Bonding the worktops of washing machines and clothes dryers

Numerous components in washing machines and clothes dryers are bonded to achieve a high level of tightness, stability, vibration resistance and durability. Bonding is increasingly replacing mechanical connections such as screws or welding – especially for plastic and metal components.

Bonding in washing machines and dryers is technologically demanding, as different substrates and operating conditions have to be taken into account. Modern bonding processes with robot-assisted dispensing technology enable high-quality, durable, tight and vibration-resistant joints.

Leading manufacturers of household appliances have been relying on our dispensing technology and the large selection of innovative adhesives for many years. Optimally coordinated material and dispensing machine systems with CNC-controlled mixing head guidance above the component ensure process-stable and precise material application and efficient bonding of washing machine and dryer components.

The cover plates (worktops) of washing machines and clothes dryers - also known as “top covers” - fulfill important technical, visual and practical functions: They form the top cover of the appliance, protect the internal technology, contribute to noise insulation and serve as a work surface.

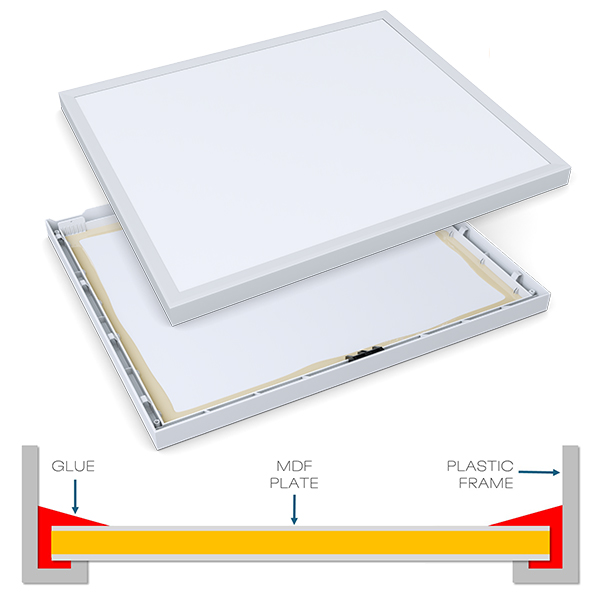

The top cover of washing machines and dryers consists of a plastic frame into which a coated MDF panel is bonded.

The adhesive also fulfills a structural and sealing function to prevent moisture from penetrating.

The 2K adhesive LOCTITE® UK 8445 B1 W/UK 5400 used to bond and seal the MDF panel fills the gap between the frame and the worktop.

This means that also the cross-sectional areas of the MDF board that are not coated are protected from moisture.

Tailor-made adhesive solutions for washing machines and clothes dryers

LOCTITE® UK 8445 B1 W (A-comp.) / LOCTITE® UK 5400 (B-comp.) is a 2-component, solvent-free, polyurethane-based casting compound. By mixing both components in a weight ratio of 100:22, a hard-elastic product is created. After curing, the product shows no measurable change in volume. It is used as a potting and filling compound and as a potting system for fast-setting lid bonding in the manufacture of washing machines, dryers, refrigerators and freezers.

Reference material

| Bonding and sealing the worktop cover of washing machines and dryers |

||

| LOCTITE® UK 8445 B1 W | ||

| LOCTITE® UK 5400 | ||

| Mixing ratio | 100 : 22 | |

| Pot life (A-/B-Komp.) | 70 - 74 sec. | |

|

Final curing time (23°C) |

1 day | |

| Average viscosity (A-comp.) | 8,000 mPas | |

| Density (A-Komp.) | 1.46 - 1.56 g/cm³ | |

| Tensile shear strength (A-/B-comp.) | > 6 mPa | |

| Operating temperature | from -40 to + 80 °C | |

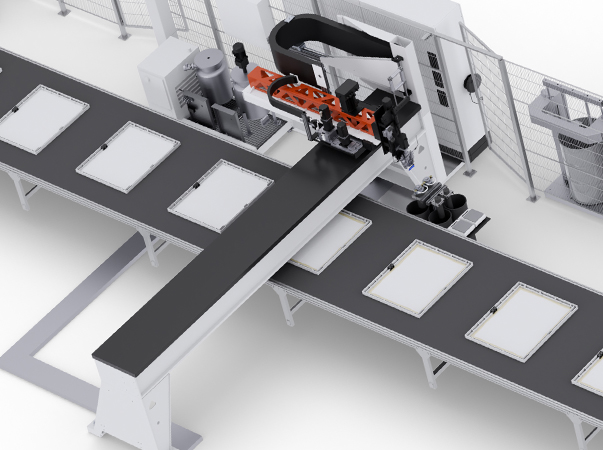

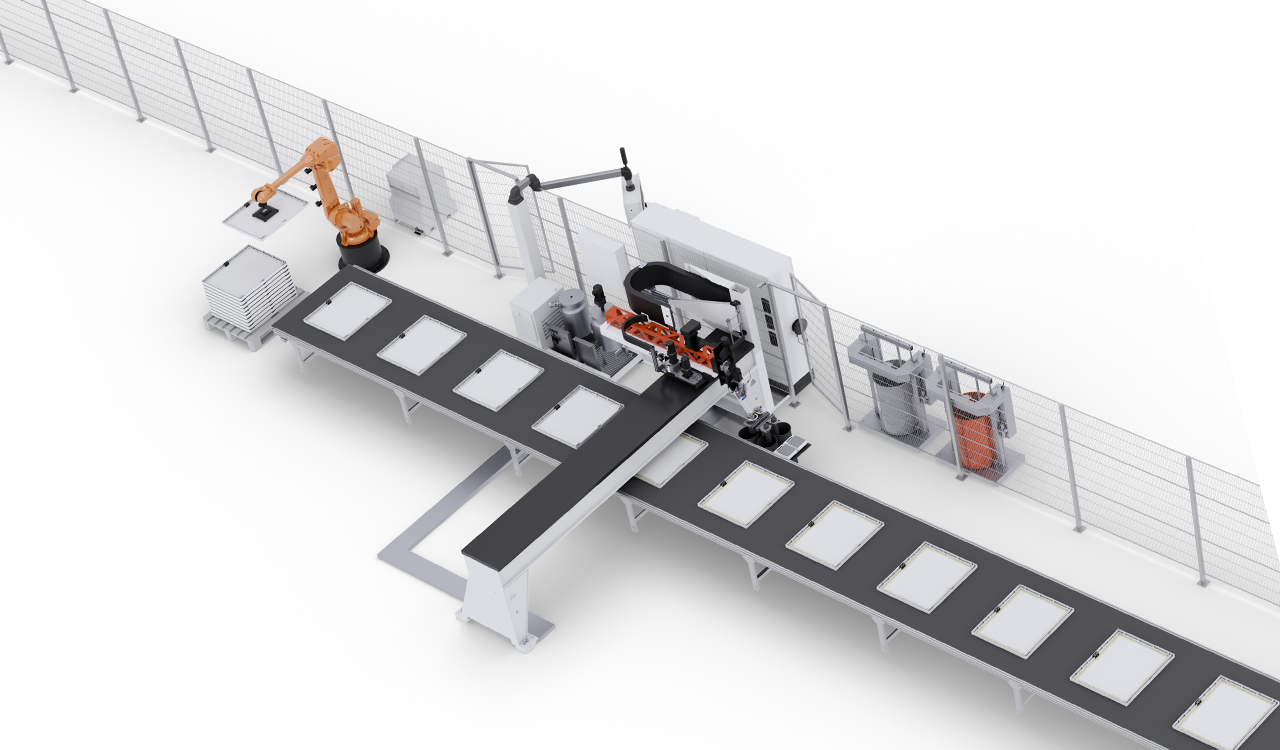

DM502 mixing and dosing system with conveyor belt and 3-axis linear robot for bonding the washing machine cover and 6-axis robot for parts' handling

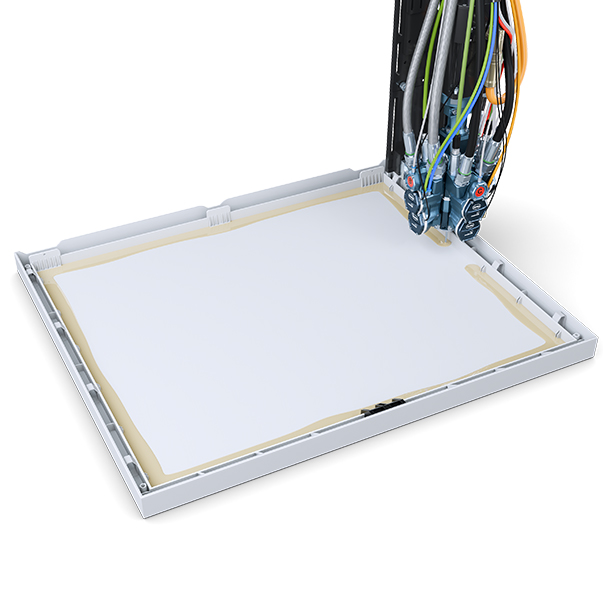

The adhesive is applied to the frame of the washing machine worktop using the DM502 and the MK800 PRO mixing head, which is controlled by the LR-HD 3-axis linear robot or a 6-axis robot.

The material is supplied by the automatic refilling station, which consists of a drum pumping station (FPS) for each of the A and B components.

There are various options for adhesive application, either the DM502 is integrated into a fully automatic production line with a transfer belt for feeding and removing the components to be bonded or as a stand-alone machine with the WT 1-Level shuttle/sliding table.

For this purpose, the washing machine worktop frames are positioned on one level on the WT 1-Level shuttle table and then moved alternately on the two separately movable mounting plates under the mixing head for adhesive application. For this, the MK800 PRO mixing head is guided by the 3-axis linear robot fully automatically and very precisely over the contour of the washing machine worktop.

Alternatively, the DM70 COMPACT mobile dosing machine can also be used for adhesive applications, with which the adhesive is applied to the frame contour for bonding to the washing machine cover panel using a handgun.

The DM70 COMPACT mobile dosing machine for processing one or two components enables the manual application of different materials using a handgun, consisting of either the MK20 or MK50 mixing head. It is a mobile stand-alone system and can be used in your production to save space. Functional design, proven technology and reliable processes guarantee the profitability of your investment.

All machine components are housed on a mobile chassis. The easy accessibility of the machine enables maintenance and servicing work to be carried out quickly and easily.