Sonderhoff Services, headquartered in Cologne and since July 2017 part of Henkel AG & Co. KGaA, will be presenting its entire range of contract manufacturing services at the KUTENO Kunststoff-technik Nord supplier trade fair from 7 to 9 May in Rheda-Wiedenbrück (Stand F6 / Hall 2).

As a member of the Henkel Group, customers of Sonderhoff Services benefit from Henkel's extensive product portfolio. The Sonderhoff Services machine park was expanded to include dosing systems suitable for machine processing of Henkel's 1-component adhesives TEROSON® and LOCTITE®. Not only do they ensure precise, contour-accurate dispensing, but the experts at Sonderhoff Services also master complex joining processes with 1-component adhesives.

Sealing, bonding and potting - know-how for the customer

With their decision for contract manufacturing at Sonderhoff Services, customers have access to the entire know-how of the new group of companies and the many years of experience of the process specialists at Sonderhoff Services. They take over the sealing and mould foaming, bonding and casting of components on Sonderhoff Engineering dosing systems for suppliers and OEMs from very different user industries. The contract manufacturer can choose from more than 1000 Sonderhoff material systems based on polyurethane, silicone and PVC for fully automatic, contour-accurate dosing on components. The liquid material flows into each other at the beginning and end of the seal, so that after foaming a "seamless" soft foam seal is formed by a chemical reaction, which hardens at room temperature. By compressing the foam seal, manufacturing tolerances of a component are compensated and well-sealed all around.

The Formed In-Place (FIP) technology used is already the production standard in many industries. "The FIP process is significantly more economical than a manually inserted seal," adds Jörg Dethlefs, project manager in the technical sales department at Sonderhoff Services. The automated application allows higher cycle times to be achieved than with a manual process. And a consistently high process quality avoids rejects, which ultimately leads to significant cost savings with consistently high quality.

At Sonderhoff Services, the material systems and dosing systems are optimally matched to each other. This results in synergy effects that enable Sonderhoff Services to meet different component requirements to a particularly high degree. Depending on the customer's requirements, for example, different curing and tack-free times of the material systems can be set.

Advice and sampling for an individual sealing solution

The contract manufacturer from Cologne is not only an extended workbench for its customers in the event of capacity bottlenecks. In fact, Sonderhoff Services is a reliable production partner to industry for individual, component-specific solutions from a single source. The long reference list of renowned industrial customers of Sonderhoff Services stands for the quality and the confidence of the customers in the efficiency of the contract manufacturer.

Customers often use the know-how of Sonderhoff experts as early as the design phase of the components. The advantages are that the seal seat is designed FIP-compatible and the constructive protection of the seal against external influences is already taken into account in the best possible way in this early phase. For example, the choice of an ideal height-width ratio of the seal, an optimum groove geometry of the component and a suitable material play an important role. "Even the component sample, the prototype, should meet the requirements for the future series part," says Georg Kondziella, Plant Manager at Sonderhoff Services. Cooperation with the customer covers the entire process from component design to series production on a production scale and effective quality control. It includes the sampling of prototypes and pilot series, the actual analysis of the component requirements as well as the technical application consulting, and finally it produces the optimum component solution.

Comprehensive range of services for many industrial sectors

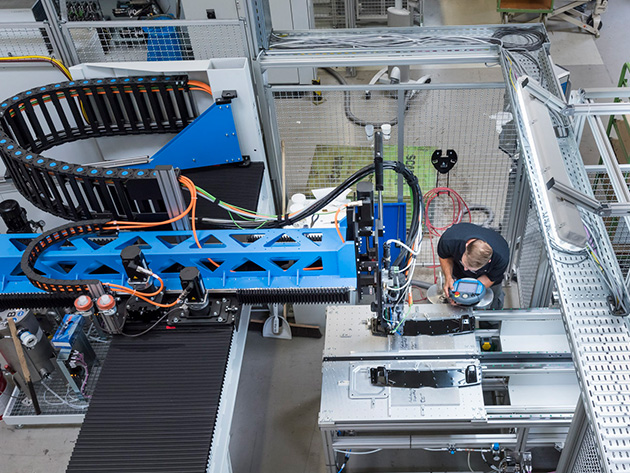

Sonderhoff Services manufactures on a production area of approx. 1,500 m² with state-of-the-art dosing and mixing systems from Sonderhoff Engineering. The parts mainly come from the automotive, lighting, electronics, air-conditioning, filter and household appliance industries.

Different component sizes from small to large series are applied with material on the systems. Mixing heads are available for material dosing from 2 to 100 g/s for larger components such as control cabinet doors and from 0.05 to 2 g/s for very small parts.

Sonderhoff uses CNC-controlled linear robots for the dosing systems, which move the mixing head for the material dosing at different speeds over the component contour. This allows different discharge quantities to be realized. This is a particular advantage when it comes to the automatic material application of large quantities and complex component geometries in series production.

Polyurethane or silicon-based sealing foams from 2D groove applications to highly thixotropic three-dimensional applications are processed, as well as PUR-based encapsulation and adhesive systems. All contract manufacturing processes are fully documented with a certified quality management system for each order and continuously optimized in a continuous improvement process (CIP). This means that Sonderhoff Services leaves nothing to chance. In fact, the contract manufacturers relieve the customer of a part of his responsibility for component quality through their comprehensive range of services, from the machines to the material to safe process automation.