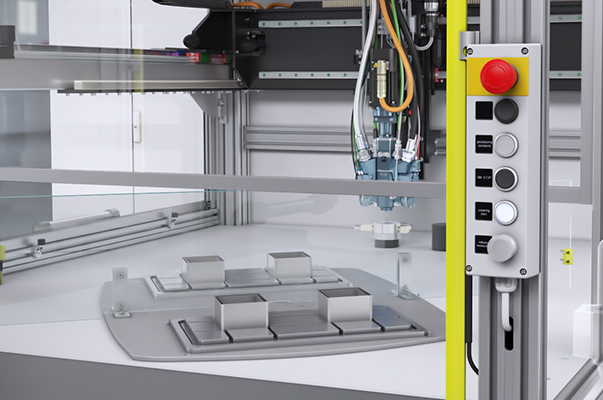

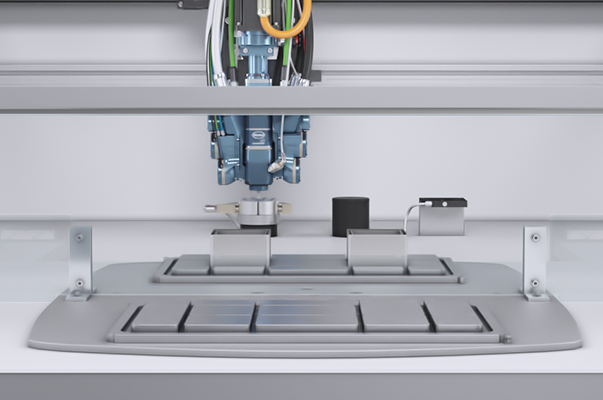

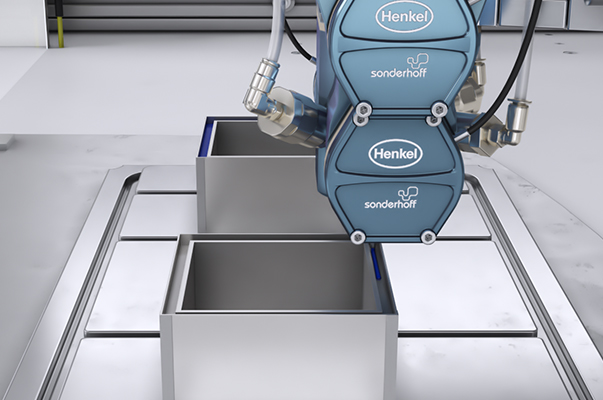

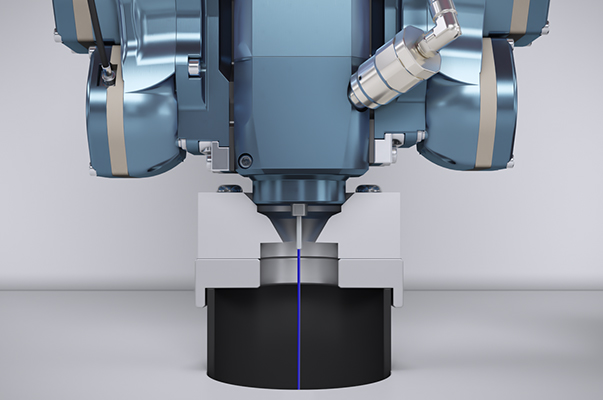

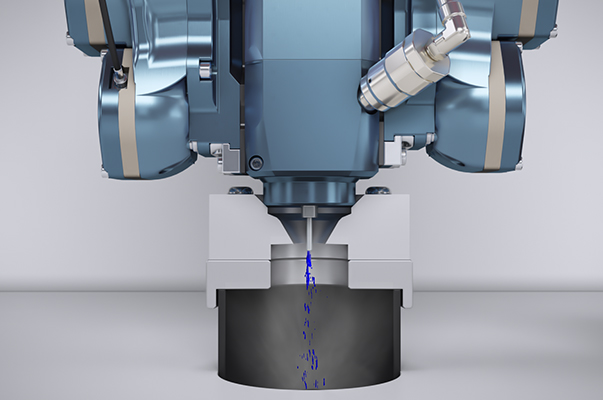

SONDERHOFF SMART-M dosing cells with rotary indexing table

The component assembly of the SONDERHOFF SMART-M dosing cell for sealing foams, bonding or potting can also be done user-friendly via a rotary indexing table.

This has e.g. a 180° division for the loading and working position (other divisions possible), with a rotation cycle of approx. 1.5 sec. The insertion area is protected by a light grid for component assembly.

Animation of SONDERHOFF SMART-M dosing cells with rotary indexing table

Please see our animation of the new SONDERHOFF SMART-M with rotary indexing table, the dosing cell with the highest process stability for automated sealing foams, bonding and potting.