Customized sealing solution for vacuum cleaner HEPA filters

Sealing of filter frames with seal foam and bonding of filter pack into the frame

The reference materials presented here are polyurethane-based, room-temperature curing 2-component sealing foam and adhesive sealant systems that have already proven their value through many years of use by leading filter manufacturers. They are applied directly to the component using FIPFG (Formed-In-Place-Foam-Gasket) technology and our fully automated dosing machines, very precisely, safely and efficiently.

FERMAPOR K31-A-9025-2-VP2 and B-4 (B component) polyurethane sealing foam is used for sealing the filter frames of HEPA filters for vacuum cleaners.

The adhesive sealant FERMADUR A-196-9-VP1 and B-N (B component) is available for bonding the filter packs in the filter frames.

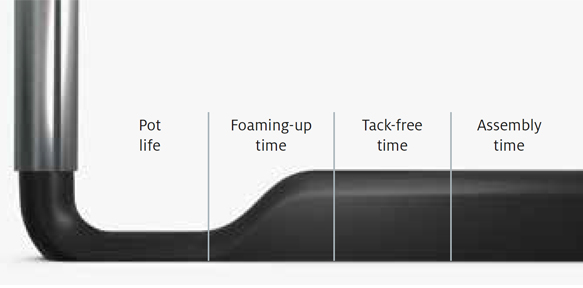

Whenever possible, we can also customize our material systems to meet your specific requirements. Influencing factors include pot life until start of foaming, curing time, and the viscosity, hardness and adhesion properties.

Customized sealing and bonding solutions for vacuum cleaner HEPA filters

The FERMAPOR K31 foam gasket has an excellent resetting ability and shows excellent long-term behavior even after years of continuous use due to compression of the foam cell structure.

Potential component tolerances of the filter frame are compensated for when sealing with the soft foam gasket. The low closing forces thanks to mixed-cell foam structure facilitate installation of the foamed HEPA filter frame in the vacuum cleaner.

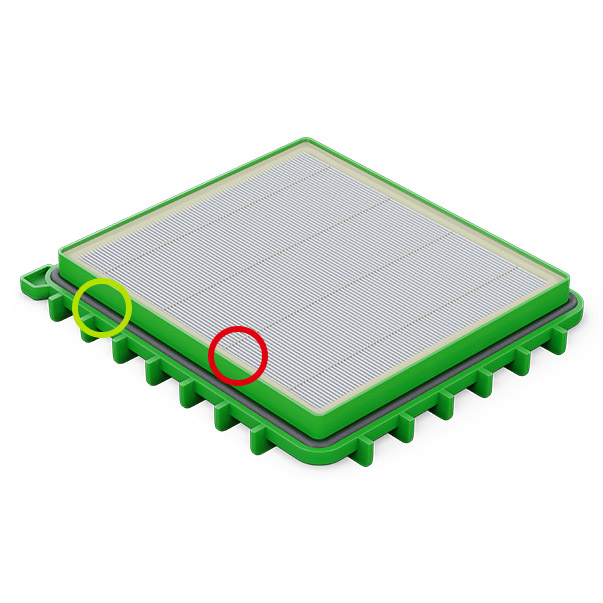

The picture shows PU foam sealing of filter frames (yellow circle) and frame bonding of filter packs with PU adhesive sealant (red circle).

The different reaction phases of the sealing foam in the chronological sequence

Repeated installation and removal of HEPA filter for maintenance purposes

The very good resetting ability of the FERMAPOR K31 polyurethane foam gasket allows repeated installation and removal of the HEPA filter for maintenance purposes without the seal tightness decreasing.

Cross-section of a polyurethane foam bead – unpressed

Cross-section of a polyurethane foam bead with 50 % compression

In addition to the compact FERMADUR adhesive sealants, we also offer foamed filter adhesives with a lower density for bonding the filter packs in the filter frames. The amount of adhesive per filter can therefore be reduced by up to 50 percent. The lower weight also ensures lighter and therefore easier parts handling. Both save money while still satisfying the requirements for high-quality filter bonding.

The good flow properties of FERMADUR adhesive sealants ensure they are applied to the entire surface on the inside of the filter frame and the filter pack. The filter pack positioned in the filter frame is therefore optimally bonded and sealed on all sides.

Sealing foams and adhesive sealants are cured at room temperature, saving the expense of the annealing oven required by other methods.

Reference material

| FERMAPOR K31-A-9025-2-VP2 | FERMADUR-A-196-9-VP1 | ||

| FERMAPOR K31-B-4 | FERMADUR-B-N | ||

| Mixing ratio | 4.5 : 1 | 2.8 : 1 | |

| Pot life time | 33 sec. | 67 sec. | |

| Tack-free time | 5 min. | 3 min. | |

|

Viscosity of the A component |

44,000 mPas | 6,100 mPas | |

| Density of the foam | 0.2 g/cm³ | 1.27 g/cm³ | |

| Hardness | 35 (Shore 00) | 87 (Shore A) | |

|

Temperature resistance |

from -40 to + 80 °C | from -40 to + 80 °C | |

| Pretreatment | Plasma, Corona, Primer | Plasma, Corona, Primer |

In addition to the reference products, we develop material systems according to your individual requirements. Influencing factors include pot life until start of foaming, curing time, and the viscosity, hardness and adhesion properties.

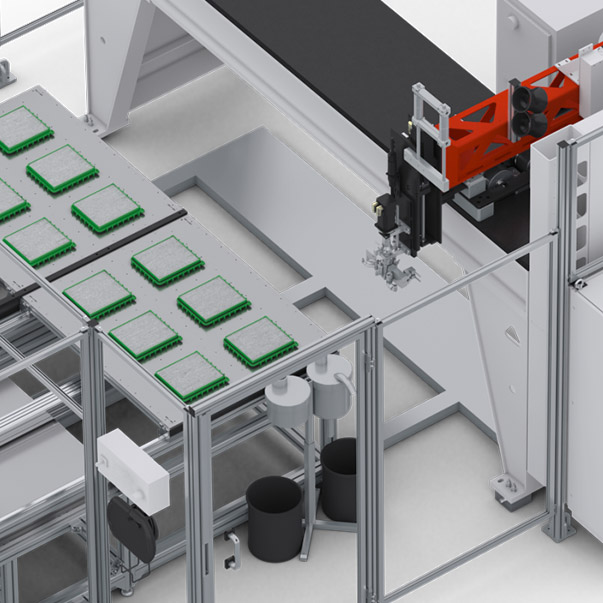

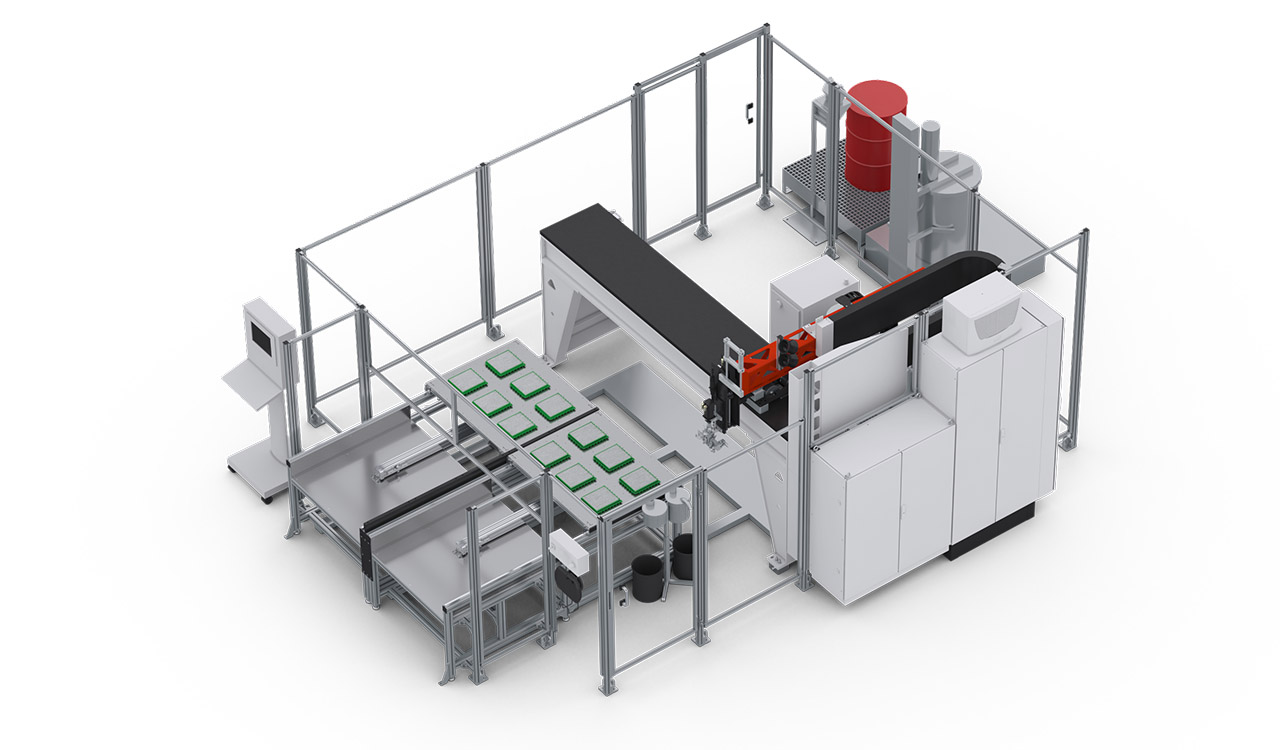

DM 503 mixing and dosing system for 3 components for simultaneous sealing of filter frames and bonding of HEPA filter packs

Flexible and fully automatic – fully in line with your requirements

The reference configuration shown here for sealing filter frames with polyurethane sealing foam and bonding filter packs in the filter frames with adhesive sealant consists of the DM 503 mixing and dosing system for 3 components with the LR-HD 3-axis linear robot and the WT 1-LEVEL shuttle table.

Parts are picked up and processed in continuous shuttle mode in one plane. Alternatively, we offer the WT 2-LEVEL shuttle table with pick-up plates operating in shuttle mode, one above the other in two planes.

The components are placed either by a machine operator, who can also check the parts for quality, or by a Pick & Place Robot. In the latter case, an optionally installed camera system could perform quality control of the parts.

The advantage of this system configuration in which 3 material components are used is that both seal foaming and bonding can be carried out with the same dosing system.

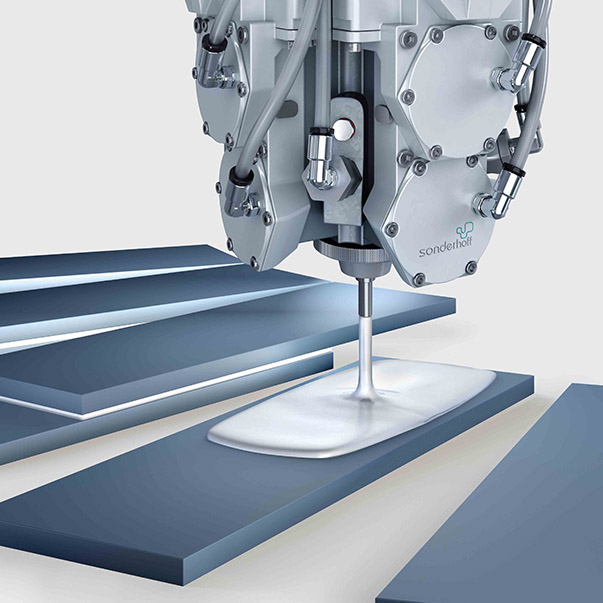

The highly dynamic LR-HD 3-axis linear robot or, alternatively, the highly efficient LR-HE plus ensures contour-accurate guidance of the MK 800 PRO precision mixing head over the component. In this process, the FERMAPOR K31 sealing foams are applied to the pre-programmed contour of the filter frame fully automatically and with high dosing accuracy.

After the dosing cycle, the coupling point of the foam gasket closes seamlessly and is therefore almost invisible. The applied material expands to several times its volume and forms an elastic soft foam gasket at room temperature with the desired foam hardness, which usually achieves excellent adhesion to the component.

The 2-component FERMADUR adhesive sealants are applied via the mixing head to the outer edges of the filter pack and simultaneously to the inner sides of the filter frame in a process-reliable manner. This creates a full-surface bond, with which the filter pack is optimally bonded and sealed on all sides in the frame.

Our fail-safe mixing and dosing systems can be operated easily and intuitively without the need for extensive training. Thanks to the automatic logging of dosing program data, all process data can be traced and evaluated by the machine operator via the CONTROL 2 operating panel while production is running.

As process experts, we support you with tailored advice for the automation of your manufacturing processes.

CONTROL 2

MP 2 Mobile panel

WT 1-LEVEL shuttle / sliding table

Mixing head 825 PRO

Supply Tap

Elevator

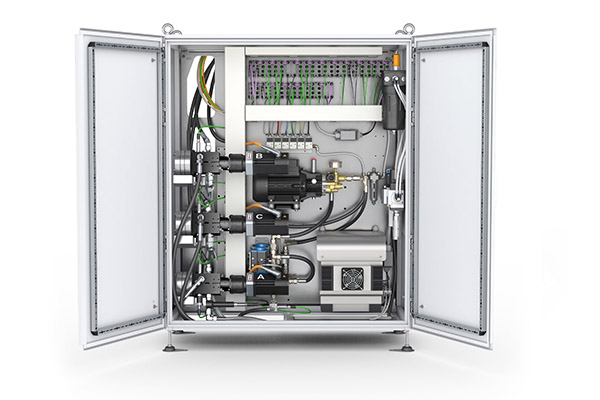

Dosing machine cabinet

Control cabinet

CONTROL 2

MP 2 Mobile panel

WT 1-LEVEL shuttle / sliding table

Mixing head 825 PRO

Supply Tap

Elevator

Dosing machine cabinet

Control cabinet

CONTROL 2

Optionally available: CONTROL touchscreen operating panel (21.5“) for operating the dosing system

More information to our operating panelsMP 2 Mobile panel

The multifunctional MP 2 mobile panel (10.1” WXGA TFT) enables convenient operation of the dosing system.

More information to our operating panelsWT 1-LEVEL shuttle / sliding table

Two pick-up plates operating in pendulum mode in one plane

More information to our shuttle tablesMixing head 825 PRO

MK 800 PRO precision mixing head with high-pressure water rinsing or alternative component rinsing system

More information to our mixing headsSupply Tap

Optional: Automatic SUPPLY TAP drum refilling station for low-viscosity products, e.g. isocyanate (B-component)

More information to our refilling stationsElevator

Optional: Automatic ELEVATOR drum refilling station for the A-component with pneumatic lift and agitator

More information to our refilling stationsDosing machine cabinet

The dosing machine cabinet contains the components of the dosing periphery, e.g. the dosing pumps.

More information to our dosing machine cabinetsControl cabinet

The control electronics, safety engineering and industrial PC are installed in the control cabinet.

More information to our control cabinets