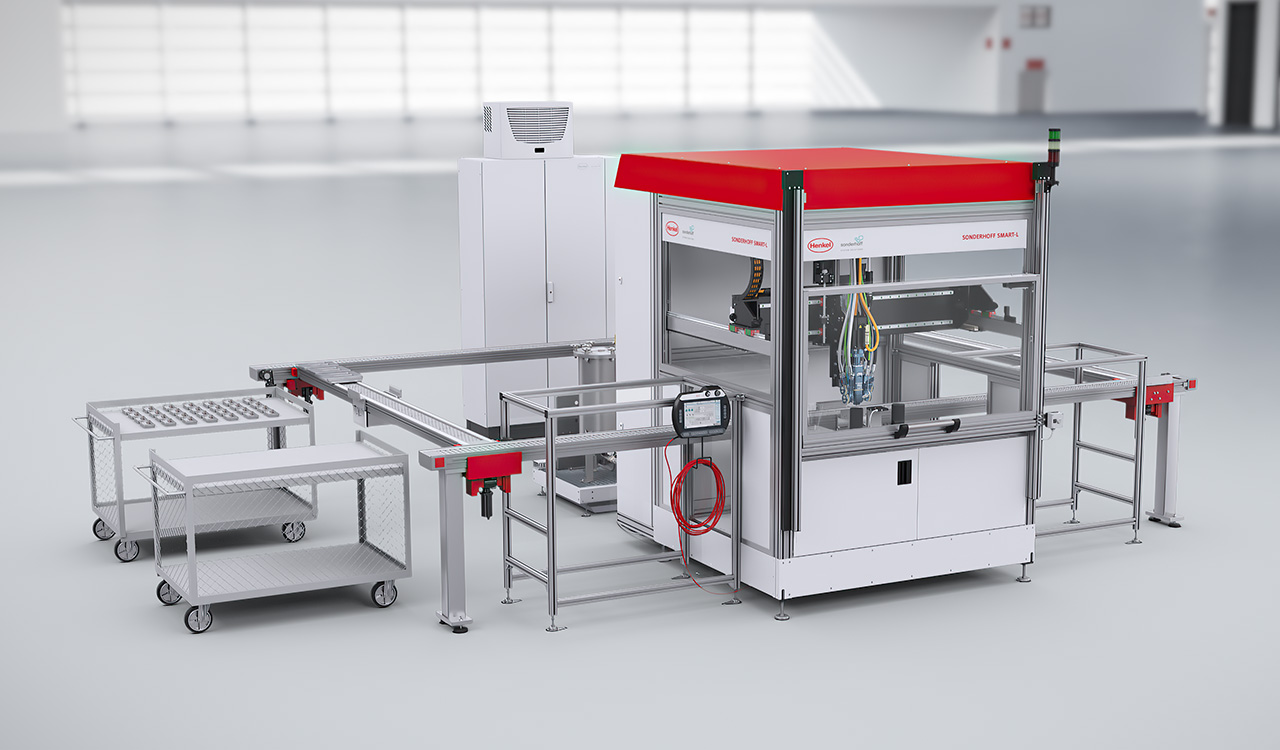

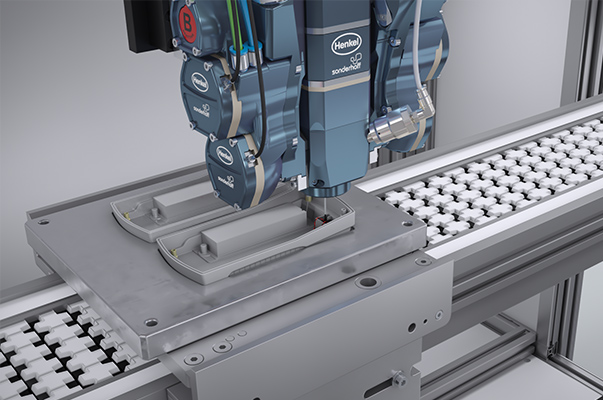

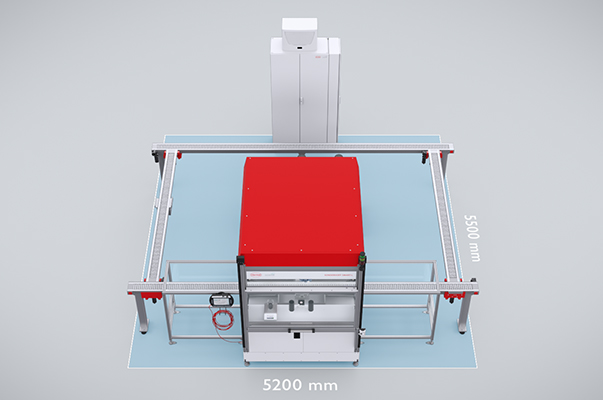

SONDERHOFF SMART-L dosing cells with conveyor belt system

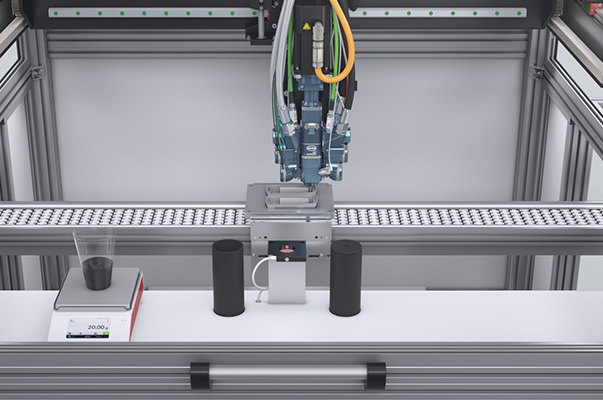

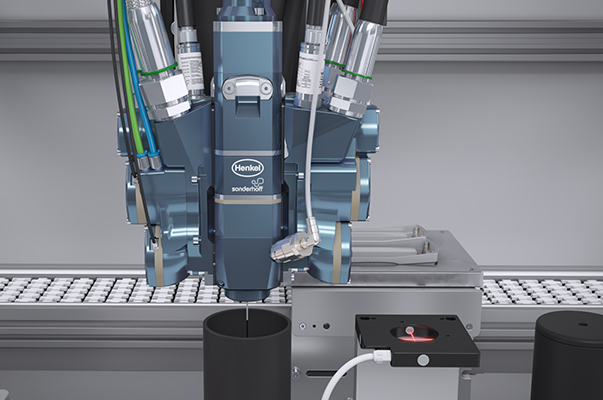

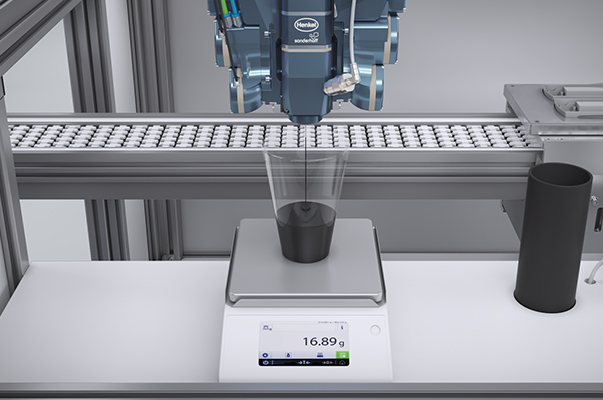

In the case of the SONDERHOFF SMART-L dosing cell, equipped with a lifting door on the front, the components can optionally be fed in for the dosing job via a conveyor belt running through the cell.

The circulating conveyor belt, as in this configuration, is also used for clocking out and as the first curing section.

Animation of SONDERHOFF SMART-L dosing cells with conveyor belt system

Please see our animation of the new SONDERHOFF SMART-L dosing cell with conveyor belt, the dosing cell with the highest process stability for automated foam sealing, bonding and potting.