Perfect sealing of HEPA filters for air-conditioning units

The job of the interior filters of air-conditioning units is to remove harmful materials such as soot and dust, even in extreme weather conditions, to remove surrounding influences and supply pure air to the interior.

The increasing pollution of the air with fine particulate matter has led to the formulation of a new international testing norm ISO 16890. It replaces filter classification according to the previous norm EN 779, whereby the efficiency of a filter was determined unrealistically as an average, and only for particle sized of 0.4 µm.

With the new method for the assessment of air filters a paradigm-shift has taken place: In future the filtration grades (min. 50%) will be determined with regard to fine particle classes PM1 (< 1 µm), PM2.5 (< 2.5 µm) and PM10 (< 10 µm). These classes are also adopted by the World Health Organisation (WHO) and by environment authorities.

Filter media perform the specific functions of filter appliances. The filter medium takes on the physical task of separating gases and solids. Depending on the area of use, they are exposed to variations in temperature, neutral, dry, damp or chemically aggressive gases, fine or coarse dusts.

Filter media are sensitive structures, produced from fine natural or synthetic fibres. The finer the fibre, the greater the specific surface area and the better the filtration effect, as a rule. The smallest particles (< 5 µm) are extracted from the air by electrostatic attraction to the fibres. With this technique, high-quality particle filters can filter practically 100% of the dust and particles from the air.

But even the finest fine particle filters fail to stop unfiltered air from infiltrating the interior through a leaky filter frame. This is where the polyurethane-based sealing foams and potting products SONDERHOFF FERMAPOR K31 and SONDERHOFF FERMADUR offer an absolutely solid filter seal.

Perfect intake through optimal filter gluing

Every ordinary vacuum cleaner is equipped with a fan which produces a negative pressure. On the suction side of the cleaner is a suction inlet. The intake air is led directly into the air-permeable bag. This filters the air and collects the dust at the same time. Usually, hoover bags are made of multi-layered paper filters (2-5 layer of varying grain) or non-woven fabric.

Normally, after passing the bag, the air enters a second filter that extracts even finer dust. In front of the engine sits a coarse filter, protecting the engine and fan, in case the bag is ripped by the intake of sharp objects. In the outgoing air zone there is usually a microfilter, which also contains the fine abraded coal-dust from the carbon brushes of the motor.

Seals and Adhesives by Henkel ensure that the filters do what they promise: Clean air

Bacteria and mould have no chance

Special additives in the material formulation of SONDERHOFF FERMAPOR K31 antimicrobial foam sealings effectively protect the sealings of climate-control components for air distribution such as ventilation grilles, air filters, nebulisers and access locks against attack by harmful micro-organisms. The testing results of the Berlin air hygiene institute (ILH Berlin) as regards DIN EN ISO 846 (determination of the effect of micro-organisms on plastics) confirm that SONDERHOFF sealants are not a source of nutrition for micro-organisms.

With these products, Henkel can fulfil the hygiene requirements of the producers of air-conditioning and climate control technologies for such appliances in accordance with VDI 6022 for the sealing and bonding of air filters. They always seal the filter emplacement reliably, for the optimal ventilation of residential, factory and office spaces with clean air and a healthy climate for the well-being of their human inhabitants.

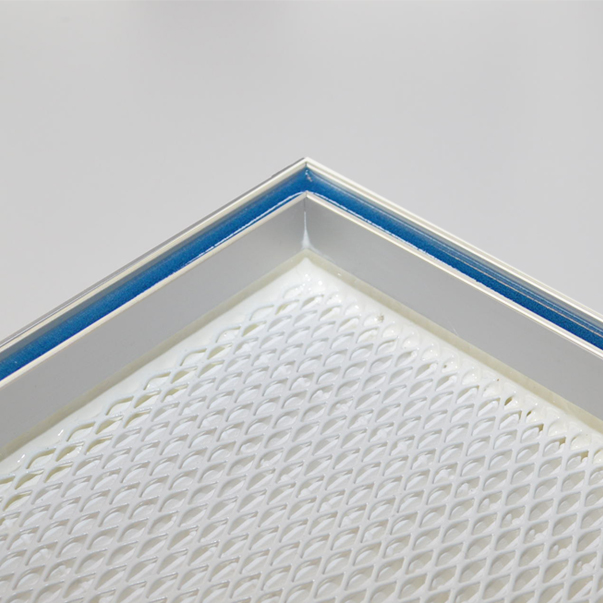

Gel seals for clean rooms – ultra-tight, glass clear and bubble-free

The most modern production processes in e.g. the pharmaceutical and microelectronics industries demand a high measure of air purity. The air filters required for clean rooms, from HEPA (High Efficiency Particulate Air) to Super-ULPA (Ultra Low Penetration Air) filters, must not only be finished to the highest quality standards, but also be built in place in a leak-free mount.

This is ensured by SONDERHOFF FERMADUR polyurethane or SONDERHOFF FERMASIL silicone seals for highly efficient clean room filters. With the precise sealing technology of the SONDERHOFF mixing and dosing systems, the gel seals are applied bubble-free and glass-clear in the groove of the filter frame. They are also available in low Shore hardness grades. Through the gel seals’ high ageing resistance, leaks and losses of tension are excluded.