Sealing of third brake lights

To ensure that your innovative vehicle lighting systems can function reliably, we offer you efficient and flexible sealing solutions to meet your individual requirements. Our 2-component sealing foam is installed and compressed in the overall part construction of the vehicle light. This keeps moisture away from the light sources and thus avoids the risk of lighting electronics corroding. The polyurethane based 2-component sealing foams can be applied to a wide range of applications on cars, vans and trucks: front headlights, tail lights, third brake lights, turn signals, rear fog lights, license plate lights and multifunctional lights.

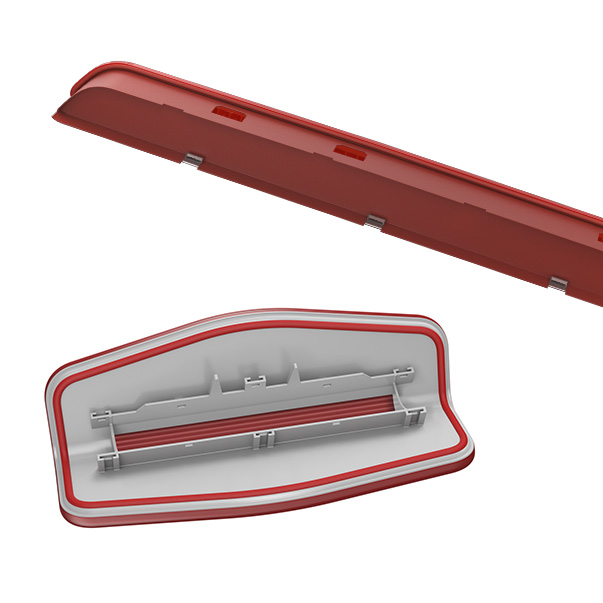

Third brake lights, installed in rear spoilers or on rear windows with 2-dimensional and 3-dimensional geometry are often sealed using the FERMAPOR K31 thixotropic polyurethane foams, because these adapt excellently to the 3D contour. Using the FIPFG process, our dosing equipment applies a small, fine foam bead to the contact surface or in the groove, ensuring reliability under process conditions and stability guaranteed by the high foam viscosity.

FERMAPOR K31 seals are therefore ideally suited for a majority of designs of third brake lights. Although we can produce the sealing material in a variety of colors, the seal in this case is typically red in color and not visible under the red cover of the brake light.

Tailor-made sealing solutions

for third brake lights

We develop individually for your specific requirements

Our polyurethane foams are highly water-repellent and temperature-resistant from -40 to +80 °C. They achieve particularly good adhesion to the contact surfaces of common plastic materials. For plastics such as PP or PE, adhesion is often achieved through additional pretreatment with plasma or primer. Due to excellent long-term behavior and the very high resilience of the foam gasket, repeated removal and installation of third brake lights for repair purposes is possible without the sealing effect decreasing.

To compensate for component tolerances, the polyurethane foam can be easily compressed during assembly thanks to a mixed-cell foam structure with low installation forces. We can modify our formulations to meet many of your requirements.

Reference material

| FERMAPOR K31-A-9212-1-rot | FERMAPOR CC-A-5530-2-B | |||

| FERMAPOR K31-B-81 | FERMAPOR CC-B-66 | |||

|

Mixing ratio |

3.7 : 1 | 2.3 : 1 | ||

|

Pot life time |

35 sec. | 30 sec. | ||

|

Tack-free time |

5 min. | 16 min. | ||

|

Viscosity of A component |

46,000 mPas | 70,000 mPas | ||

|

Density of foam |

0.25 g/cm³ | 0.31 g/cm³ | ||

|

Hardness (Shore 00) |

36 | 55 | ||

|

Temperature resistance |

from -40 to + 80 °C | from -40 to + 80 °C | ||

|

Pretreatment |

Primer P23 (solvent-based), P13 (water-based) or plasma |

Primer P23 (solvent-based), P13 (water-based) or plasma |

In addition to the reference products, we develop material systems according to your individual requirements. Influencing factors include pot life until start of foaming, curing time, and the viscosity, hardness and adhesion properties.

Repeatedly opening and reclosing for maintenance purposes with remaining sealing effect

The very good resilience of the foam seal allows the components to be opened and reclosed repeatedly for maintenance purposes without the tightness deteriorating. After installation, the third brake light is sealed and the sensitive electronics are protected against splashing water and the effects of the weather.

The video shows the polyurethane foam seal FERMAPOR K31 in cross section - first in the uncompressed state, then 50 % compressed, so that the sealing function of the seal is given.

Cross-section of a polyurethane foam bead – unpressed.

Cross-section of a polyurethane foam bead with 50 % compression.

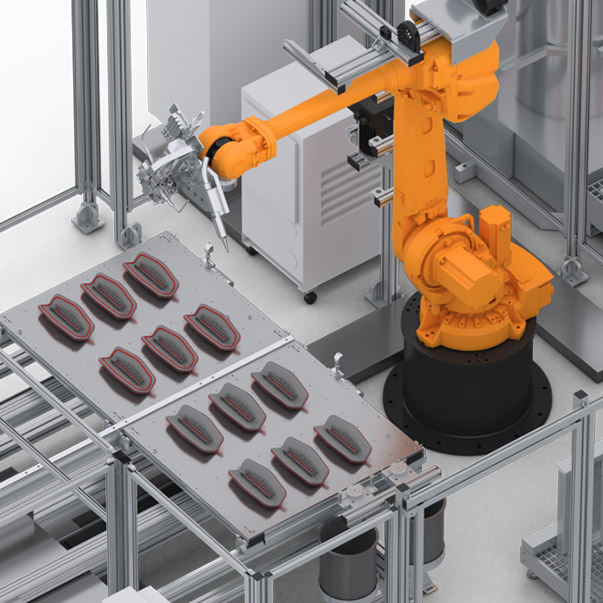

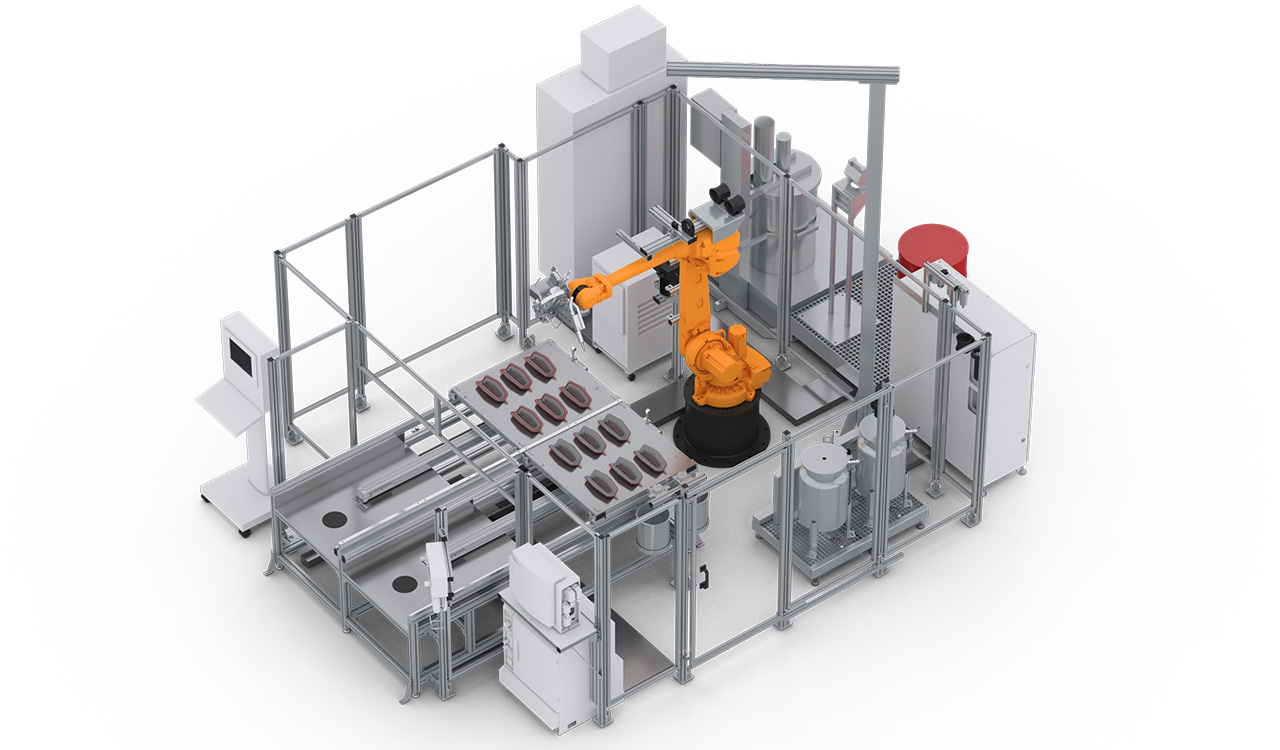

DM 502 mixing and dosing system with 6-axis robot and mixing head for foam application and shuttle table for picking up parts for the third brake lights

The reference configuration shown here for sealing the housings of third brake lights consists of our DM 502 mixing and dosing system with 6-axis robot and MK 825 mixing head for foam application as well as a WT 1-LEVEL shuttle table for picking up parts.

The two pick-up plates working in pendulum mode enable the workpieces fixed there to be picked up and processed in one plane. This makes it possible to guarantee continuous operation.

The placement and holding on the shuttle table of the third brake light housing to be sealed is performed either by a machine operator, who can also check the parts for quality, or by a Pick & Place Robot. In this case, an optionally installed camera system could carry out the quality control of the parts.

Flexible and fully automatic – according to your requirements

For sealing third brake lights, FERMAPOR K31 thixotropic polyurethane sealing foam is applied via the nozzle injector of the MK 825 mixing head mounted on the robot arm, in a high-precision and fully automatic process, onto the 2D or 3D application surface or into the groove of the component contour. After the dosing cycle, the coupling point of the foam gasket closes almost seamlessly and is thus virtually invisible. Due to the uniform compression in the installed state, a high level of tightness is achieved over the entire contour of the third brake light.

For improved adhesion of the foam gasket to plastics such as PP or PE using plasma, we install an optional plasma application unit on the robot arm in addition to the mixing head.

Even with short cycle times and high unit numbers, the material application process using the FIPFG method is carried out with high dosing precision and repeat accuracy. As a result, you achieve foam gaskets of uniformly high quality. This means that your sealed third brake lights can be processed rapidly, right through to final assembly. This saves time and money.

In addition, our fail-safe mixing and dosing system can be operated easily and intuitively without the need for extensive training. Due to the automatic logging of dosing program data, all process data can be traced and evaluated by the machine operator while production is running

Control cabinet

Elevator

Supply Tap

Material pressure tanks

Dosing machine cabinet

Mixing head 825 PRO

WT 1-LEVEL shuttle / sliding table

CONTROL 2

MP 2 mobile panel

Control cabinet

Elevator

Supply Tap

Material pressure tanks

Dosing machine cabinet

Mixing head 825 PRO

WT 1-LEVEL shuttle / sliding table

CONTROL 2

MP 2 mobile panel

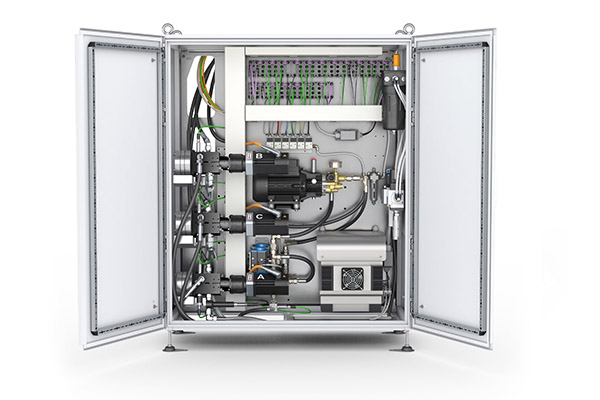

Control cabinet

The control electronics, safety engineering and industrial PC are installed in the control cabinet.

More information to our control cabinetsElevator

Optional: Automatic ELEVATOR drum refilling station for the A-component with pneumatic lift and agitator

More information to our refilling stationsSupply Tap

Optional: Automatic SUPPLY TAP drum refilling station for low-viscosity products, e.g. isocyanate (B-component)

More information to our refilling stationsMaterial pressure tanks

Material pressure tanks (24 l or 44 l, single-walled or double-walled) with minimum level sensors, on a grating platform with adjustable leveling feet and drip tray

More information to our material Pressure TanksDosing machine cabinet

The dosing machine cabinet contains the components of the dosing periphery, e.g. the dosing pumps.

More information to our dosing machine cabinetsMixing head 825 PRO

MK 800 PRO precision mixing head with high-pressure water rinsing or alternative component rinsing system

More information to our mixing headsWT 1-LEVEL shuttle / sliding table

Two pick-up plates operating in pendulum mode in one plane

More information to our shuttle tablesCONTROL 2

Optionally available: CONTROL touchscreen operating panel (21.5“) for operating the dosing system

More information to our operating panelsMP 2 mobile panel

The multifunctional MP 2 mobile panel (10.1” WXGA TFT) enables convenient operation of the dosing system.

More information to our operating panels