FERMAPOR CC

Tailor-made polyurethane closed-cell sealing foam system for growing requirements

FERMAPOR CC material systems are addition cross-linking 2-component systems for the manufacture of soft polyurethane foams. The main elements of the A component are polyfunctional alcohols, the polyols. The B component consists of the aromatic MDI isocyanate and its derivatives.

When component A is mixed with component B, a chemical reaction starts that, together with the developed FIP-CC process, leads to the formation of a predominantly closed-cell polyurethane soft foam.

For further information please do not hesitate to contact us.

Low water absorption even for damaged surfaces

FERMAPOR CC with its smooth, slightly shiny surface gives an optically high-quality appearance. Its foam structure has very fine cells, is impermeable and extremely uniform.

Even if the surface should become damaged during application, practical trials and laboratory tests have shown that there is only a marginal change in water absorption.

Usual processing conditions - typical polyurethane

As soon as the foam has completely hardened, it can be used for applications with high sealing and quality requirements. The operating temperature range lies between -40° to +80 °C, and in the short term even up to +160 °C dependent on the test conditions, and is tested under real conditions appropriate to the application.

The exact hardening time is dependent on external factors such as temperature, humidity, and sealing dimension and it is also evaluated specifically for the sealed part.

Proven and new benefits - typical polyurethane

- Predominantly closed-cell, therefore very low water absorption

- Ice water resistant at water temperatures up to 1 °C

- No oven or humidity necessary for curing

- Very robust, mounting-proof sealing surface

- Low water absorption even after damage to the sealing surface (e. g. cracks)

- Cost effective polyurethane alternative to 1-component and silicone applications

- Formulation can be customized like mixed-cell 2-component PU

- Thixotropic and half-thixotropic formulations available

- Shrinking is no more possible

- Meets the standards REACH, EC Regulation 1907/2006, RoHS

Diversity of formulations - typical polyurethane

Because FERMAPOR CC is formulated on a polyurethane basis, the know-how based on over 1,000 polyurethane formulations from Henkel is available for the variations of FERMAPOR CC.

Our extensive experience in developing customer-specific material systems is also completely used for this new material system. Feel free to contact us; we will be pleased to develop the suitable material solution for your requirement.

The exact interaction of different setting parameters and additional functions of the mixing and dosing machines, the exact matching of the component and FERMAPOR K31 foam seal in the overall design and the correct choice of material are what make a truly reliable seal of industrial components for the most diverse applications against moisture, dust and other environmental influences possible.

FERMAPOR CC - Processing Information

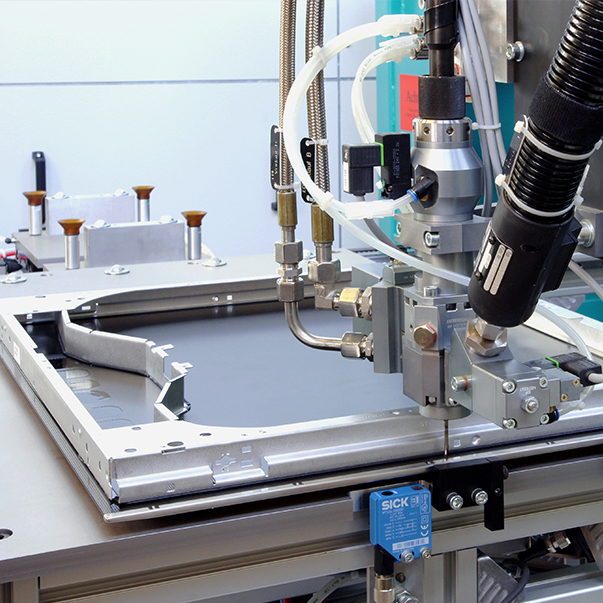

FERMAPOR CC systems are processed with 2-component medium-pressure SONDERHOFF mixing and dosing machines from Henkel. The recommended processing temperature is +23° +/- 5 °C. Generally, FERMAPOR CC components have a shelf-life for at least 6 months at storage temperatures from +10° up to +40 °C.

| PHYSICAL AND CHEMICAL PROPERTIES | ||

|---|---|---|

| Property | FERMAPOR CC | |

| Appearance | black, other colours on request | |

| Hardness | from 40 to 70 Shore 00 | |

| Compression resistance (25 % compression) | > 20 kPa | |

| Bulk density | from 0.30 g/cm3 to 0.50 g/cm3 | |

| Temperature resistance | from -40 °C to +80 °C (short term up to +160 °C) | |

| Tensile strength | from 150 kPa to 500 kPa | |

| Elongation at break | 100 % to 150 % | |

| Resilience (compression set) | > 95 % dependent on the test conditions | |

| Water absorption | < 10 % (material is already waterproofed) | |