FERMADUR

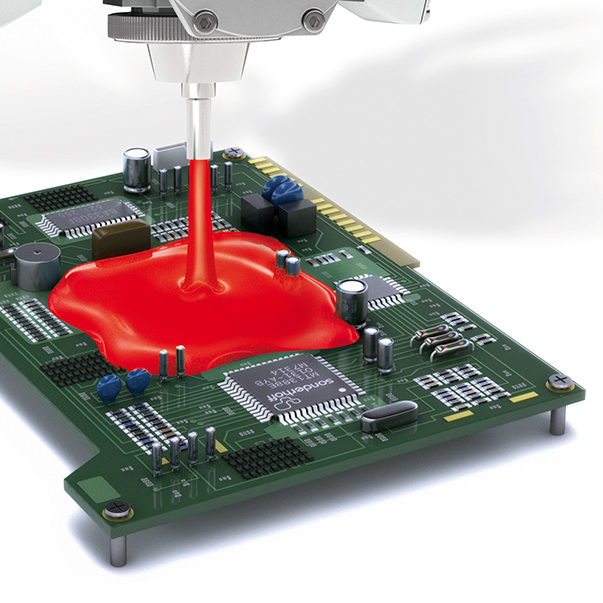

Versatile applicable for encapsulation of electronics and filters and more...

FERMADUR are the two-component polyurethane systems for the manufacture of hard- to gel-like potting compounds.

They are directly applied to the part with the aid of SONDERHOFF mixing and dosing systems using FIP (Formed-In-Place) technology and cure at room temperature.

Chemical reaction and FERMADUR properties

The systems consist of a polyurethane-based resin (A-component) and MDI isocyanate hardener (B-component), which are mixed with each other in a predetermined mixing ratio. After chemical reaction of the two material components and suitable processing a bubble-free potting compound is formed in a few minutes.

The function of the potting compound is determined by the application. It can range from surface coating to protect against environmental effects, to encapsulating electronic components or bonding components. The flowability, reactivity, degree of hardness, adhesion properties and color of the material formulations can be adjusted as required.

Henkel can draw on the variety of more than 500 application-specific formulations of the FERMADUR product family.

Your product is important to us – we will be happy to advise you!

| PHYSICAL AND CHEMICAL PROPERTIES | ||

|---|---|---|

| Property | FERMADUR | |

| Appearance | Black or grey, other colors upon request (including transparent) | |

| Hardness | Covering the entire Shore A range up to 80 Shore D, also gel-like | |

| Density | From 0.8 g/cm³ to 1.7 g/cm³ | |

| Reacton time | Adjustable from 60 s to 90 min | |

| Flame retardant | Up to UL-94 V-0 possible, even with 2 mm coating thickness | |

| Other properties |

e.g., light-fast, good thermal conductivity, can be used for rotation molding, dissipates static, hydrophobic, also available as a syntactic foam, with multilevel flow behavior, abrasion resistant, greater adhesion | |

| PROCESSING INFORMATION | ||

|---|---|---|

|

FERMADUR systems are processed using mixing and dosing machines for two components. The recommended processing temperature is 23 °C ± 5 °C at a relative humidity between 40 and 70 %. |

||

Potting systems in difficult conditions

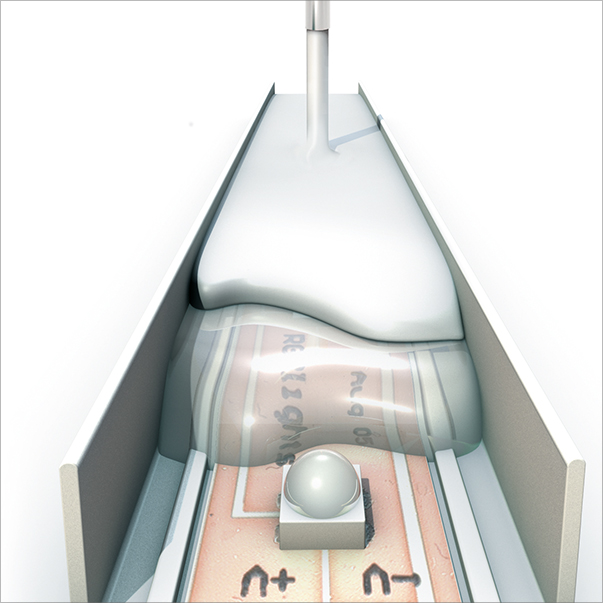

The FERMADUR systems are, with their many different characteristics, also available for use in very difficult surroundings, from outdoor or underwater uses to flame-protected applications for lighting in tunnels, or from uses requiring ATEX protection in explosion risk zones right up to optical potting, with good heat dissipation qualities for the high temperatures produced by high-power LED light technologies.

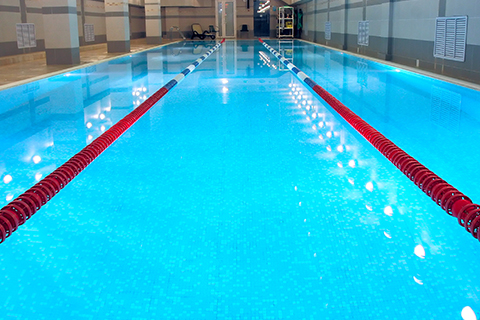

Swimming pool lighting

Depending on the complete construction, part and potting can reach impermeability classes to IP68 with FERMADUR, meaning that e. g. swimming pool lighting is possible.

Tunnel lighting

For tunnel lighting flame-retardant FERMADUR products can be created to meet UL94 V-0 testing standards.

EX protected lighting

For explosion-protected lighting elements, e.g. for emergency lighting in hazardous surroundings underground, our FERMADUR potting systems are formulated to withstand ATEX system testing in accordance with ATEX Directive 2016/34/EC.

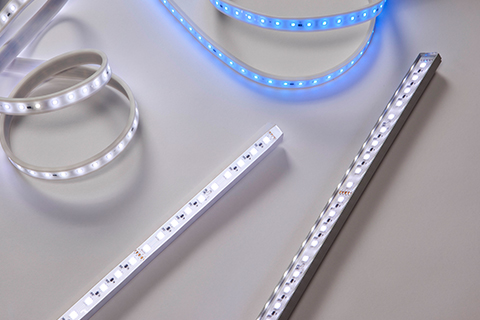

Sealing of LEDs

The transparent polyurethane-based FERMADUR potting products, e. g. for the sealing of LEDs, are protected from UV-radiation by the use of aliphatic isocyanates and are temperature-stable to 130 °C.

Broad potting spectrum covers very different requirements

The function of the FERMADUR potting system is determined by its application and can range from part protection against environmental influences through the sealing of electrical assemblies to the bonding of components such as the filter systems used in industry and the home.

Component sealing with FERMADUR potting protects parts from infiltration of damp, dust, foreign bodies, water and so on. The chemical properties of the material recipe can be varied so that the potting compound can be perfectly adapted to the task placed on it.

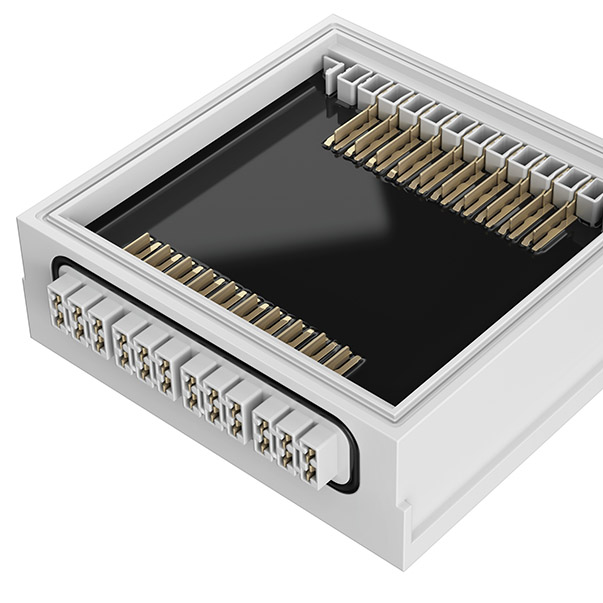

FERMADUR potting also can be used to encapsulate electronics and for interference protection and electrical insulation of cables and plugs. Potting increases the mechanical stability and dielectric strength of the electronic parts, their vibration and shock resistance.

Potting with FERMADUR products impedes detachments or the opening of crevices at the edge of the potting compound because of dramatic temperature differences or vibrations, so that damp or aggressive materials cannot penetrate the part and adversely affect its functionality or even destroy it.

According to their conditions of use, FERMADUR potting systems can be adapted widely for their ease of flow, reactivity, hardness grade and colour.

FERMADUR potting possesses a very high tear resistance and flexural strength, so that components can still be used under extreme environmental conditions.

THE FERMADUR RANGE (SELECTION)

The FERMADUR potting systems offer a wide range of properties for different applications and requirements, from potting for lighting and sensitive electronic components, through the bonding of filter packets and viewing windows in control cabinets to the coating of conveyor belts and transparent component surfaces.

| FERMADUR A-component |

Applications* | Viscosity (A) mPas |

Hardness |

Density g/cm3 |

Other properties* |

|---|---|---|---|---|---|

| A-113-5-VP1 | Potting compound for instrument and connector plugs |

2,050 | 70 Shore A | 1.07 | Flexible, levels very well, low shrinkage, low surface tension |

| A-112-VP2 | Filter gel | 200 | 22 Shore 00 | 1.02 | Very soft, gel-like, permanently sticky |

| A-134-10-VP6 | Potting compound for sensors, circuit boards, electric switches and sensor elements | 3,000 | 78 Shore A | 1.30 | Flexible standard systems for electronics in the automotive industry, listed in various OEMs, good adherence, fast curing |

| A-134-15-VP2 | Potting compound for sensors, circuit boards, electric switches and sensor elements | 7,500 | 42 Shore D | 1.40 | Hight temperature resistant, aliphatic potting compound, UV stable |

| A-125-6 | Potting compound for plugs | 1,300 | 70 Shore A | 1.12 | Flexible potting compound, low shrinkage, low surface tension, tough-elastic, fast curing |

| A-690 UL1 | Potting compound for transducers | 5,000 | 84 Shore D | 1.55 | Fast curing, tough-elastic, good dielectric properties, flame-retardant according to UL94-V0 at 1.5mm |

| A-66D05-3 | Binder natural stone | 3,300 | 45 Shore D | 1.12 | Aliphatic, UV and weather resistant, tough elastic |

| A-83D10-1-FR | Potting compound for transformers, voltage transformers, capacitors, control units |

11,000 | 85 Shore D | 1.50 | Fast curing, tough-elastic, good dielectric and flame-retardant properties |

| A-180-1-VP1 | Potting compound for light diodes | 1,100 | 70 Shore A | 1.11 | Transparent, UV stable, tough-hard, temperature stable up to +165 °C, high chemical resistance |

| A-173-3-VP1 | Potting compound for cable sheathing or molded parts for cable routing | 1,800 | 60 Shore A | 0.75 | Slightly foaming, flexible, high longitudinal water tightness achievable, very good mechanical properties |

| A-120-1-VP1 | Adhesive for panes in enclosures | 213,000 | 30 Shore D | 1.25 | Tough-hard, good adherence on various substrates, high mechanical stability, can be used as a glue, highly thixotropic |

| A-25D45-01-R | Rotation molding compound | 50,000 | 45 Shore D | 0.40 | Hard, foamed potting, thixotropic |

| A-80DC8-1-CON | Rotation molding compound for ferrules | 191,000 | 78 Shore D | 1.25 | Non-drip, high stability and chemical resistances, static dissipative coating |

| A-196-4-F | Potting compound for filter end caps and adhesive for filter cartridges | 1,000 | 64 Shore D | 1.16 | Tough-hard, good adherence to various substrates, microbial inert |

* The description of the possible fields of use of our products as well as the technical data and values only have a general character and do not mean that a certain product can be used under all conditions in the respective field of use. In this respect, the stated field of use is not a binding specification or usage provision. Due to the great number of environment variables and their influences (e.g. temperature, test specimens, size, interaction with substrates, influence of machines, or the like) you as our customer must check whether the product is suitable for your specific field of use. We will be pleased to assist and advise you in this respect.

Good reasons for using FERMADUR

- … is most suitable for sealing industrial components.

- ... after curing, it develops a cross-linked structure which is extremely resistant to environmental effects, such as humidity, dust, mechanical impacts and temperature.

- ... reacts at room temperature in > 5 minutes. A furnace can significantly shorten the reaction time, but it is not always necessary.

- ... achieves particularly good adhesion to the parts’ surface due to the chemical reaction of the two components on the carrier material.

- ... offers an exceptional long-term behavior and is distinguished by high heat resistance and an extremely low expansion coefficient.

- ... the viscosity can be formulated from a thin fluid to a thick paste.

- ... is also available in transparent and light-fast formulations.

- ... has low shrinkage and low surface tension, good dielectric properties and also very high impact strength.

- ... is processed using a mixing and dosing machine for two components and can be adapted flexibly and quickly to other parts for potting application at any time.

- ... even the processing of small product series becomes profitable with it.