Bonding the porthole glass element for washing machines

For many years now, leading manufacturers of household appliances have been relying on our system solution consisting of innovative adhesives with different property profiles and the mixing and dosing systems optimally adapted to them for the precise and efficient bonding of components for washing machines and clothes dryers.

The fast-curing 2K silicone structural adhesive LOCTITE® SI 5610 A/B is used to bond the porthole glass element for washing machines to a mounting frame.

This has good adhesion to glass and plastic, good temperature and moisture resistance and is resistant to cleaning agents.

A particular advantage of the 2K silicone structural adhesive LOCTITE® SI 5610 A/B is that it does not require primer pre-treatment.

After bonding, another plastic frame is screwed onto the previous one so that the glass lies between the 2 plastic frames.

Tailor-made adhesive solutions for washing machines and clothes dryers

The fast-curing 2K silicone structural adhesive LOCTITE® SI 5610 A/B is used for bonding the porthole/door glazing of washing machines to a mounting frame.

The adhesive is applied to the plastic mounting frame using the DM502 mixing and dispensing machine, which is integrated into an automation line.

The MK800 PRO mixing head for dispensing is controlled by either the LR-HD 3-axis linear robot or a 6-axis robot. The material is supplied by the automatic refilling station, which consists of a drum pumping station (FPS) for each of the A and B components.

LOCTITE® SI 5610 A/B is dispensed within the pot life of approx. 2 to 3 minutes. Assembly can take place approx. 3 minutes after application.

Reference material

| Bonding of porthole / door glazing |

LOCTITE® SI 5610 A/B |

|

|

Mixing ratio (by weight) |

2 : 1 | |

| Pot life (A + B mixed) | ≤ 6 min. | |

| Tack-free time at 23 °C / 50 ± 5 % RH |

2 - 3 min. |

|

| Curing at ambient temperature |

approx. 30 min. |

|

|

Viscosity A-Component |

approx. 20,000 - 100,000 mPa·s |

|

|

Viscosity B-Component |

approx. 10,000 - 80,000 mPa·s |

|

|

Shore-A hardness (ISO 868) |

approx. 30 - 50 |

|

|

Elongation at break (ISO 527-3) Tensile strength (ISO 527-3) |

210 % ca. 1.35 (200 psi) |

|

|

Service temperature |

from -40 to +180 °C (higher short-term) |

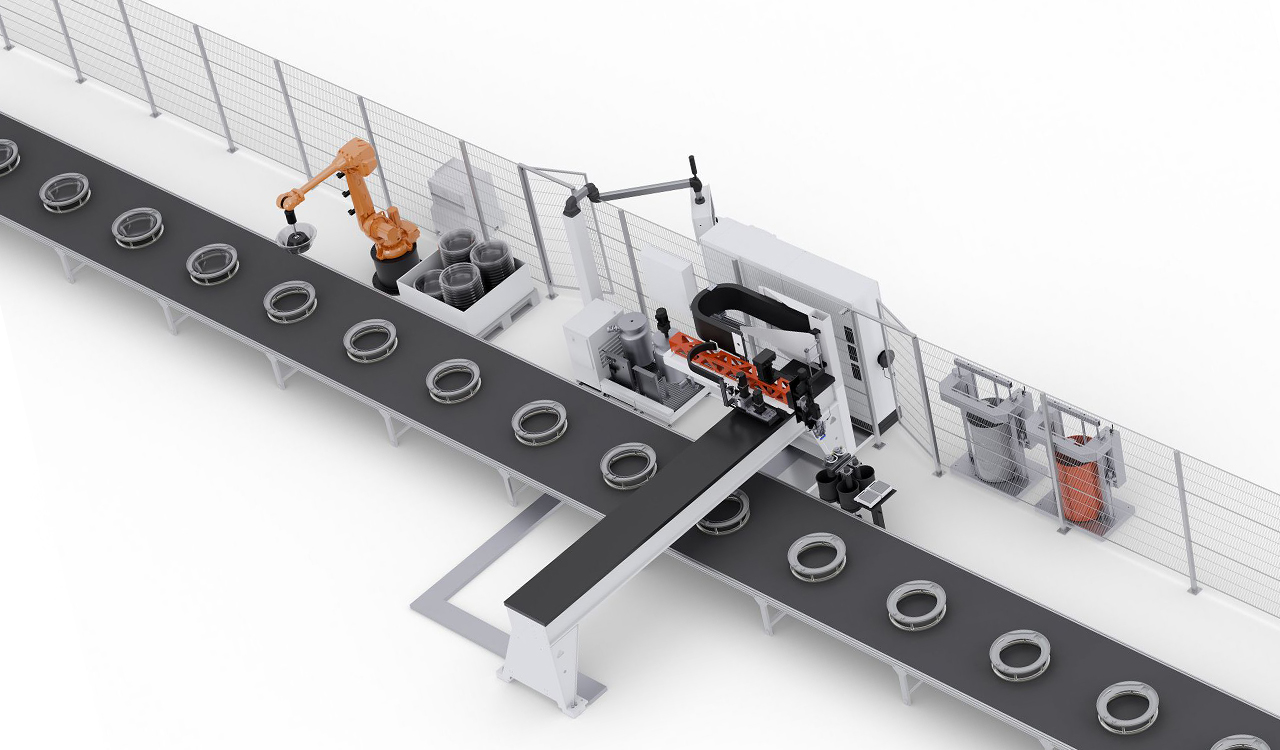

DM502 mixing and dosing system with conveyor belt and 3-axis linear robot for bonding porthole glass elements for washing machines and 6-axis robot for parts handling

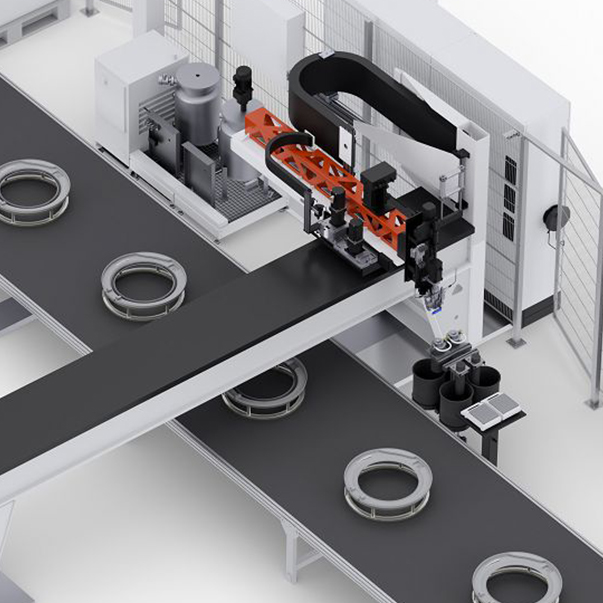

The DM502 mixing and dosing machine, which is integrated into a fully automated production line with a transfer belt for feeding and removing parts, is used to apply adhesive to the plastic mounting frame for bonding porthole glass elements for washing machines.

The MK800 PRO mixing head, which is controlled by the LR-HD 3-axis linear robot, applies the adhesive to the exact contour. The 6-axis robot is used for parts handling.

Alternatively, the MK800 PRO mixing head can also be attached to a 6-axis robot and guided over the component.

The material is supplied by the automatic refilling station, which consists of a drum pumping station (FPS) for each of the A and B components.

Flexible and fully automatic –

to meet your requirements

The reference configuration shown here for the contour-accurate application of the fast-curing 2K silicone structural adhesive LOCTITE® SI 5610 A/B for bonding the porthole/door glazing of washing machines into a mounting frame consists of the DM502 mixing and dispensing system with a 3-axis linear robot and a 6-axis robot for the parts' handling. The components are fed to the mixing and dosing system via a conveyor belt system.

The highly efficient 3-axis linear robot LR-HE plus or alternatively the highly dynamic LR-HD ensures that the MK800 PRO precision mixing head is guided over the component with contour accuracy. The mixing head applies the adhesive to the pre-programmed contour fully automatically with high dosing accuracy.