FERMAPOR K31

Tailor-made chemistry for growing requirements.

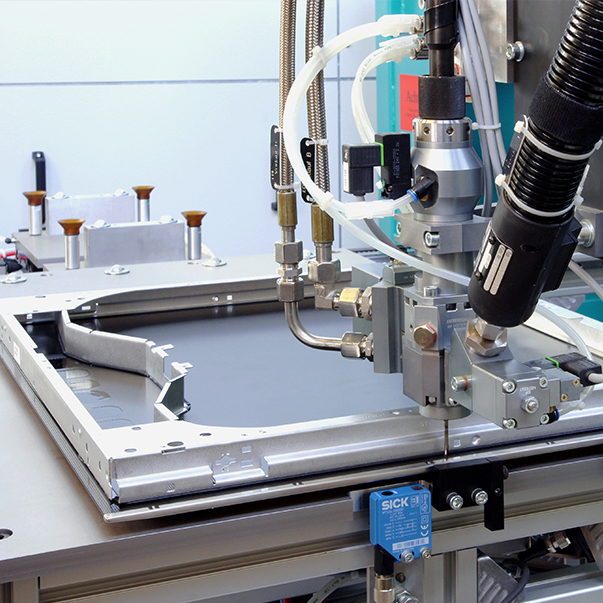

FERMAPOR K31 is the two-component polyurethane system to produce soft elastic foam gaskets, which are foamed directly onto the part using FIPFG technology (Formed-In-Place-Foam-Gasket).

They are directly foamed onto the part with the aid of mixing and dispensing systems and FIPFG sealing technology (Formed-In-Place Foam Gasket).

Chemical reaction

The system consists of a polyurethane-based resin (A-component) and MDI isocyanate hardener (B-component), which are mixed with each other in a predetermined mixing ratio. After chemical reaction of the two material components, it foams up on the part and a soft foam gasket is formed after a few minutes.

After curing at room temperature, the foam gasket is tack-free and can be installed into mating components. According to experience the seal function is achieved with a compression of approx. 30– 60% of the cured foam gasket. The flow behavior, reactivity, degree of hardness and color of the material formulations can be adjusted as required.

Henkel can draw on the variety of more than 1,000 applicationspecific formulations of the FERMAPOR K31 product family.

Broad range of properties

Mixed-cell FERMAPOR K31 polyurethane foam seals have a broad profile of properties, combining the positive sealing qualities of closed-cell systems, e.g. low water absorption, with the low construction forces of open-cell systems. Polyurethane foam seals are used mostly in a temperature range from -40 °C to about +80 °C.

Numerous product properties in the FERMAPOR K31 family

Depending on customer requirements, FERMAPOR K31 can be customized according to various specifications. For this, many different FERMAPOR K31 recipes are available.

| Physical and chemical Properties | ||

|---|---|---|

| Property | FERMAPOR K31 | |

| Appearance | Black or grey, other colors on request | |

| Hardness | From 15 Shore 00 to 40 Shore A achievable | |

| Compression load deflection | 5 kPa to 200 kPa (at 25 % compression) | |

| Density | From 0.1 g/cm³ to 0.6 g/cm³ | |

| Temperature resistance | From – 40 °C to + 80 °C (temporary up to + 160 °C) | |

| Tensile strength | Up to 2 MPa [N/cm²] | |

| Elongation at break | Up to 400 % | |

| Resetting ability | Greater than 97 % (depending on test conditions) | |

| Water absorption | From 3,5 %, hydrophobic versions available, depending on test conditions | |

| Flame retardancy | Up to UL-94 V-2 possible | |

| Optional features |

E.g. sliding properties, low fogging, suitable for food packaging, protection class up to IP68 or NEMA 12 (achievable with suitable component design) | |

Reliability through FIPFG dispensing technology

The FERMAPOR K31 sealing foams can be efficiently and accurately applied on to parts from the most varied industry sectors using the FIPFG (Formed-In-Place Foam Gasket) technology. Depending on the viscosity needed, these sealing foams are either freely applied as a liquid material into a groove or as a highly viscous material to a 2D or 3D part surface.

Only the exact interaction of possible setting parameters of the mixing and dosing machine and the selected FERMAPOR K31 material system enables a reliable sealing against moisture, dust and other environmental influences together with the overall construction of the industrial component.

FERMAPOR K31 – the reaction process

FERMAPOR K31 sealing foams consist of a liquid to pasty A-component (polyol) and a hardener, the B-component (MDI isocyanate). The chemical reaction of FERMAPOR K31 sealing foams is initiated by mixing the A- and B-components. The applied compound foams up to a uniform gasket under room temperature conditions.

| FERMAPOR – the foaming process | |

|---|---|

| Pot life | The time span from the mixing of the A- and B-components to the beginning of the foaming time (approx. 15 – 60 seconds). It is also referred to a processability time or service life. |

| Foaming-up time | The time span in which the FERMAPOR K31 foam system expands to form a seal body (after approx. 30 – 180 seconds). |

| Tack-free time: | The time from which the sealant surface of FERMAPOR K31 foam systems can be touched without causing damage (after approx. 2 – 20 minutes). |

| Assembly time: | The chemical reaction has progressed so far that the FERMAPOR K31 foam systems can bear loads or the foamed components can be assembled (after approx. 20 minutes – 12 hours). |

THE FERMAPOR K31 RANGE SELECTION

The FERMAPOR K31 pallet offers effective seal protection for a wide range of application areas and requirements. In the table you will find a selection of foam sealing systems for various industries, from lighting to switch cabinet, and automotive industry to filters, packaging, and household appliances.

| FERMAPOR K31 A-component |

Application area | Viscosity mPas |

Hardness Shore 00 |

Density g/cm3 |

Other properties |

|---|---|---|---|---|---|

| A-9675-5-VP | Lighting | 1,300 - 1,900 | 20-50 | 0,13-0,24 | UL-50 listed, suitable for moisture-proof luminaires, soft |

| A-9675-2-VP | Lighting | 1,000 - 2,500 | 35 - 75 | 0,25 - 0,50 | UL-50 listed, suitable for moisture-proof luminaires |

| A-3505-1 | Lighting | 2,000 - 3,800 | 30 - 40 | 0,22 - 0,28 | Product for moisture-proof luminaires, especially self-levelling |

| A-4525-1-B-UL | Enclosures | 25,000 - 33,000 | 40 - 50 | 018 - 0,24 | UL-50 listed and good adhesion on lacquer |

| A-9021-2-VP1 | Enclosures | 37,000 - 52,000 | 37 - 52 | 0,25 - 0,35 | UL-50 listed |

| A-45C2-1-UL-FR | Enclosures | 120,000 - 150,000 | 43 - 53 | 0,23 - 0,29 | UL 94 V-2, UL-50 listed |

| A-6045-3-B-UL | Enclosures | 60,000 - 70,000 | 50 - 65 | 0,29 - 0,35 | UL-50 listed, hydrophobic, very good resetting ability (DVR), good adhesion on lacquer |

| A-4545-1 | Enclosures | 45,000 - 55,000 | 40 - 50 | 0,27 - 0,36 | High mechanic strength, low friction, optimized against shear stress |

| A-4530-3-B | Enclosures | 33,000 - 40,000 | 32 - 42 | 0,19 - 0,23 | UL-50 listed, very good resetting ability (DVR), good adhesion on powder coating, fast assembly |

| A-6060-1-B | Enclosures | 55,000 - 65,000 | 50 - 60 | 0,23 - 0,29 | UL-50 listed, hydrophobic, very good resetting ability (DVR), good adhesion on powder coating, fast assembly |

| A-9025-2-VP2 | Enclosures | 35,000 - 50,000 | 28 - 42 | 0,15 - 0,30 | Extremely soft, UL-50 listed, good adhesion on lacquer |

| A-6045-2-B-MX | Filters | 50,000 - 65,000 | 50 - 60 | 0,24 - 0,30 | Microbial inert adjustable, suitable for ventilation systems |

| A-5065-1-G-MX | Filters | 60,000 - 70,000 | 45 - 55 | 0,21 - 0,29 | Microbial inert adjustable |

| A-9308-5-VP5-F | Filters | 130,000 - 200,000 | 38 - 62 | 0,18 - 0,27 | For 3D applications, microbial inert adjustable, suitable for ventilation systems |

| A.3030-1-MX | Filters | 28,000 - 38,000 | 20 - 30 | 0,17 - 0,23 | Extremely soft, microbial inert adjustable, suitable for ventilation systems |

| A-9808 | Filters | 1,000 - 2,000 | 35-65 | 0,17 - 0,35 | For very small groove applications (2 mm) |

| A-6501-3 | Automotive | 900 - 1,500 | 56 - 66 | 0,34 - 0,40 | High tightness, hydrophobic, very good resetting ability (DVR) |

| A-3565-2 | Automotive | 60,000 - 75,000 | 30 - 45 | 0,13 - 0,16 | Extremely soft, low assembly forces |

| A-9308-5-VP5 | Automotive | 120,000 - 160,000 | 35 - 55 | 0,18 - 0,40 | Very high mechanic strength, hydrophobic, for 3D applications |

| A-7060-5-B | Automotive | 55,000 - 70,000 | 55 - 65 | 0,30 - 0,36 | Sealing of E-Mobility batteries, fast assembly |

| A-5555-1 | Automotive | 50,000 - 65,000 | 50 - 60 | 0,24 - 0,30 | High tightness, hydrophobic, very good resetting ability (DVR) |

| A-9199-29-VP3 | Automotive | 45,000 - 60,000 | 20 - 45 | 0,17 - 0,30 | High tightness, low assembly forces and high mechanic strength |

| A-9308-5-VP4 | Automotive | 90,000 - 150,000 | 25 - 50 | 0,15 - 0,27 | Very high mechanic strength, for 3D applications |

| A-9675-11 | Automotive | 1,000 - 1,500 | 28 - 48 | 0,16 - 0,22 | Hydrophobic, suitable for 2D groove applications, low dens |

| A-45C0-1-G-LE | Automotive | 90,000 - 130,000 | 40-50 | 0,18 - 0,24 | Low emissions, meets Daimler DBL5452 and BMW TL 8 350 151_6 design 11 |

| A-6501-4-N | Packaging | 1,000 - 1,700 | 62 - 72 | 0,40 - 0,48 | Very elastic, for high tightness requirements, good resetting ability (DVR) |

| A-9843-8-VP3H | Packaging | 9,000 - 16,000 | 60 - 75 | 0,31 - 0,37 | Good price-performance ratio, good resetting ability (DVR) |

| A-9762-1 | Packaging | 6,000 - 9,000 | 65 - 75 | 0,33 - 0,40 | Approval for food packaging (EU) |

| A-6505-1-N-FD | Packaging | 5,000 - 7,500 | 73 - 83 | 0,24 - 0,30 | Approval for food packaging (EU and FDA) |

| A-9370-VP5 | Appliances | 58,000 - 80,000 | 10 - 30 | 0,18 - 0,26 | Hyper soft for ceramic stovetops |

10 good reasons for FERMAPOR K31 polyurethane foam seal systems

- … is ideally suited for sealing industrial components in practically all shapes and geometries.

- … often achieves particularly good adhesion onto the component through the chemical reaction of

the two material components on the substrate. - … has excellent long-term behavior and shows almost 100% resetting ability even after years of

continuous use. - … is tack-free at room temperature in 2– 20 minutes. A furnace can significantly shorten the reaction

time, but it is not always necessary. - … offers special quick-reacting fast-cure recipes that are tack-free within 120 seconds for higher

production cycle times. - … easily compensates for large component tolerances.

- … forms a cross-linked structure after the reaction, which is extremely resistant to influences

such as moisture, dust and temperature. - … produces foam gaskets with extreme softness.

- … is processed with mixing and dosing systems for two components and can be easily and quickly

changed over to other components, that need to be sealed at any time. - … can be processed profitably even in small production runs.