Description of MK 825 PLUS

-

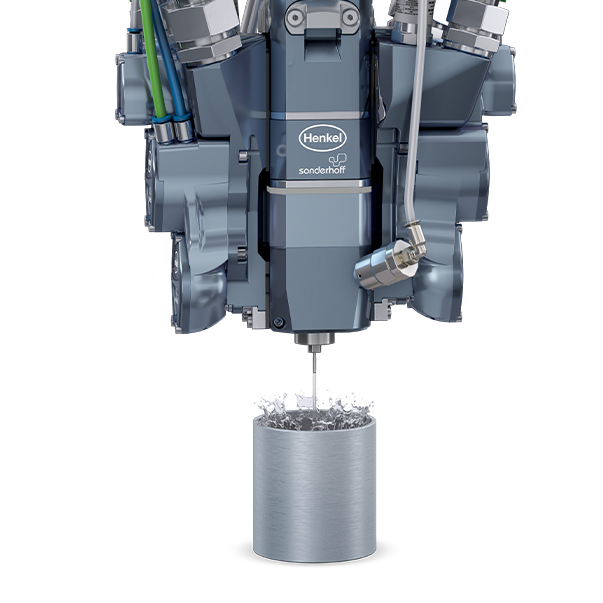

Sensor-controlled 2-component mixing head with high-pressure water rinsing and dynamic mixing of liquid to highly viscous polymeric reaction materials for foam gasketing, bonding and potting processes

-

High-pressure water rinsing for ecological cleaning of the mixing chamber

-

Alternative: rinsing with A-component

-

Servopneumatically and hydromechanically controlled precision valves for precise dosing

-

Can also be equipped with stub lines for bonding or potting applications

-

Weight-reduced construction of a modular design, blue-gray anodized

-

Size-optimized, functional V design to increase the degrees of freedom

-

Robust and maintenance-free design made of high-strength aluminum alloy and chrome steel

-

Direct stack injection of the components

-

Electronically adjustable stirrer speed

-

Special stirrer design enables gentle material mixing

-

Blowing air needle valve for drying the mixing system

-

Low-drip, low-maintenance nozzle shut-off system STOP-DROP DVS 3

-

Simple stroke adjustment by means of an adjusting wheel

-

Material pressure measurement at the dosing valve

-

Mixing chamber temperature sensor

TECHNICAL DATA* |

MK 825 PLUS |

|

Dimensions (H x W x D) 2K mixing head |

248 x 204 x 151 mm |

|

Operating pressure |

up to approx. 20 bar |

|

Discharge rate |

0.2 to 3.0 g/s |

|

Dispense Accuracy |

±1 % |

|

Mixing head weight |

approx. 5.5 kg |

|

Mixing ratio |

continuously adjustable from 10:1 to 1:2 |

|

Selectable mixer speed |

continuously adjustable from 1 - 4,500 rpm |

|

Viscosity processing range |

Material component A: 1,000 – 100,000 mPas (*) |

* Depending on the mixing ratios, material viscosities and the selection of pumps, hoses and mixing elements.