty or needs to be refilled.

For the material pressure tanks, an extension with a refilling station for automating the material supply is possible on request. For that case there is an overfilling protection mechanism on the pressure tanks.

Material preparation for 3E SIL:

-

Material pressure tank with fill-level sensors, safety pressure valve (TÜV type-tested), overfilling protection and shut-off ball valve, with compressed air fittings and compressed air reducing valves for pre-pressure regulation of the tank pressures

-

44 l material pressure tank, double-walled, chrome-nickel steel for material component A

-

44 l material pressure tank, double-walled, chrome-nickel steel for material component B

-

Wire mesh filter cartridges and plate gap filters

-

Three-phase agitator running at 99 rpm for tank A

-

Automatic air loading

-

Optional: Material supply through refilling stations for containers from 20 to 1,000 liters

-

Precision gear pumps: Delivery rate 0.75 ccm/rev for the A and B components of the 2K silicone systems

-

Hose package: Steel-coated PTFE high-pressure hoses for the A and B components with stainless steel VA fittings, recirculation hose package

Dosing machine components and material containers at a glance

Compressed air connection, dryer and maintenance unit

Agitator for homogenization of the A component

Overfilling protection for the use of an optional refilling station

High-pressure water unit for effective and ecological mixing head rinsing

Capacitive sensors for filling level regulation

Material pressure tank with optimized dimensions for symmetrical mixing ratios

Material pressure tank with optimized dimensions for symmetrical mixing ratios

Precision gear pumps with 0.75 ccm/rev delivery rate of the A and B components of the 2K silicone systems

Peltier unit for cooling the MK 825 PLUS precision mixing head

Compressed air connection, dryer and maintenance unit

Agitator for homogenization of the A component

Overfilling protection for the use of an optional refilling station

High-pressure water unit for effective and ecological mixing head rinsing

Capacitive sensors for filling level regulation

Material pressure tank with optimized dimensions for symmetrical mixing ratios

Material pressure tank with optimized dimensions for symmetrical mixing ratios

Precision gear pumps with 0.75 ccm/rev delivery rate of the A and B components of the 2K silicone systems

Peltier unit for cooling the MK 825 PLUS precision mixing head

Compressed air connection, dryer and maintenance unit

Agitator for homogenization of the A component

Overfilling protection for the use of an optional refilling station

High-pressure water unit for effective and ecological mixing head rinsing

Capacitive sensors for filling level regulation

Material pressure tank with optimized dimensions for symmetrical mixing ratios

Material pressure tank with optimized dimensions for symmetrical mixing ratios

Precision gear pumps with 0.75 ccm/rev delivery rate of the A and B components of the 2K silicone systems

Peltier unit for cooling the MK 825 PLUS precision mixing head

The individual components of the 3E SIL dosing cell

Control Cabinet

The switch cabinet is the expandable future-proof control center of the SONDERHOFF 3E SIL dosing cell with DM 50x technology. It includes the electrical distribution as well as the control and safety technology for the dosing machine and the CNC control of the 3-axis linear robot installed in the cell.

Multi-functional MP 2 mobile panel

The SONDERHOFF 3E SIL dosing cell is designed to enable the operator to perform a wide variety of tasks easily and safely. The system is operated via the easy-to-use, multi-functional Sonderhoff MP 2 mobile panel with integrated 10.1“ touchscreen. This makes the contour programming of components significantly simpler.

Optional shuttle table

The SONDERHOFF 3E SIL dosing cell offers an attachable sliding table with manually shifting mounting plates as an alternative option for placement and processing of industrial parts for sealing, bonding, or potting. With this solution, a machine operator loads the two mounting plates with the components in an alternating sequence.

Optional automatic refilling stations

The 3E SIL dosing cell can optionally be equipped with a refilling station for automatic material supply. This ensures material-specific preparation, homogeneous consistency and a continuous supply of materials to the component containers of the mixing and dosing system – without exposure to or contamination of the products to be filled.

Technical Service

The productivity of a machine is largely determined by its reliable availability. That's why we ensure that downtimes caused by faults and maintenance-related production interruptions are intelligently minimized.

Our service package includes the interplay of proactive in-house service, for example through risk analyses, as well as experienced, competent on-site service and responsive online service, keyword: Remote Collaboration. With this, we support you in the safe planning and execution of your production processes as well as predictive maintenance.