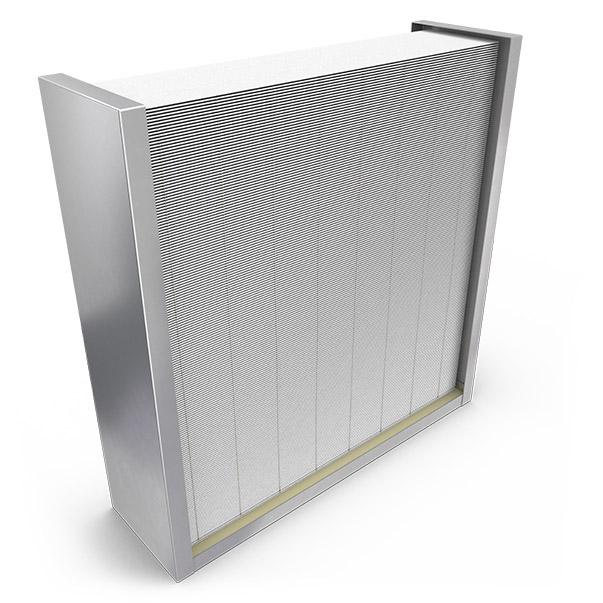

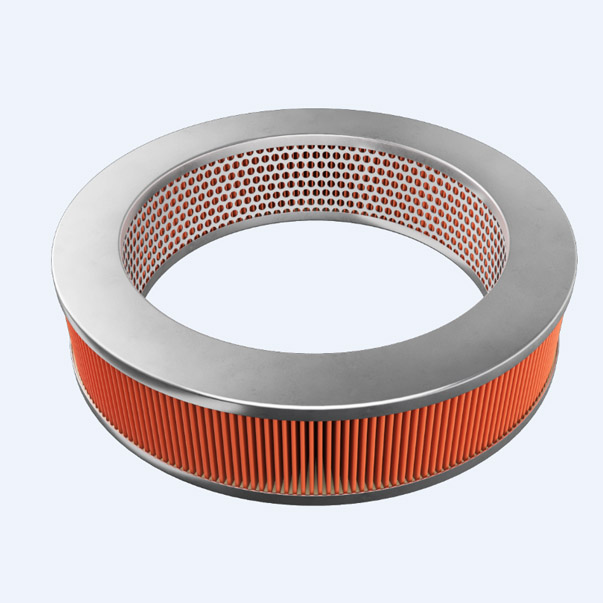

Bespoke solutions for bonding filter packs into frames or end caps

We carry out developments individually for your specific requirements

For purposes of bonding filter packs into filter frames or to the end caps, the compact, polyurethane-based 2-component adhesive sealant systems FERMADUR A-46D05-1-W or FERMADUR A-196-9-VP1 are available, each with the B-component FERMADUR-B-N.

The reference materials presented here have been used by the leading manufacturers of air filters for many years. Alternatively, whenever possible, we can also customize our material systems to meet your specific requirements.

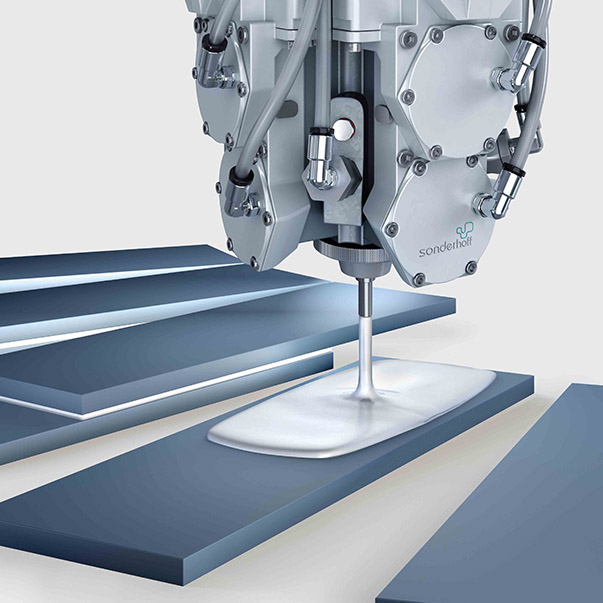

The bonding process requires precise mixing and dosing of the adhesive components, maintaining a precisely defined mixing ratio. For this purpose, we offer you our precision mixing and dosing machines, whose dosing accuracy throughout the process ensures optimal processing of the polyurethane adhesives.

Solutions for bonding filter packs into frames or end caps

The material dynamically mixed in the mixing head is applied to the filter frames or end caps, either fully automatically via the CNC-controlled MK 825 PRO precision mixing head of the DM 502 dosing system, or manually by means of the MK 50 gun of the DM 70 COMPACT dosing machine.

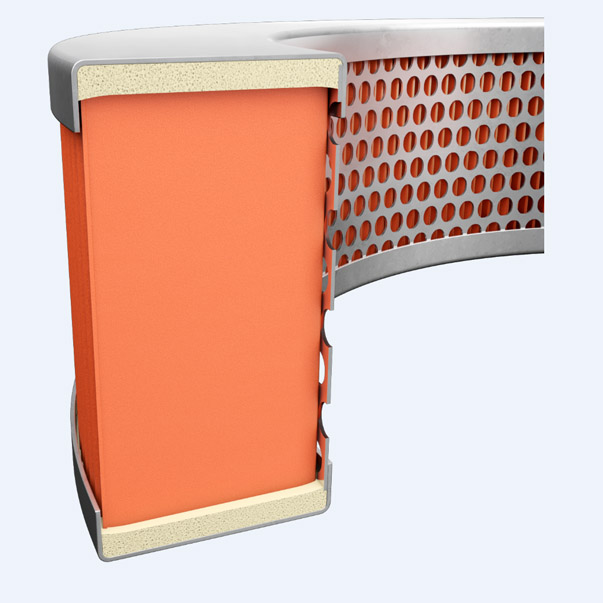

The excellent flow properties of FERMADUR adhesive sealants ensure full-surface bonding. The filter pack positioned in the filter frame is therefore optimally bonded and sealed on all sides.

The adhesive sealants are cured at room temperature, which saves the expense of the annealing oven required by other methods.

Reference material

| Air filter |

End caps and |

Frame bonding | |

| FERMADUR | A-46D05-1-W | A-196-9-VP1 | |

| FERMADUR | B-N | B-N | |

| Mixing ratio | 3 : 1 | 2.8 : 1 | |

| Pot life time | 150 sec. | 67 sec. | |

| Tack-free time | 8 min. | 3 min. | |

|

Viscosity of the A component |

5,000 mPas | 6,100 mPas | |

| Density of foam | 1.25 g/cm³ | 1.27 g/cm³ | |

| Hardness | 50 (Shore 00) | 87 (Shore A) | |

| Temperature resistance | from -40 to + 80 °C | from -40 to + 80 °C |

In addition to the reference products, we develop material systems according to your individual requirements. Influencing factors include pot life until start of foaming, curing time, and the viscosity, hardness and adhesion properties.

DM 70 COMPACT mixing and dosing system for manual bonding of filter packs into filter frames or end caps

Flexible and fully automatic – fully in line with your requirements

The DM 70 COMPACT mixing and dosing machine shown here is used to manually bond filter packs into the filter frames or to the end caps using the polyurethane-based adhesive sealant system FERMADUR A-196-9-VP1 or FERMADUR A-46D05-1-W, each of which is cured with the B component FERMADUR-B-N.

The dynamic mixing of the polymer reaction materials to be processed is carried out with the MK 50 dynamic mixing head.

This process uses a dynamic agitator in the mixing chamber of the MK 50 to homogeneously mix two material components with one another in a specific mixing ratio, the A component and the crosslinker (B component).

The dynamically mixed material is applied to the inside of the filter frame or to the end caps via the mixing head, which is designed in gun form. A full-surface bond is thus created thanks to the excellent flow properties of FERMADUR, with the filter pack optimally bonded and sealed into the frame on all sides.

The DM 70 COMPACT mixing and dosing machine is designed to enable you, the operator, to perform a wide variety of tasks easily and reliably. It is a mobile standalone system for manual operation and can be used to save space in your production facility. All machine components are mounted on a rolling chassis.

It is operated via a 7” touchscreen. This allows variable adjustment of the material feed rate and mixing ratio. The simple accessibility of the machine enables care and maintenance work to be carried out quickly and easily.