Optional shuttle table for the 3E PUR, SIL and FLEX

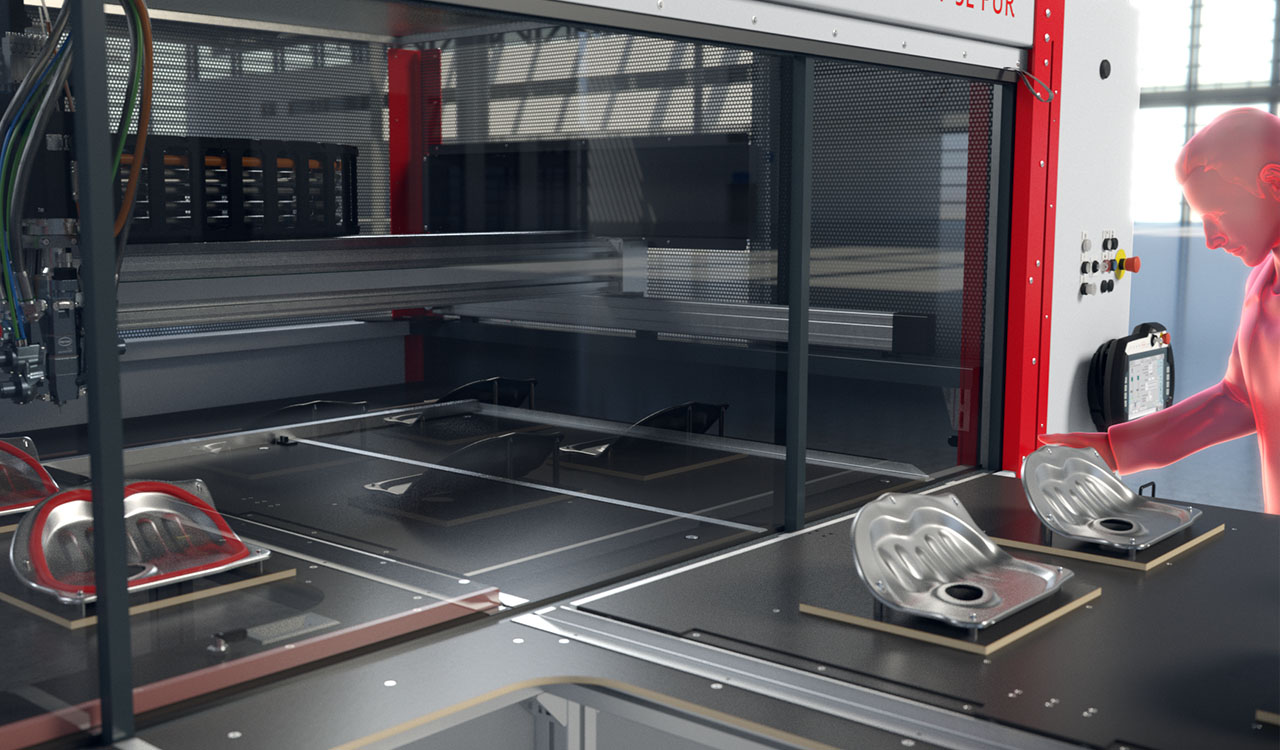

As an option for the SONDERHOFF 3E dosing cells, the processing parts can also be loaded on an attachable shuttle / sliding table by manually moving the mounting plates, which are made of coated multiplex. With this solution, a machine operator loads the two mounting plates with parts in alternation. The parts are positioned in workpiece fixtures that are fastened to the mounting plates.

The machine operator pushes the mounting plates into the work area of the dosing cell and closes the manual lifting door (3E PUR and 3E SIL) or the high-speed door (3E FLEX). He then starts the dispensing process.

Position, screw on, fine-adjust.

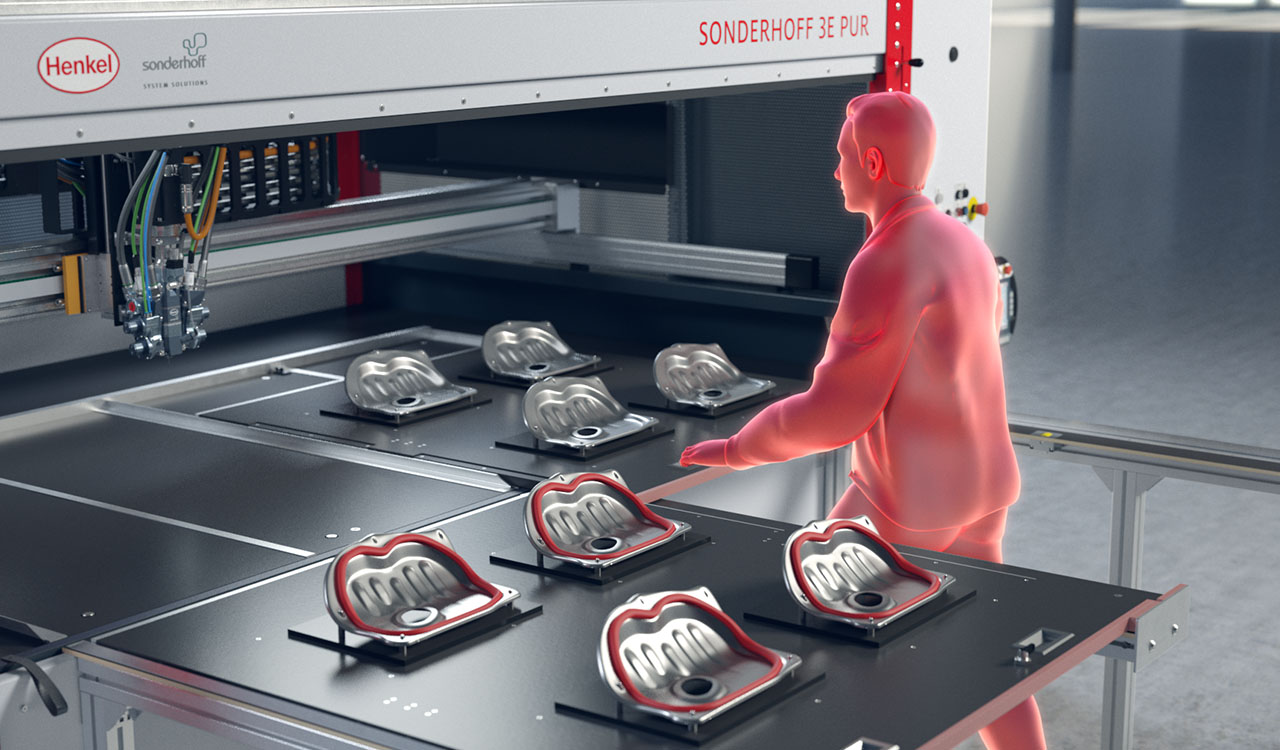

Alternating shuttle mode

The machine operator positions the parts on the prepared workpiece fixtures fastened on the mounting plates, while in the 3E PUR or 3E SIL dosing cell, with the manual lifting door closed, the CNC-controlled mixing head applies sealing material to the parts positioned on the other sliding table.

After the dispensing application, the machine operator opens the manual lifting door (3E PUR and 3E SIL) or the automatic high-speed door (3E FLEX) and pulls the sliding table with the finished parts out of the working area for removal.

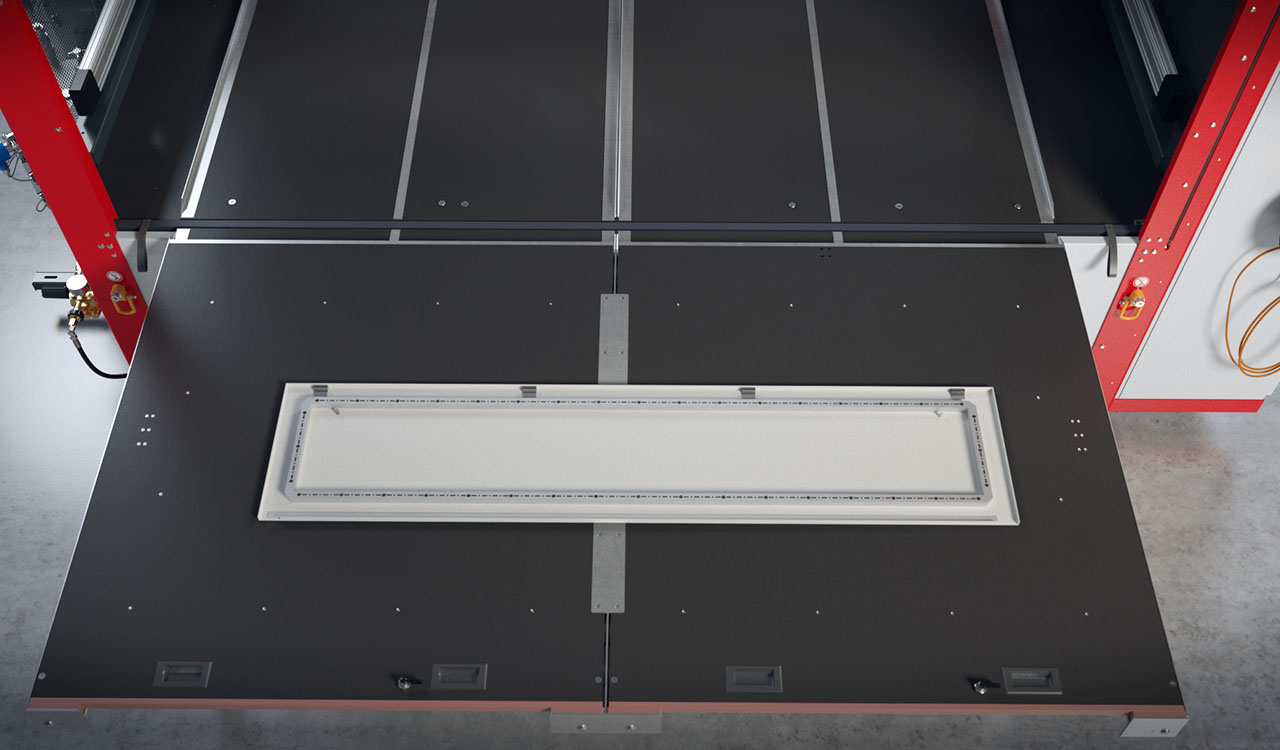

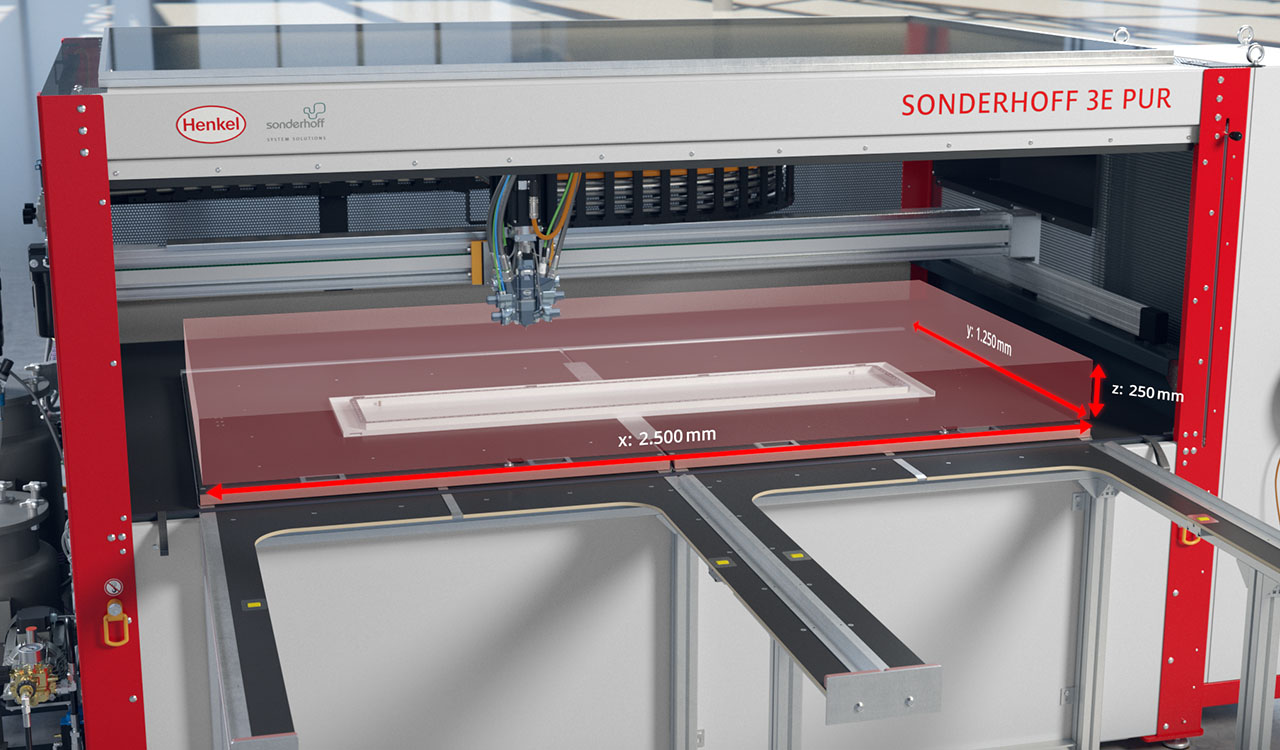

Sliding table with connected mounting plates for oversized parts

The two mounting plates are connected by couplers to form one large sliding table.

Linear robot:

- Max. travel speed: 15 m/min

- Max. acceleration: 2 m/s²

- Repeat accuracy: +/-1 mm

- Travel range x/y/z: 2.500 x 1.250 x 250 mm