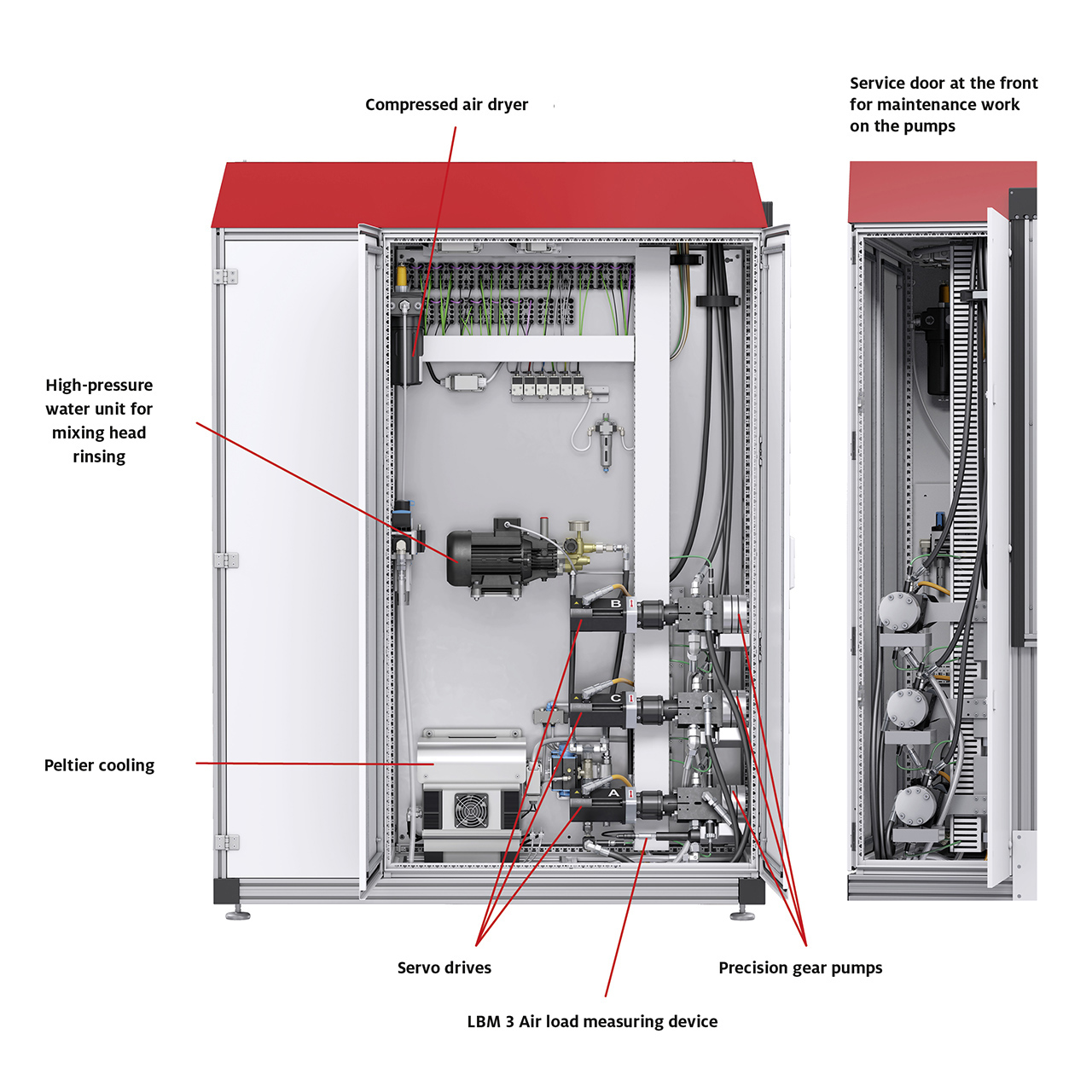

Dosing Machine Cabinet

The dosing machine cabinet is a compact, self-contained unit that contains all the components essential for the dosing process: the precision gear pumps with servo drive for dosing the material components, the high-pressure water unit for rinsing the mixing head, the Peltier cooling unit for temperature control of the mixing head and the recirculation hoses, as well as the LBM 3 air load measuring unit and the compressed air dryer.

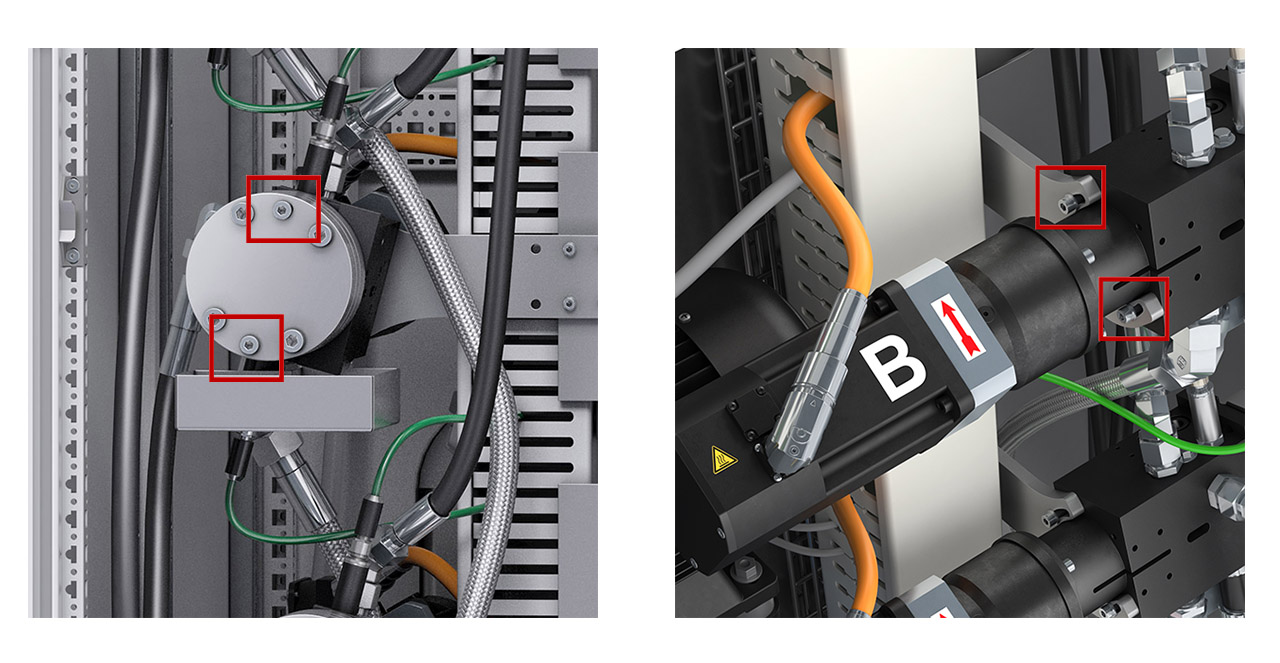

Only 2 screws need to be loosened to replace the pumps and drive train. Direct access for pump head removal is available through the side service door.

In order to remove the pump, only 2 screws need to be loosened. In order to remove the pump including the drive train, only 2 screws need to be loosened.

GENERAL

- Chassis: modular hybrid structure, painted in RAL 7035

- Pressure control for adjusting the recirculation pressure

- Pressure monitoring of the components, optional digital component pressure display for air loading control

- LBM 3 measuring and control unit for air loading

- Mixing ratio: from 100 : 1 to 1 : 100, continuously adjustable

- Application rate: from 0.2 to 100.0 g/s, other application rates on request

- Viscosity processing range: from 50 to 2,000,000 mPas, other viscosities on request

- Material supply monitoring for component pumps

- Compressed air dryer

- Rinsing and filling shot container

DRIVE TECHNOLOGY

Speed-controlled servo gearmotor with speed display and adjustment on the display

| Pumps | Mixing head | |

| Driving power | 1.01 kW | 1.01 kW |

| Driving speeds | 1 - 400 rpm | 1 - 6,000 rpm |

PRECISION GEAR PUMPS (OPTIONALLY)

- For FIPFG sealing foam, size: 0.05 / 0.10 / 0.30 / 0.40 / 0.75 / 3.0 / 12.0 ccm/rev.

- For potting / adhesive applications, size: 0.05 / 0.10 / 0.30 / 0.60 / 1.20 / 3.0 / 6.0 / 10.0 ccm/rev.

- Special pumps on request

HOSE PACKAGE

- Length according to customer requirement with all electrical and pneumatic connections

- A component: Fabric-reinforced polyester high-pressure hose

- B component: Steel-reinforced Teflon high-pressure hose

PNEUMATICS

- Pneumatic system with filter pressure reducer, maintenance unit with pressure monitoring and valve cluster for controlling the pneumatic consumers

CONNECTED LOADS

- Compressed air connection value: approx. 150 l/min at 6 –7 bar

- Water connection value: approx. 13 l/min with at least 4 bar pneumatic consumers

DIMENSIONS

- Dosing machine cabinet: B x H x D 1,210 x 2,000 x 510 mm (without frame, feet or carrying eyes), approx. 300 kg