Bonding the control panels of washing machines and clothes dryers

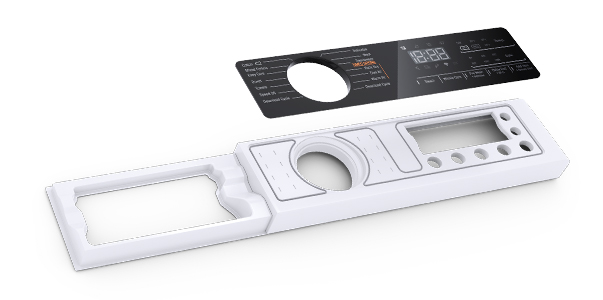

The control panels of washing machines and clothes dryers – also known as front panels – are important components for operating the appliance and integrating the electronics (display, buttons, rotary selector) and combine mechanical stability, visual appeal and electronic functionality.

They essentially consist of a carrier housing made of thermoplastic material, usually ABS or PC-ABS, which is manufactured by injection molding. This carrier forms the basic framework into which the other components are mounted.

A printed circuit board (PCB) is integrated into the panel, on which electronic components such as microswitches, light-emitting diodes (LEDs), touch sensors or displays are located. The connection to the central control unit of the washing machine is usually made via plug contacts or ribbon cables.

Operating elements such as push buttons, rockers or rotary knobs are guided through the panel from the outside and mechanically positioned.

A separate decorative element made of plastic or glass is often used for the visible front surface, which is either printed, painted or bonded with a printed film directly during injection molding using the in-mold labeling (IML) process.

This creates high-quality, scratch-resistant surfaces with symbols, lettering and design features. Depending on the model, a display window made of clear plastic (PMMA or polycarbonate) is integrated into the decorative element of the control panel.

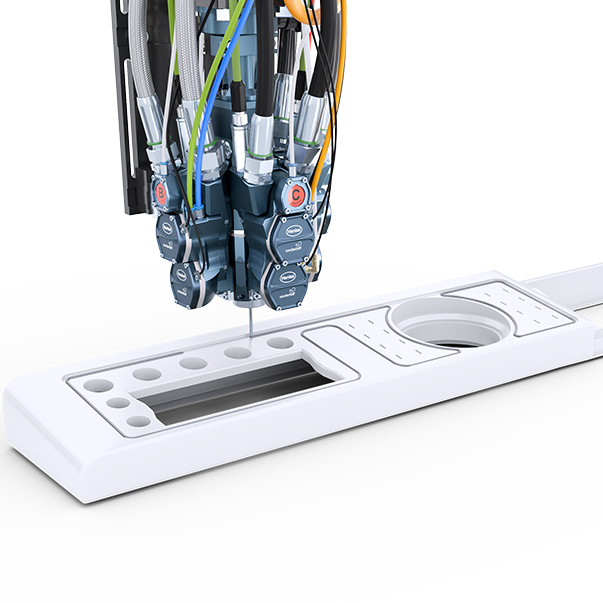

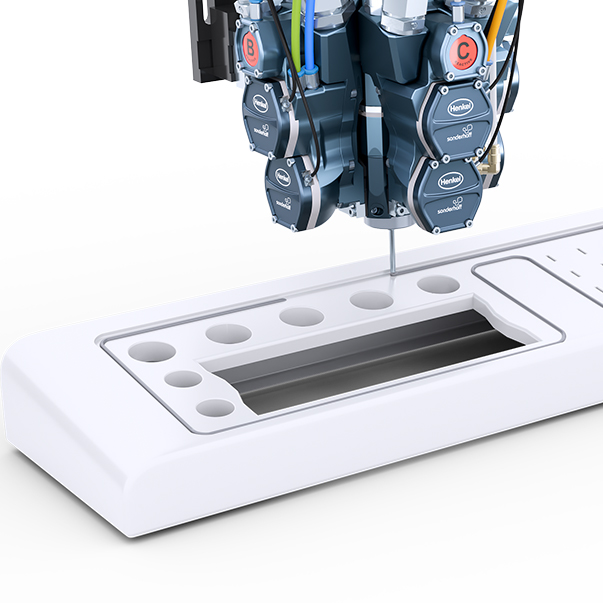

The MK800 of the DM502 mixing and dispensing machine applies the 2K silicone structural adhesive LOCTITE® SI 5610 A/B precisely into the groove contour for bonding the decorative trim with display window to the carrier housing of the control panel.

After the adhesive has been applied, the decorative panel is joined to the carrier housing.

A particular advantage of the 2-component silicone structural adhesive LOCTITE® SI 5610 A/B is that it does not require primer pre-treatment.

The control panels of washing machines and clothes dryers not only meet technical requirements, but also contribute significantly to the user-friendliness and brand image of the appliances

Tailor-made adhesive solutions for washing machines and clothes dryers

The display element is bonded to the carrier housing of the control panels for washing machines and clothes dryers

using the fast-curing 2-component silicone structural adhesive LOCTITE® SI 5610 A/B.

The advantage of this LOCTITE® material is that pre-treatment (e.g. with a primer) for surface adhesion is not necessary.

The dosing application takes place within the pot life of approx. 2 to 3 minutes. Installation can take place approx. 3 minutes after application.

Alternatively, the 2K silicone structural adhesive LOCTITE®

SI 5615 or, for the USA market, LOCTITE® SI 5600 A/B can be used, which are just as fast curing, achieve excellent adhesion to glass, metals and Ceran® and have a temperature resistance of up to 180°C (356°F).

Reference material

| Bonding of control panels |

LOCTITE® SI 5610 A/B |

|

|

Mixing ratio (by weight) |

2 : 1 | |

|

Pot life (A + B mixed) |

≤ 6 min. | |

|

Tack-free time at 23 °C / 50 ± 5 % RH |

2 - 3 min. |

|

|

Curing at ambient temperature |

approx. 30 min. |

|

|

Viscosity A-Component |

approx. 20,000 - 100,000 mPa·s |

|

|

Viscosity B-Component |

approx.10,000 - 80,000 mPa·s |

|

|

Shore-A hardness (ISO 868) |

approx. 30 - 50 |

|

|

Elongation at break (ISO 527-3) Tensile strength (ISO 527-3) |

210 % approx. 1.35 (200 psi) |

|

|

Service temperature |

from -40 to +180 °C (higher short-term) |

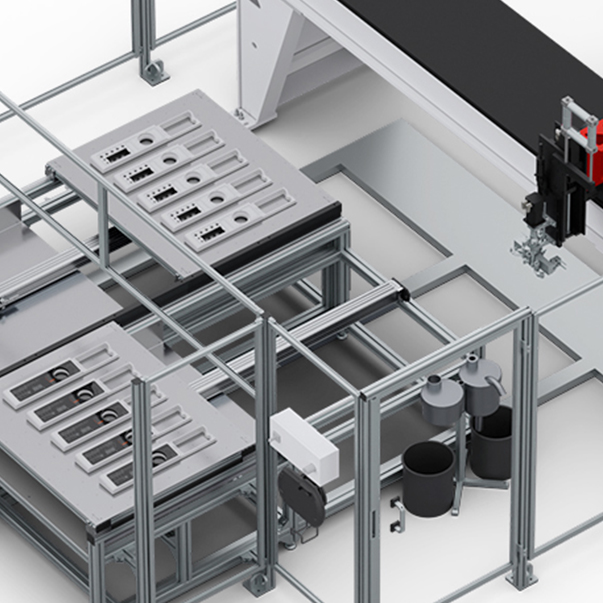

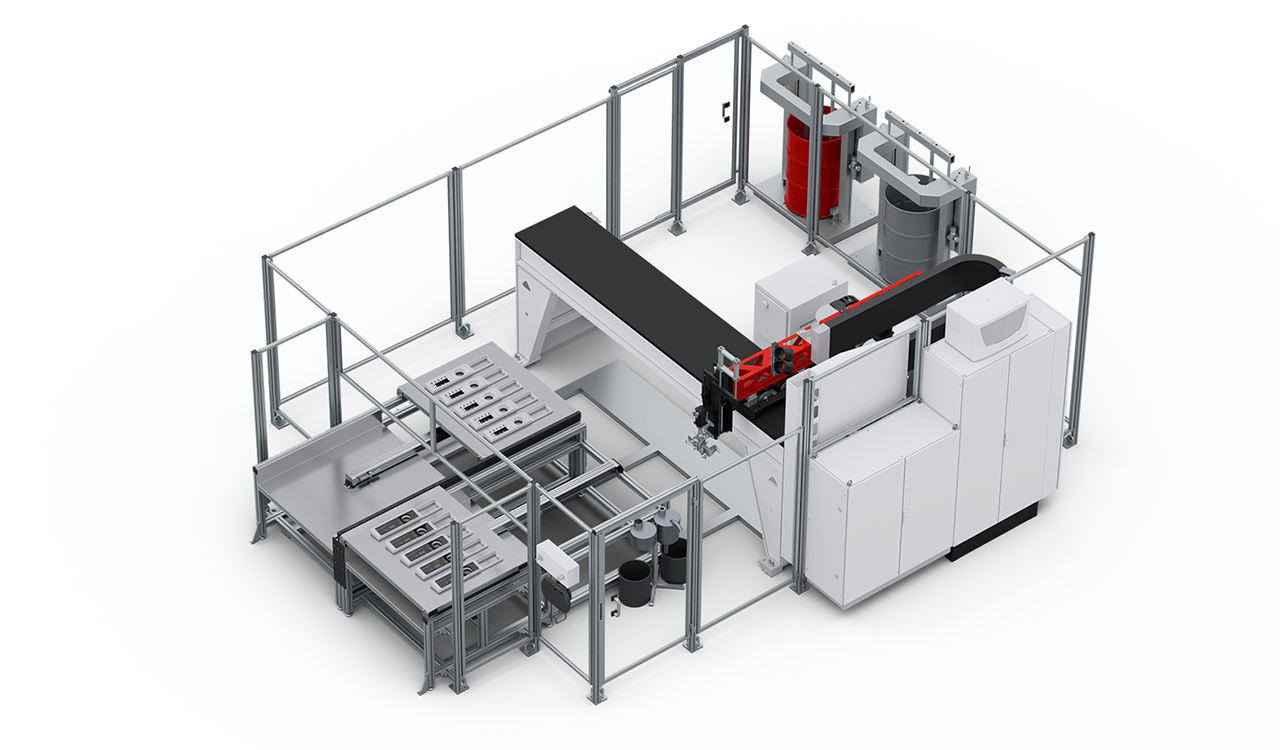

DM502 mixing and dosing system with 3-axis linear robot and WT 1-Level shuttle table for bonding control panels for washing machines and clothes dryers

The adhesive for bonding the display element to the carrier housing of the control panel is applied using the DM502 mixing and dosing machine and the WT 1-Level shuttle table.

The MK800 PRO mixing head, which is controlled by the LR-HD 3-axis linear robot or a 6-axis robot, applies the adhesive to the pre-programmed contour fully automatically with high dosing accuracy.

For this purpose, the carrier housings are positioned on the WT 1-Level shuttle/sliding table in one plane on the two separately movable mounting plates, which then move alternately under the mixing head for the adhesive application. The MK800 PRO mixing head is moved very precisely over the contour of the carrier housing by the 3-axis linear robot. In the next processing step, the decorative display element is joined to the carrier housing.

The material is supplied by the automatic refilling station, which consists of a drum pumping station (FPS) for each of the A and B components.

Our mixing and dosing machines can be operated easily and intuitively without the need for extensive training. Thanks to the automatic recording of the dosing program data, all process data can be traced and evaluated by the operating personnel via the CONTROL 2 operating panel while production is running.

With all solutions, our main focus is on highly reliable system technology, minimized maintenance times and consistent dosing quality. As process experts, we support you with customized advice for the automation of your production processes.