Sealing of linear luminaires

To ensure that lighting systems function reliably, whether in neon tubes, energy-saving bulbs, halogen or LED lighting technology, the luminaire housing needs to be sealed against moisture, dust and other environmental conditions.

Thanks to the excellent long-term behavior of our sealing foams, we meet your requirements for resistance to the influence of temperature and UV, as well as preventing the penetration of water and dust into the luminaire housings, corresponding to IP protection classes and NEMA enclosure types.

Moisture in wet rooms can lead to short circuits causing considerable damage to the light fittings and their electrical connections. Special linear luminaires, known as damp-proof luminaires, are used in wet rooms and unprotected outdoor areas.

The housings of these light fittings are seamlessly sealed with a 2-component polyurethane foam from the FERMAPOR K31 product family. This is achieved using our dosing technology through the precise application of the still-liquid material into the housing groove.

Foaming in the groove creates a soft foam gasket, which cures at room temperature and has a virtually invisible joint.

Reliably protecting lamps and

lighting electronics in linear luminaires

The closing mechanism used for sealing the transparent covers of linear luminaires works by pressing the foam gasket into the housing groove. This seals the light fixture ensuring that moisture is unable to penetrate inside the housing.

Thanks to the good resilience of the foam gasket, the luminaire cover can be opened and closed again for maintenance purposes, while maintaining a consistently tight seal. Our sealing foams can be adjusted to be very soft for easier closing. This also prevents bending in housings with thinner walls.

Special 2-component silicone sealing foams from the FERMASIL product family likewise meet the stringent requirements for ATEX approval of your explosion-protected luminaires, as summarized in the IEC 60079 standard for electrical equipment with explosion protection. They are suitable for luminaire housings used in explosive hazardous environments, such as in the mining industry or on off-shore drilling platforms.

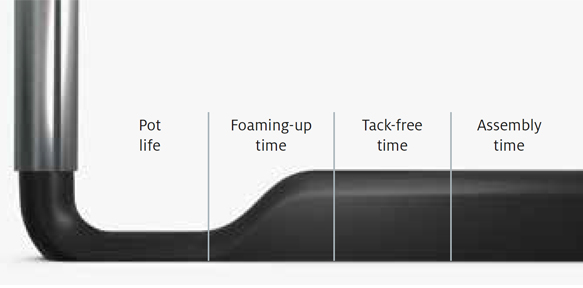

The different reaction phases of the sealing foam in the chronological sequence

Reference material

| Lighting Indoor |

Lighting Outdoor |

Ex (e. g. mining, off-shore oil platform) |

||

| FERMAPOR K31-A-9675-5-VP | FERMAPOR K31-A-9675-2-VP | FERMASIL-A-91-VP2 | ||

| FERMAPOR K31-B-4 | FERMAPOR K31-B-4 (UL 50e) | FERMASIL-B-91 | ||

| Mixing ratio | 4.5 : 1 | 4 : 1 | 1 : 1 | |

| Pot life time | 40 sec. | 38 sec. | 56 sec. | |

| Tack-free time | 7.0 min. | 3.5 min. | 5.0 min. | |

|

Viscosity of the |

1,500 mPas | 1,800 mPas | 15,000 mPas | |

| Density of foam | 0.23 g/cm³ | 0.34 g/cm³ | 0.30 g/cm³ | |

| Hardness (Shore 00) |

43 | 64 | 52 | |

| Temperature resistance |

from -40 to + 80 °C | from -40 to + 80 °C | from -60 to +180 °C | |

| Pretreatment | Plasma, Corona or Primer | Plasma, Corona or Primer |

Primer P8 or TEROSON SB450 |

In addition to the reference products, we develop material systems according to your individual requirements. Influencing factors include pot life until start of foaming, curing time, and the viscosity, hardness and adhesion properties.

Repeated opening and reclosing of the linear luminaires with remaining sealing effect

Thanks to the good resilience of the foam gasket, the luminaire cover can be opened and closed again for maintenance purposes, while maintaining a consistently tight seal.

After closing, the housing is tight and the sensitive luminaires are protected against splash water and the effects of the weather.

Linear luminaire in the open state, the seal is uncompressed

Linear luminaire in closed position, the seal is compressed

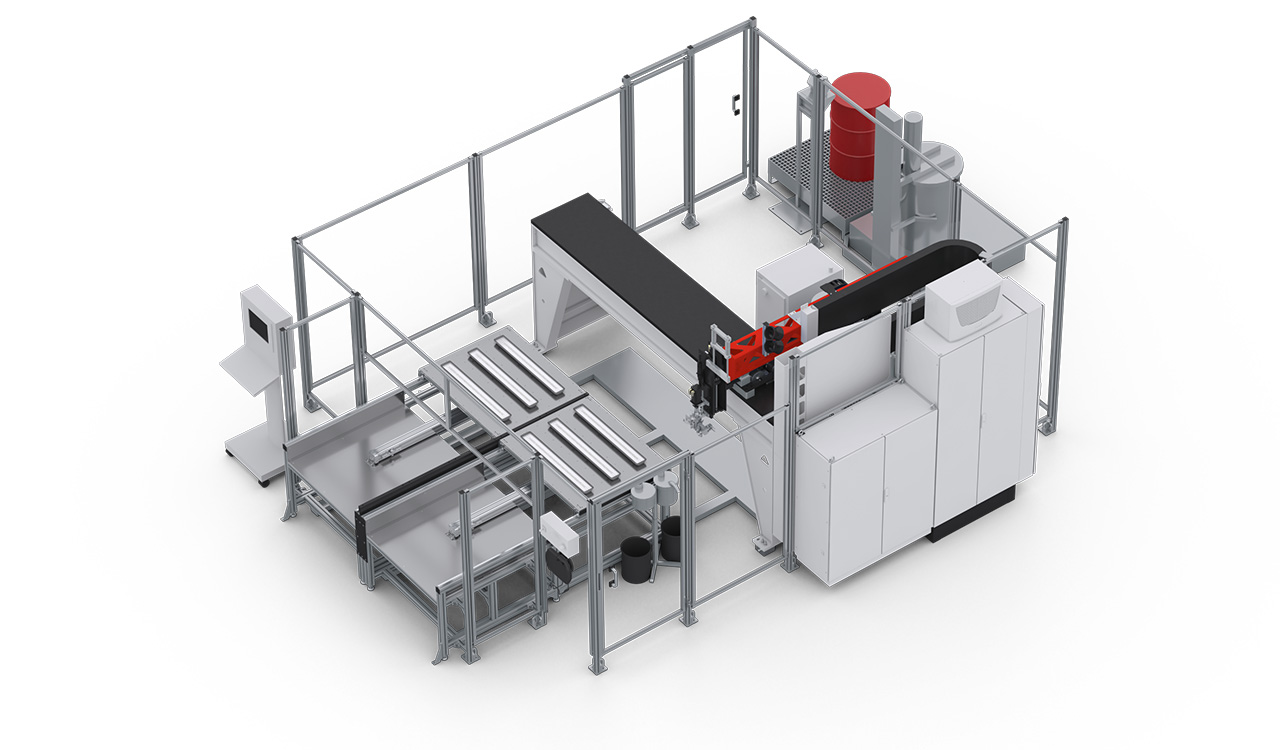

DM 502 mixing and dosing system with 3-axis linear robot

and a shuttle table for the parts holder

Flexible and fully automatic –

according to your requirements

As process experts, we support you with our application engineering expertise, from the design phase for your components through to fully automated material application using formed-in-place-foam-gasket (FIPFG) technology.

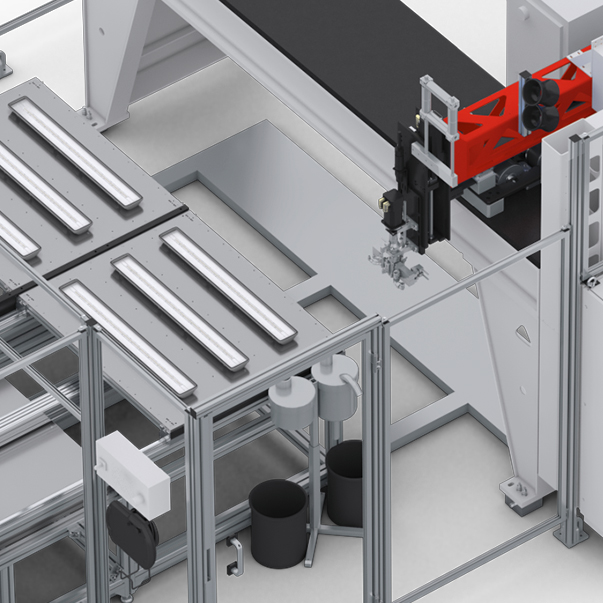

Our flexibly configurable DM 502 mixing and dosing system has a 3-axis linear robot and sliding table solution, and can be adapted to your production concept for the seal-foaming of luminaire housings or for LED potting.

To this end, we offer equipment options for semi-automatic or fully automatic production systems. If desired, CNC-controlled plasma application is also possible to achieve surface activation of the housing contour, resulting in better adhesion of the foam gasket to plastics such as PP or PE.

The reference configuration shown here for sealing linear luminaires consists of the DM 502 mixing and dosing system with LR-HD 3-axis linear robot and WT 1-LEVEL shuttle table for picking up parts. Two alternately operated pick-up plates facilitate continuous operation by allowing workpieces to be fixed and processed in a single plane.

The positioning of the luminaire housings on the pick-up plate is performed either by a machine operator, who can also check the parts for quality, or by a Pick & Place Robot. In the latter case, a camera or sensor system can optionally be installed to perform quality control on the parts.

The material components of the sealing foam used are mixed dynamically and homogeneously in the mixing head of the DM 502. The resulting fine-cell foam structure is crucial for low water absorption levels. For material application using the FIPFG process, the MK 825 PRO precision mixing head is moved over the housing groove of the linear luminaire with high repeat accuracy by the CNC-controlled linear robot, and the sealing material is applied into the groove in accurately metered doses via the mixing head nozzle. The dosing loop completes the foam gasket with a seamless, almost invisible coupling point.

Highly efficient and precise material application by the DM 502 allows quick application processes in your production facility, and rapid processing of the parts through to final acceptance.

CONTROL 2

MP 2 Mobile panel

WT 1-LEVEL shuttle / sliding table

Mixing head 825 PRO

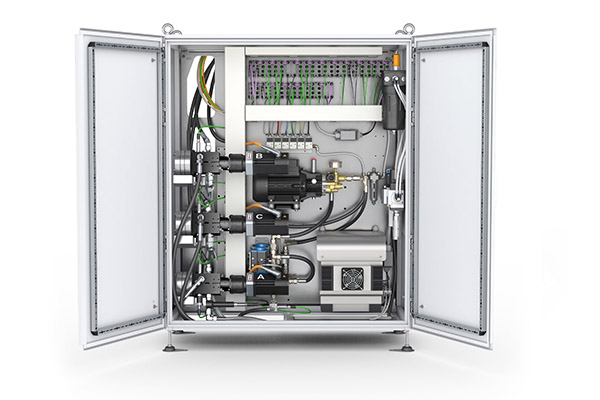

Dosing machine cabinet

Control cabinet

Supply Tap

Elevator

CONTROL 2

MP 2 Mobile panel

WT 1-LEVEL shuttle / sliding table

Mixing head 825 PRO

Dosing machine cabinet

Control cabinet

Supply Tap

Elevator

CONTROL 2

Optionally available: CONTROL touchscreen operating panel (21.5“) for operating the dosing system

More information to our operating panelsMP 2 Mobile panel

The multifunctional MP 2 mobile panel (10.1” WXGA TFT) enables convenient operation of the dosing system.

More information to our operating panelsWT 1-LEVEL shuttle / sliding table

Two pick-up plates operating in pendulum mode in one plane

More information to our shuttle tablesMixing head 825 PRO

MK 800 PRO precision mixing head with high-pressure water rinsing or alternative component rinsing system

More information to our mixing headsDosing machine cabinet

The dosing machine cabinet contains the components of the dosing periphery, e.g. the dosing pumps.

More information to our dosing machine cabinetsControl cabinet

The control electronics, safety engineering and industrial PC are installed in the control cabinet.

More information to our control cabinetsSupply Tap

Optional: Automatic SUPPLY TAP drum refilling station for low-viscosity products, e.g. isocyanate (B-component)

More information to our refilling stationsElevator

Optional: Automatic ELEVATOR drum refilling station for the A-component with pneumatic lift and agitator

More information to our refilling stationsThe basic solution for standard applications

Dosing cell for easy handling and high process stability

The reference configuration of the 3E dosing cell shown is a low-pressure mixing and dosing system for two components for the partially and fully-automatic application of sealing foams.

The already compact design of the 3E dosing cell also takes up little space as a result because, as a CE-compliant dispensing cell, it does not require any additional safety fences or light barriers.

This is a pre-programmed Plug & Work version that is delivered pre- assembled in a container. As soon as electricity, water and compressed air are connected and the material is prepared in the material pressure tanks, production can begin. The costs of installation and training courses can therefore be kept to a minimum.

The dosing cell can process non-viscous, medium-viscosity and highly viscous material systems based on polyurethane. The application rate is adjustable from 0.5 to 5.0 g/s. Experience shows that this range covers 90% of industrial applications.

The optional shuttle table allows components of different sizes to be processed in a single plane. Continuous operation is guaranteed by the two pick-up plates that can be moved manually in alternation. For larger parts, the two pick-up plates can be connected to form one large sliding table.

The CNC-controlled MK 825 BASIC precision mixing head for two material components applies sealing material into the housing groove of the linear luminaires with contour precision. With the sometimes very narrow and deep grooves, the metering of the sealing foams needs to be very precise.

The MK 825 BASIC precision mixing head performs this task with high metering precision and repeat accuracy. The dosing loop completes the foam gasket with a seamless, almost invisible coupling point.

With the CE-compliant 3E dosing cell, an immediate, safe start to production is possible, as well as efficiency-enhancing space and cost savings.