SONDERHOFF SMART-L dosing cells with shuttle/sliding table

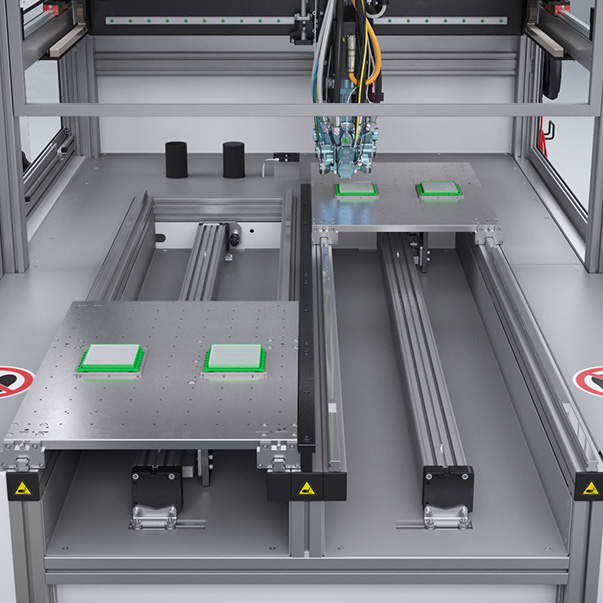

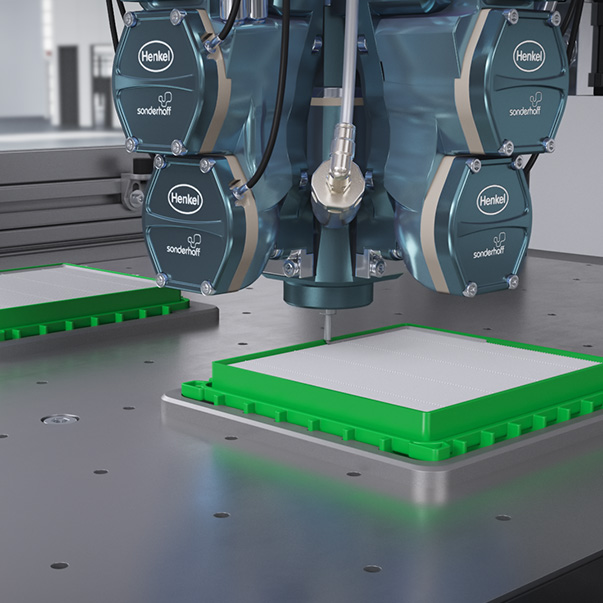

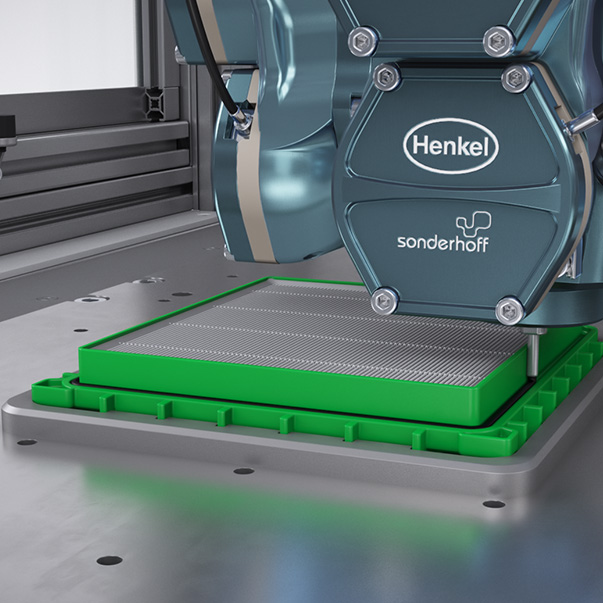

The component assembly of the SONDERHOFF SMART-L dosing cell can also be done in a user-friendly manner via a shuttle/sliding table. With this solution, the machine operator loads the two mounting plates alternately with the components.

The aluminum mounting plates are prepared with a drilling pattern for fastening the workpieces or, if required, with workpiece holders. For the dosing job, the receiving plates move alternately in continuous pendulum operation on one level into the working area of the cell.

Animation of SONDERHOFF SMART-L dosing cells with shuttle/sliding table

Please take a look at our animation of the new SONDERHOFF SMART-L dosing cell with shuttle/sliding table, the dosing cell with the highest process stability for automated sealing foams, bonding and potting.

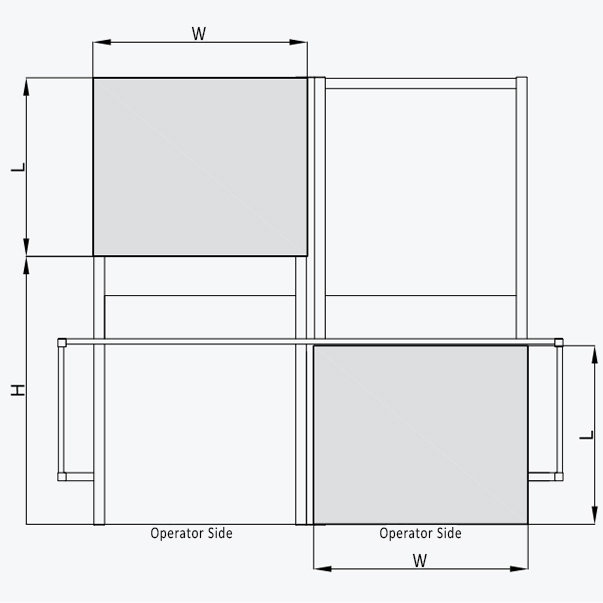

DIMENSIONS WORK SURFACE SLIDING TABLE |

DIMENSIONS

|

||||

|---|---|---|---|---|---|

| Width (W) | Length (L) | Stroke (H) | Working height (AH) | X-Axis | Y-Axis |

|

550 mm |

800 mm (746 mm usable workspace) |

1,500 mm | 950 mm | 1,000 mm | 800 mm |

Special sizes can be produced on request.