Modular and handy

The modular workstation for processing and dispensing of low to highly viscous 1- and 2-component bonding, sealing and potting materials

The SONDERHOFF DM 90 is a modular dosing machine for semi-automatic and fully automatic processes, that can be customized to specific production and process requirements by considering static or dynamic mixing demands.

It has been specifically developed for demanding applications in a variety of industries. It is ideally suited to:

- Home appliance industry, for example in the production and assembly of ovens, cooktops, refrigerators and washing machines, dryers and dishwashers

- Automotive industry, particularly for e-mobility applications, front lighting systems, exterior components and the vehicle’s electrical and electronic architecture (EE)

- Medical and filter technology: including precise processing of dialyzers, oxygenators and hollow fiber potting components.

This broad range of applications makes the DM 90 a powerful solution for modern manufacturing processes where precision, reliability and flexibility are essential.

Flexible today and tomorrow

The compact and modular design of the DM 90 meets all technical and quality requirements of suppliers – not only for the mentioned applications but also for a wide range of industrial use cases.

Especially in the precise processing and dosing of 2-component materials, the automation of manual processes, and the traceability of process data, the DM 90 demonstrates its strengths. Its modular architecture allows for easy adaptation to changing production needs – both now and in the future.

Guaranteed quality and efficiency

With the launch of the DM 90, we ensure the high quality you expect – while also offering benefits such as reduced material consumption, shorter production times, and increased consistency and reliability in mixing and dosing.

Industry 4.0 features, a global service network, and the option for seamless integration into existing automation lines highlight the DM 90’s future-readiness.

User-Friendly and Space-Saving

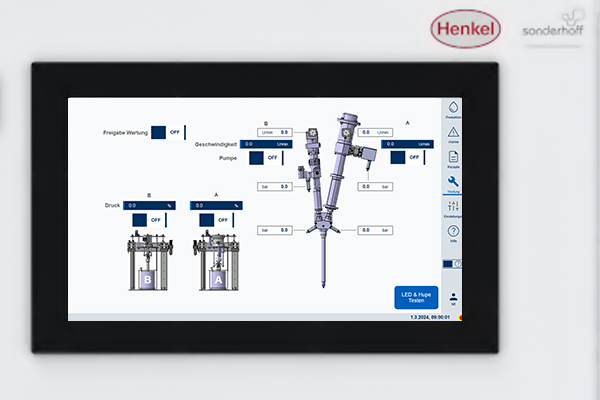

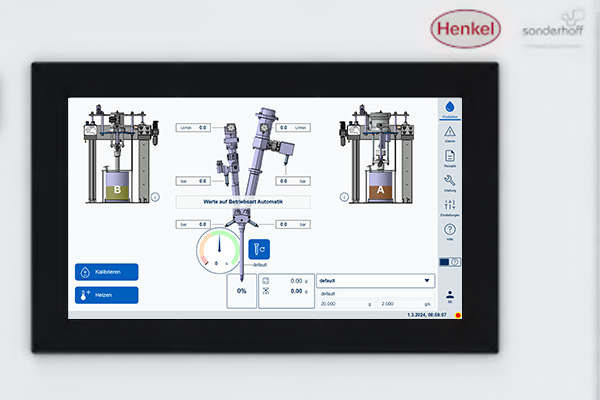

The DM 90 is designed to enable operators to handle a wide range of tasks safely and intuitively – supported by a 15.6“ touchscreen for control and visualization. An integrated process data logging system records ma-terial pressures, pump torque, weighing data, correction factors, and alarm messages. A standout feature is the interactive, menu-guided calibration and dosing process, continuously verified via precision scale weighing.

A machine as flexible as your application

The DM 90 is built on a powerful base machine that we configure precisely to your requirements.

Whether bonding, sealing, or potting, we combine the right modules, processes, and materials to deliver exactly the solution your production needs.

Since every application is unique, the DM 90 is designed to adapt seamlessly to your processes. Its modular architecture allows us to create a mixing and dispensing system that matches your materials, workflows, and quality expectations perfectly.

From the robust base machine and flexibly combinable modules, we create a customized production system.

Every option – from material conditioning to the dispensing head and process control – is selected to ensure the ideal fit for your application.

DM 90 - Overview and special features

Touchscreen

Process data logging

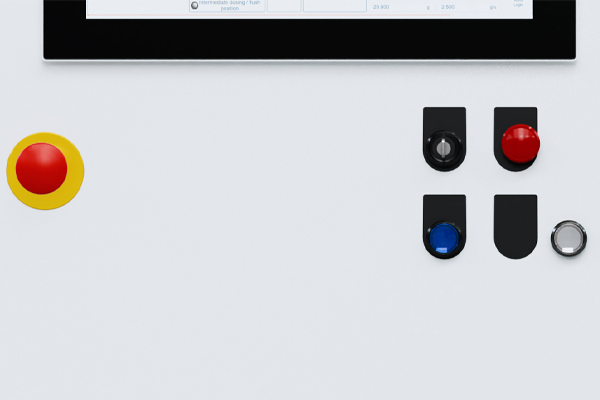

Operating mode control panel

Rollable chassis

Precise dosing pumps

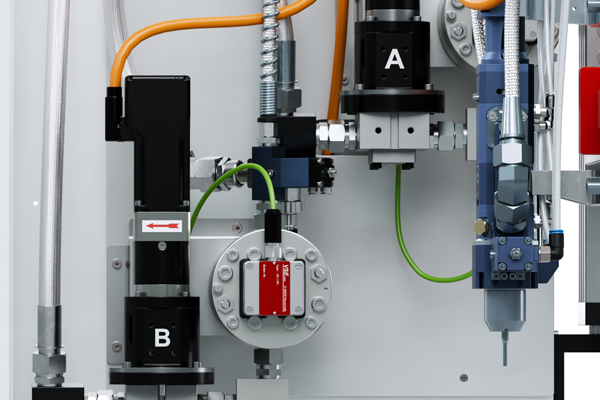

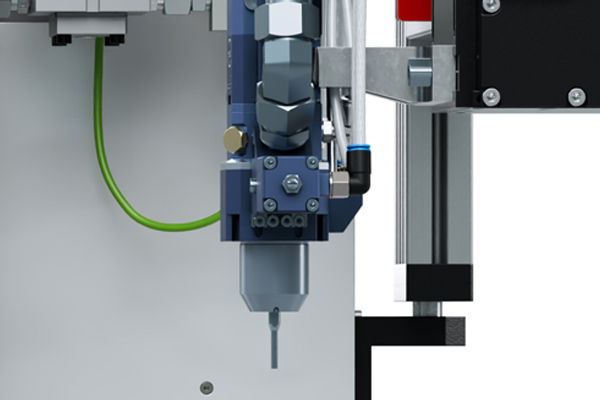

2K precision mixing head with static or dynamic mixing

Integrated precision scale

Touchscreen

Process data logging

Operating mode control panel

Rollable chassis

Precise dosing pumps

2K precision mixing head with static or dynamic mixing

Integrated precision scale

Touchscreen

Visualization and operation via 15.6“ touchscreen with interactive menu- guided calibration and dosing process

Process data logging

of material discharge quantities, mixing ratios, material pressures, pump torques, weighing data, correction factors and alarm data

Operating mode control panel

of material discharge quantities, mixing ratios, material pressures, pump torques, weighing data, correction factors and alarm data

Rollable chassis

Dosing machine mounted on rollable chassis

Precise dosing pumps

Both gear pumps and screw pumps are available for particularly abrasive materials. The pump size is individually adapted to the customer‘s process.

2K precision mixing head with static or dynamic mixing

with servo drives, for discharge rates infinitely variable from 1.0 to 2.5 g/s and mixing ratios from 10:1 to 1 : 1 (depending on pump size and material viscosity)

Integrated precision scale

for permanent weighing check for calibration and dosing