Sealing of headlights

We offer efficient and flexible sealing solutions to meet your individual requirements for headlights. Our 2-component sealing foam is installed and compressed in the overall part construction of the vehicle light. This keeps moisture away from the light sources and avoids the risk of lighting electronics corroding.

Even though headlights with xenon, LED and laser light technology now represent state-of-the-art vehicle lighting in many markets, there are still countries where cars are sold with conventional headlamps using lightbulbs.

Our customers use FERMAPOR K31 2-component polyurethane foams for sealing these conventional headlights, which are characterized by excellent long-term behavior and very high resilience of the foam structure. The backcap on the back of the headlight can be opened and closed again at any time, e.g. to change the H7 bulb, without the sealing effect weakening.

To compensate for component tolerances, the polyurethane foam can be easily compressed during assembly thanks to a mixed-cell foam structure with low installation forces.

Tailor-made sealing solutions

for headlights

We develop individually for your specific requirements

We offer efficient and flexible sealing solutions to meet your individual requirements for headlights. Our 2-component sealing foam is installed and compressed in the overall part construction of the vehicle light. This keeps moisture away from the light sources and avoids the risk of lighting electronics corroding.

Even though headlights with xenon, LED and laser light technology now represent state-of-the-art vehicle lighting in many markets, there are still countries where cars are sold with conventional headlight technology. Our customers use FERMAPOR K31 2-component polyurethane foams for sealing these conventional headlights, which are characterized by excellent long-term behavior and very high resilience of the foam structure.

The backcap on the back of the headlight can be opened and closed again at any time, e.g. to change the H7 bulb, without the sealing effect weakening. To compensate for component tolerances, the polyurethane foam can be easily compressed during assembly thanks to a mixed-cell foam structure with low installation forces.

Reference material

| FERMAPOR K31-A-5555-1 | FERMAPOR CC-A-5530-2-B | |||

| FERMAPOR K31-B-4 | FERMAPOR CC-B-66 | |||

|

Mixing ratio |

4 : 1 | 2.3 : 1 | ||

|

Pot life time |

35 sec. | 30 sec. | ||

|

Tack-free time |

4 min. | 16 min. | ||

|

Viscosity of A component |

55,000 mPas | 70,000 mPas | ||

|

Density of the foam |

0.27 g/cm³ | 0.31 g/cm³ | ||

|

Hardness (Shore 00) |

54 | 55 | ||

|

Temperature resistance |

from -40 to + 80 °C | from -40 to + 80 °C | ||

|

Pretreatment |

Primer P23 (solvent-based), P13 (water-based) or plasma |

Primer P23 (solvent-based), P13 (water-based) or plasma |

In addition to the reference products, we develop material systems according to your individual requirements. Influencing factors include pot life until start of foaming, curing time, and the viscosity, hardness and adhesion properties.

Repeatedly opening and reclosing for maintenance purposes with remaining sealing effect

The very good resilience of the foam seal allows the components to be opened and reclosed repeatedly for maintenance purposes without the tightness deteriorating. After installation, the headlight is sealed and the sensitive electronics are protected against splashing water and the effects of the weather.

The video shows the polyurethane foam seal FERMAPOR K31 in a cross section in a groove - first in the uncompressed state, then about 50 % compressed, so that the sealing function of the seal is given and the component is tight.

Cross-section of a polyurethane foam bead in the groove without compression.

Cross-section of a polyurethane foam bead in the groove and compressed to approx. 50 %.

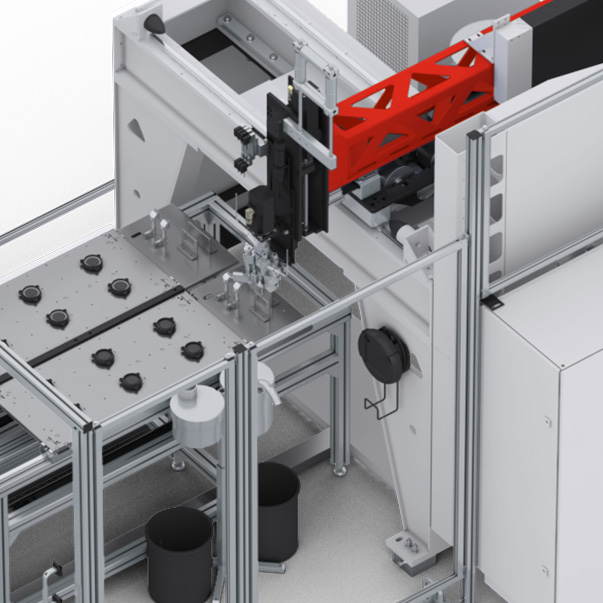

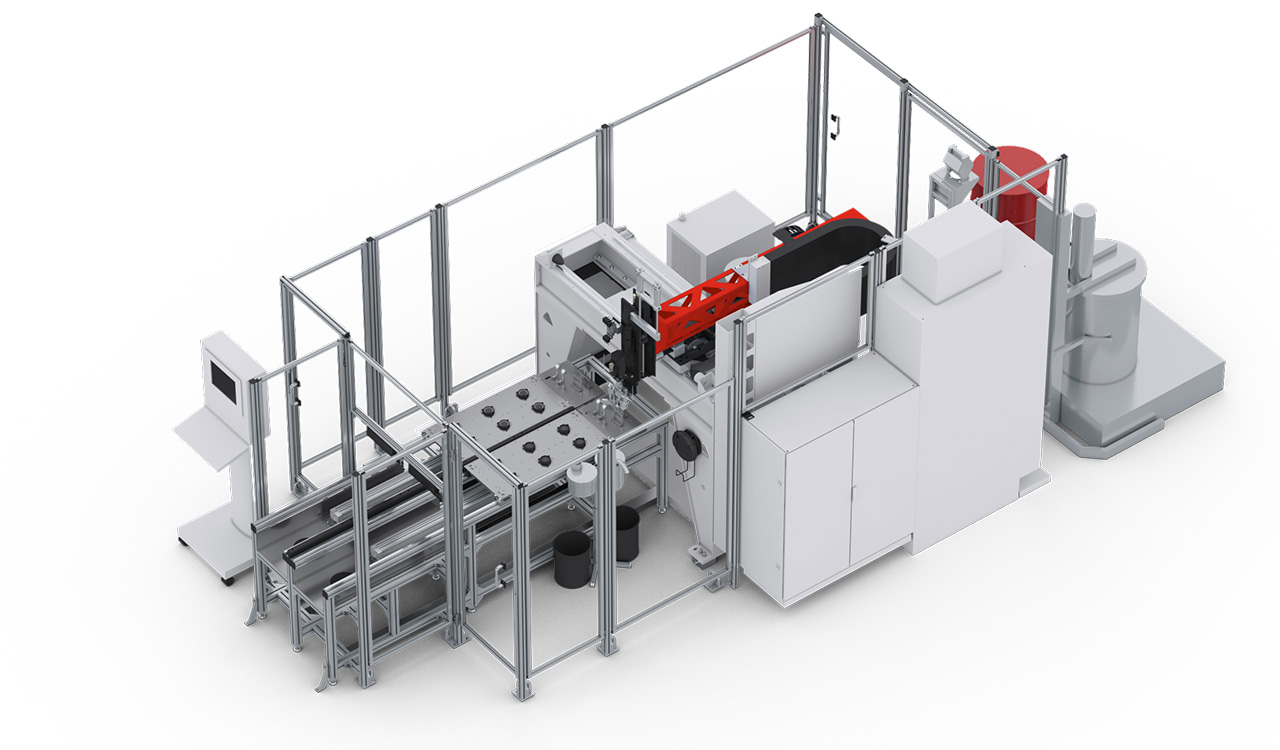

DM 502 mixing and dosing system with 3-axis linear robot and a shuttle table for picking parts of the headlight backcaps

The reference configuration shown here for sealing the backcaps of headlights consists of our DM 502 mixing and dosing system with an LR-HE 3-axis linear robot as well as a WT 1-LEVEL shuttle table for picking up parts. The two pick-up plates working in pendulum mode enable the workpieces fixed there to be picked up and processed in one plane. This makes it possible to guarantee continuous operation.

The placement and holding on the shuttle table of the headlight housing to be sealed is performed either by a machine operator, who can also check the parts for quality, or by a Pick & Place Robot. In such a case, an optionally installed camera or sensor system could carry out the quality control of the parts.

Flexible and fully automatic – according to your requirements

For sealing the headlights, FERMAPOR K31 thixotropic polyurethane sealing foam is applied through the nozzle of the CNC-controlled MK 825 PRO mixing head, in a high-precision and fully automatic process, onto the 2D or 3D application surface or into the groove of the component contour.

After the dosing cycle, the coupling point of the foam gasket closes almost seamlessly and is thus virtually invisible. Due to the uniform compression in the installed state, a high level of tightness is achieved over the entire contour of the backcaps.

For improved adhesion of the foam gasket to plastics such as PP or PE using plasma, we install an optional plasma application unit on the rear of the CNC Y-axis in addition to the mixing head.

Even with short cycle times and high unit numbers, the material application process using the FIPFG method is carried out with high dosing precision and repeat accuracy. As a result, you achieve foam gaskets of uniformly high quality. This means that your sealed headlights can be processed rapidly, right through to final assembly. This saves time and money.

In addition, our fail-safe mixing and dosing system can be operated easily and intuitively without the need for extensive training. Due to the automatic logging of dosing program data, all process data can be traced and evaluated by the machine operator while production is running.

Material pressure tanks

Supply Tap

Elevator

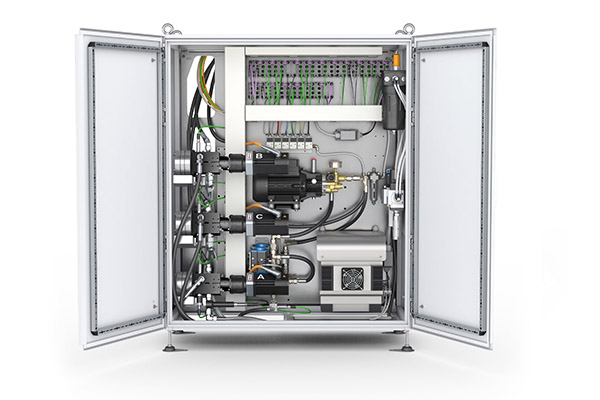

Control cabinet

Dosing machine cabinet

MP 2 mobile panel

Mixing head 825 PRO

WT 1-LEVEL shuttle / sliding table

CONTROL 2

Material pressure tanks

Supply Tap

Elevator

Control cabinet

Dosing machine cabinet

MP 2 mobile panel

Mixing head 825 PRO

WT 1-LEVEL shuttle / sliding table

CONTROL 2

Material pressure tanks

"Material pressure tanks (24 l or 44 l, single-walled or double-walled) with minimum level sensors, on a grating platform with adjustable leveling feet and drip tray"

More information to our material pressure tanksSupply Tap

Optional: Automatic SUPPLY TAP drum refilling station for low-viscosity products, e.g. isocyanate (B-component)

More information to our refilling stationsElevator

Optional: Automatic ELEVATOR drum refilling station for the A-component with pneumatic lift and agitator

More information to our refilling stationsControl cabinet

The control electronics, safety engineering and industrial PC are installed in the control cabinet.

More information to our control cabinetsDosing machine cabinet

The dosing machine cabinet contains the components of the dosing periphery, e.g. the dosing pumps.

More information to our dosing machine cabinetsMP 2 mobile panel

The multifunctional MP 2 mobile panel (10.1” WXGA TFT) enables convenient operation of the dosing system.

More information to our operating panelsMixing head 825 PRO

MK 800 PRO precision mixing head with high-pressure water rinsing or alternative component rinsing system

More information to our mixing headsWT 1-LEVEL shuttle / sliding table

Two pick-up plates operating in pendulum mode in one plane

More information to our shuttle tablesCONTROL 2

Optionally available: CONTROL touchscreen operating panel (21.5“) for operating the dosing system

More information to our operating panels