Mobile Panel and Operating Panel

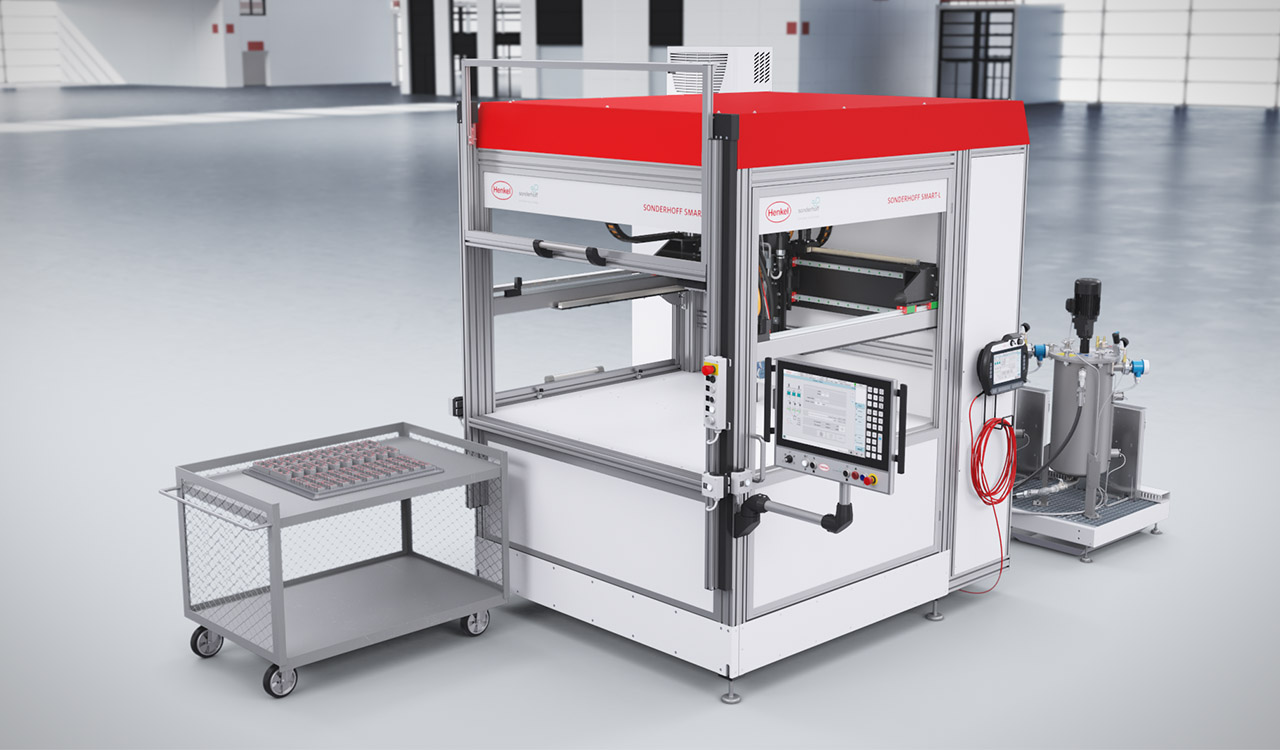

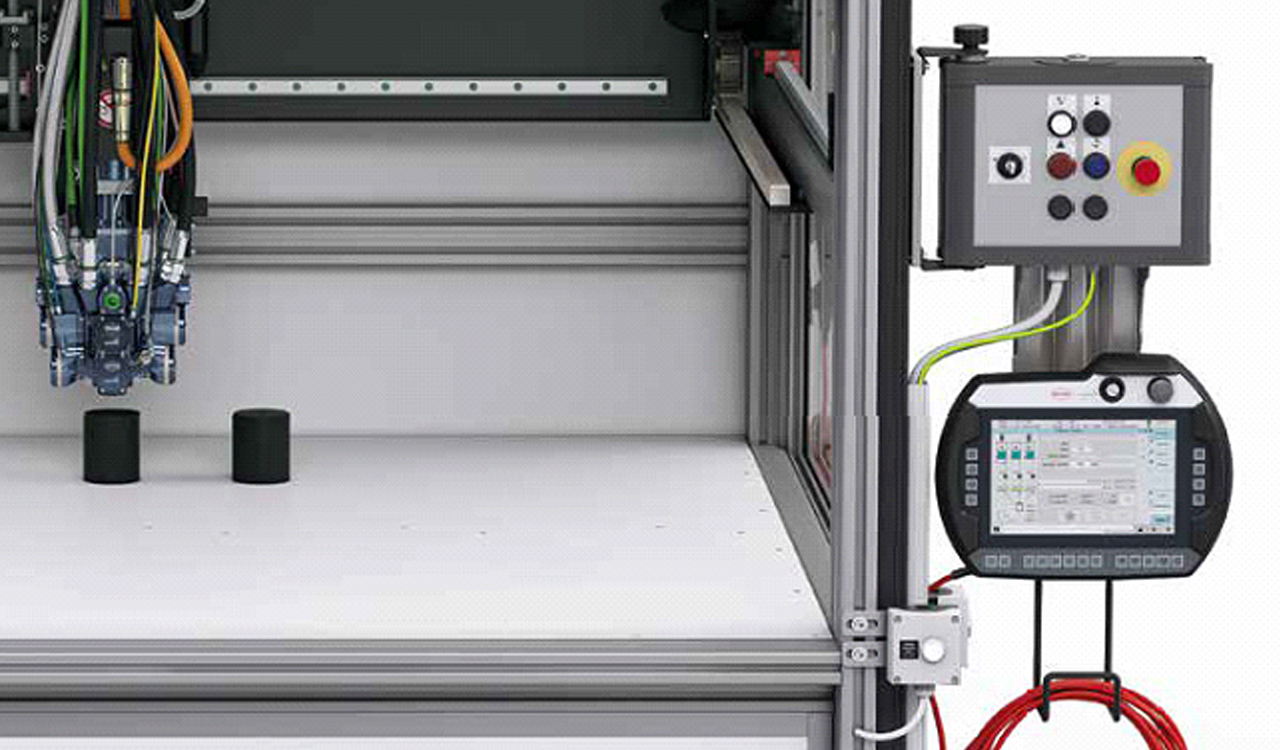

The dosing cells of the SONDERHOFF SMART-L and SMART-M series are designed in such a way that the operator can easily and safely carry out a wide variety of tasks. It is operated as standard via the easy-to-use, multifunctional mobile panel MP 2 (WXGA TFT) with a 10.1-inch touchscreen - a significant simplification when programming the contours of components. The CONTROL 2 multi-touch operating panel with the 21.5-inch user interface is optionally available.

The fully automatic production process of the machine is ensured by presetting and controlling all machine and process parameters. In addition, the sensors installed in the dosing machine continuously deliver measurement data on the influencing factors of the production process, which can be evaluated prognostically and readjusted proactively. And the automatic logging of all systems, material and process data ensures that the previous production process can be traced at all times.

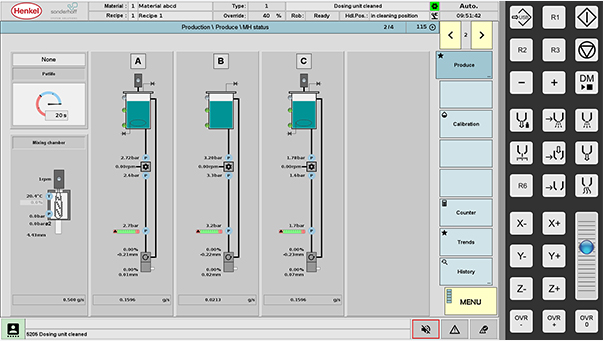

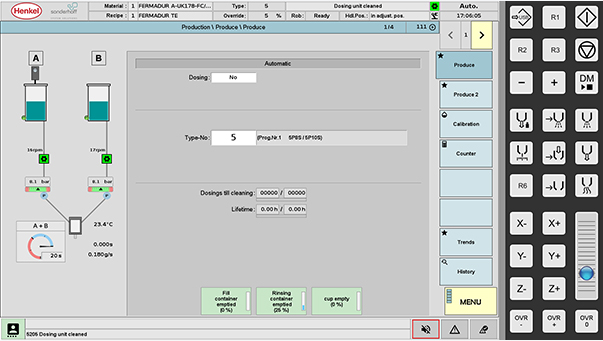

Visualization

The visualization of the data recorded by sensors provides ongoing information about the performance level of the dosing cell and the process status of processing according to the previously defined dosing program.

Universally understandable symbols on the user interface of the mobile panel make the menu navigation language-independent. Colored graphics and the bundling of functions in the operating menu help to evaluate the displayed information of the measurement data more easily and to get a better overview overall. The machine operator can thus concentrate on the core function of operation and compliance with the important machine parameters. This ensures trouble-free production and high product quality.

First column: Reactivity of the material (pot life in s) for active material components as well as detailed information on the mixing chamber and stirrer

Columns 2-4: Overview of the three material components, representation of level in the pressure vessel, line pressure before the pump, pump speed, line pressure after the pump, component pressure at the valve, recirculation control value in %, recirculation valve offset in mm, recirculation status, dosing control value in %, dosing valve offset in mm, current component dosage (g/s)

Shows the active material components, the tank level, the pump speed, the line pressure after the pump, the mixing head temperature, the dosing time (s), the dosing rate (g/s) and the reactivity of the material (pot life in s)

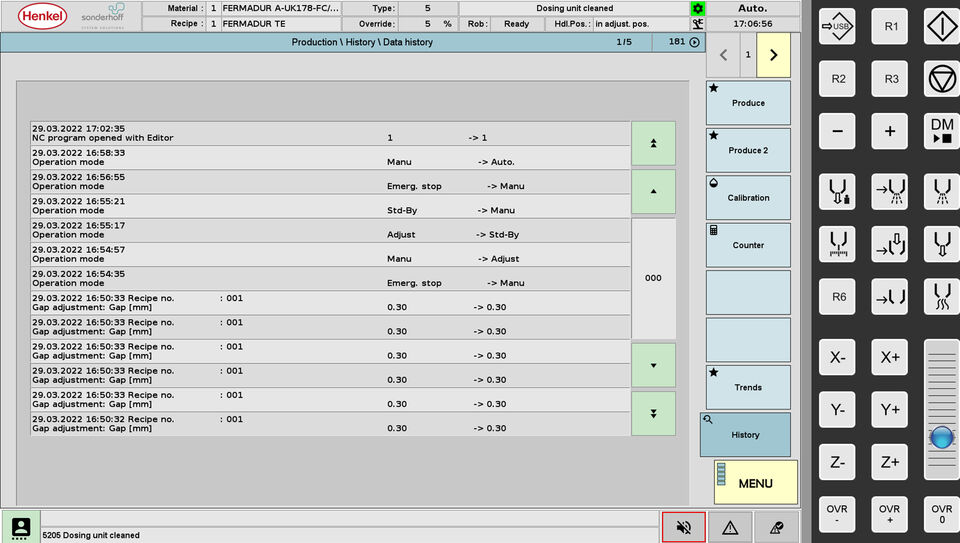

Data history:

Display of date, time, change information old value and changed new value.

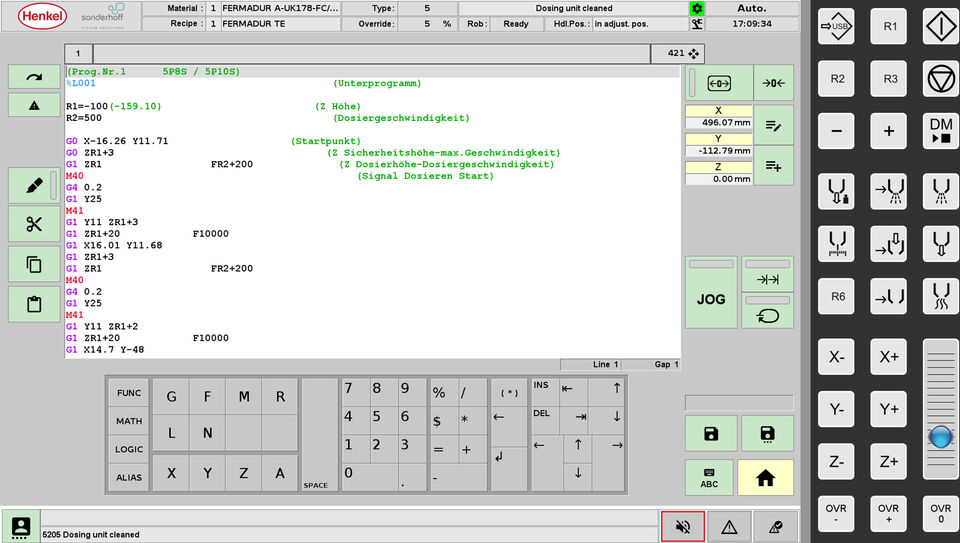

Editor:

NC program is created via the keyboard on the touch screen or via an external USB keyboard

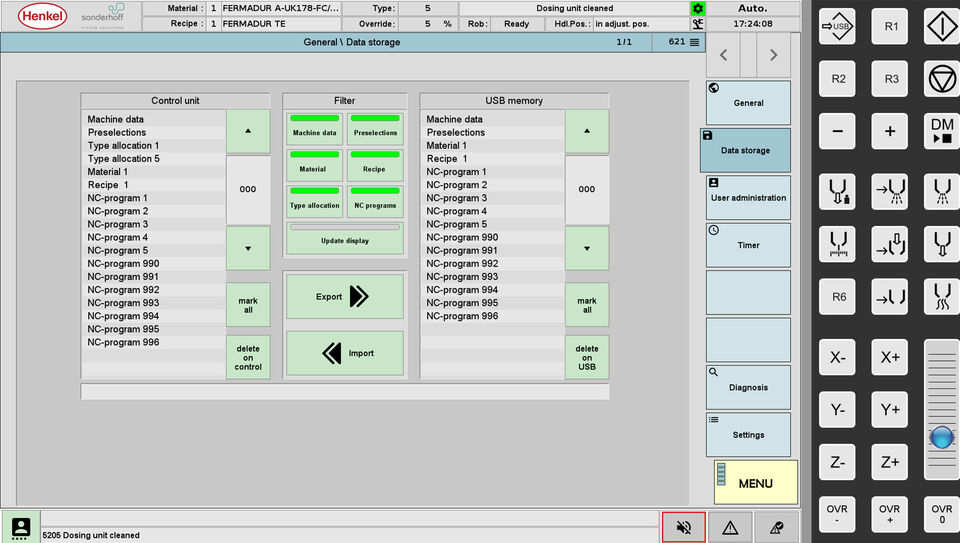

Data backup:

Permits the selective selection of machine data, presettings, type assignments, materials, recipes and NC programs for backup

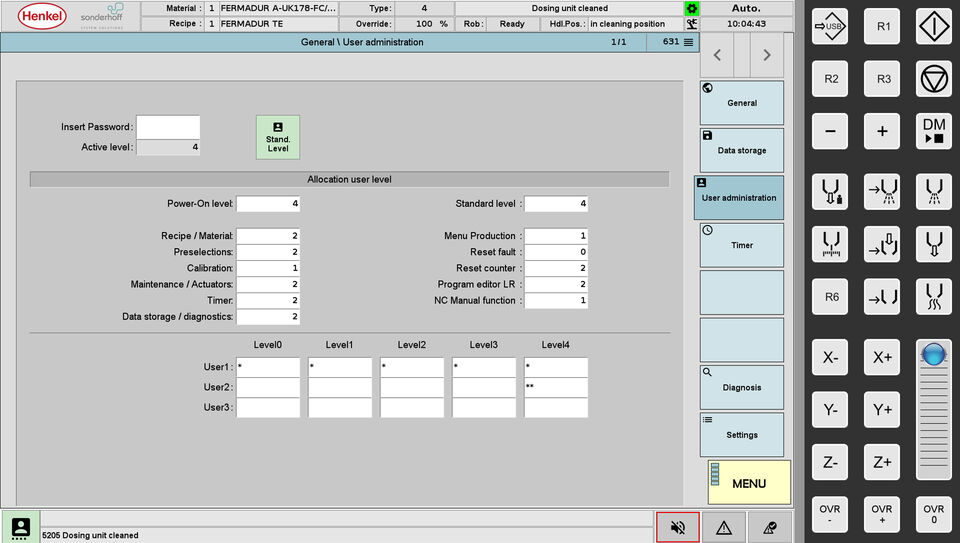

Password:

User management for three users with the option of configuring differentiated access via password levels (0-4).

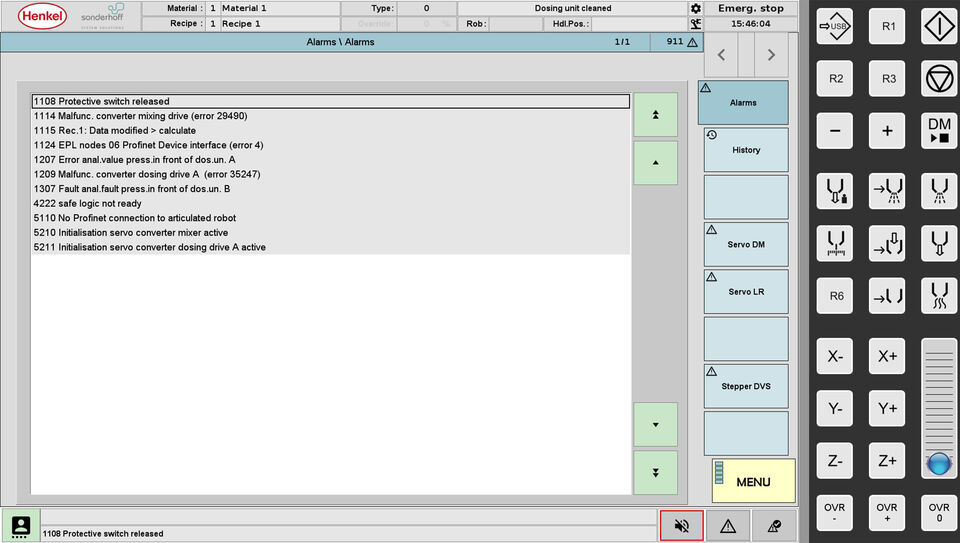

Alarms:

Displays current alarm messages with alarm code and plain text.

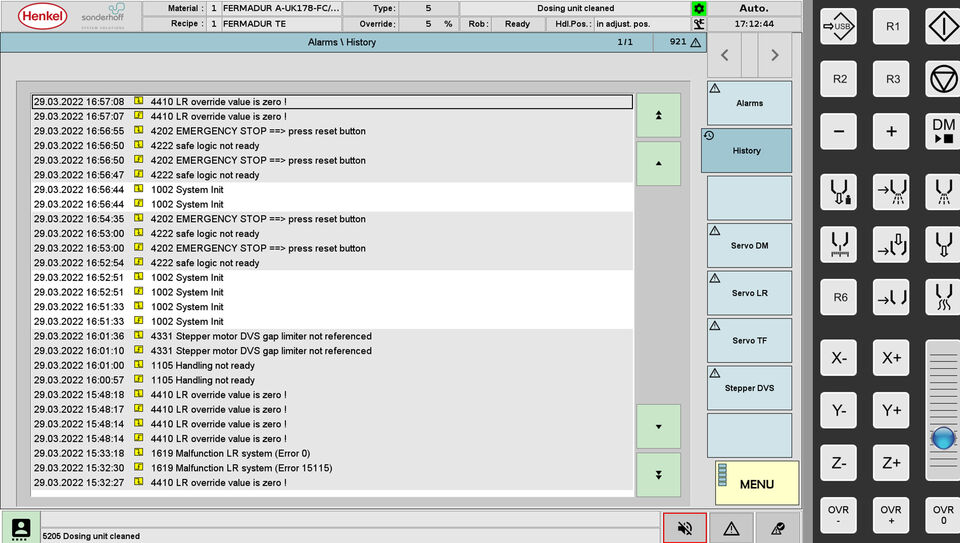

Alarms History:

Displays past alarm messages with date, time, alarm code and plain text, and alarm reset status.