Performance & Maintenance Hub

See what matters - for actionable insights

For maximum efficiency and availability of your machines

With the IoT Performance & Maintenance Hub, you lay the foundation for smart, data-driven optimization of your production – reliable and future-proof.

By embedding over 30 years of machine and process expertise, decisions are no longer based on gut feeling – but on data: efficient, forward-looking, and targeted.

The result: e.g. reduced downtime leading to significantly higher Overall Equipment Effectiveness (OEE).

Performance

Maintaining visibility of relevant performance and maintenance metrics is a challenge in complex production environments with many interconnected components.

Our performance dashboards provide targeted support:

- They intelligently aggregate and visualize performance data, generate automated evaluations, and highlight areas requiring action.

- They enable continuous monitoring and optimization of machine and system performance – optionally in real time.

- By analyzing recorded process, alarm, and machine data, efficiency losses, downtimes, and deviations can be identified early and addressed in a targeted manner.

Maintenance

Modern production processes require numerous parameters to align, with every machine component contributing to a consistently uniform result.

For maintenance, it is therefore essential to detect deviations early in order to intervene accordingly.

Our maintenance dashboards provide targeted support:

- Display actual wear-related process and machine data to enable needs-based maintenance.

- This reduces unnecessary downtime, prevents unplanned failures, and ensures long-term system availability.

Performance & Maintenance Hub

Our dashboards answer your questions!

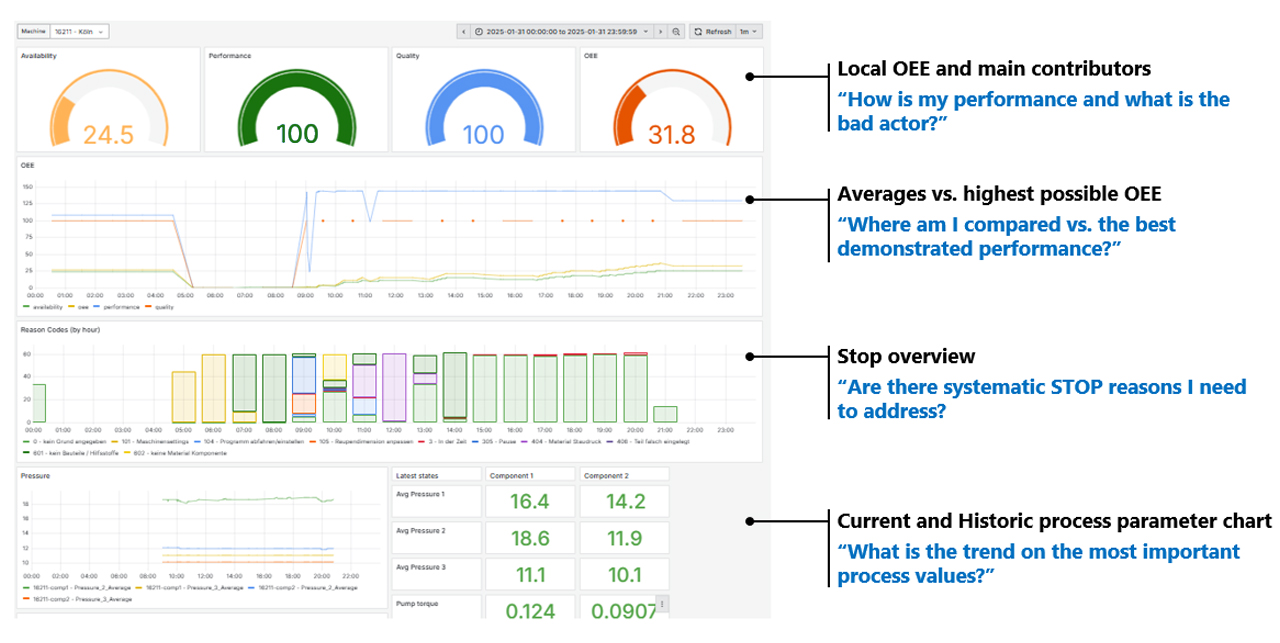

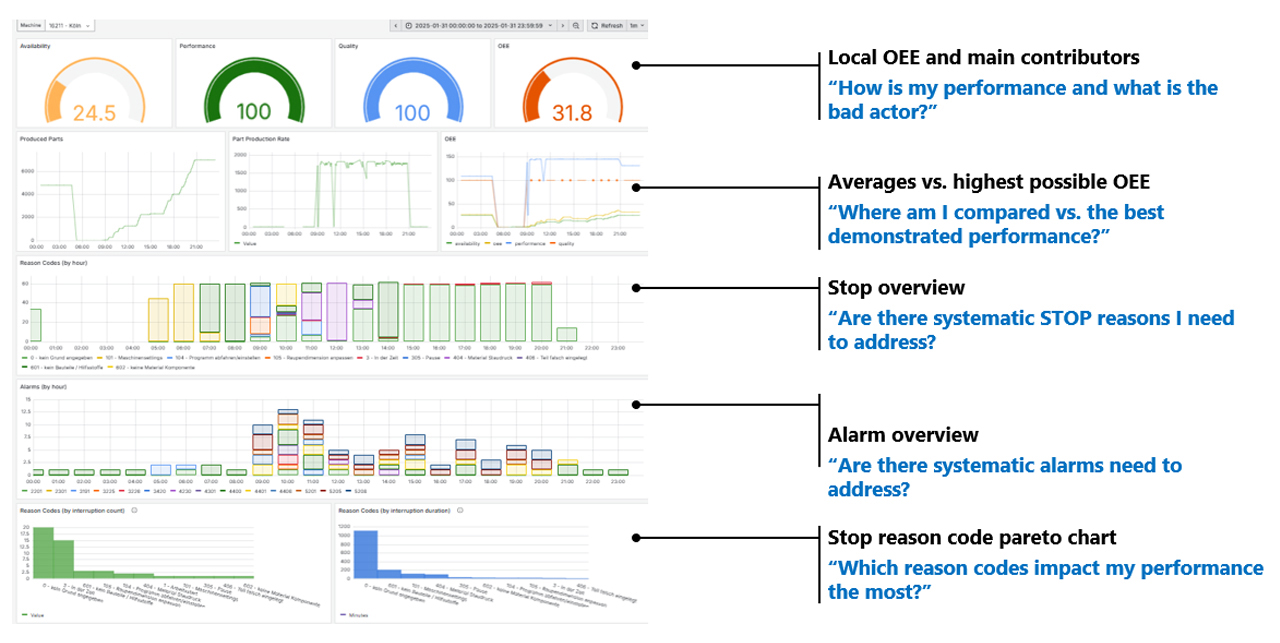

- "How is my performance and what is the bad actor?”

Local OEE and main contributors - “Where am I compared vs. the best demonstrated performance?”

Averages vs. highest possible OEE - “Are there systematic STOP reasons I need to address?”

Stop overview - “Are there systematic alarms need to address?”

Alarm overview - “What is the trend on the most important process values?”

Current and Historic process parameter chart - “What are the differences in performance and why?”

Global machine performance comparison - “What is really the situation?”

Process overview with “look-and-feel” from machine

- “Which alarm occurred and what was the process at that time?”

Historic Machine Alarm - “How did the process change over time?”

Self configurable process trends - “Who do process parameters and production correlate?”

Fully adjustable deep-dive telemetry - “How did the material batch impact production?”

Operation status, material batches and alarm pareto - “How does dosing and pump torque correlate?”

Review individual components - “Was switch DVS off the right decision?”

Review individual function

Performance dashboards

Local view

Performance dashboards

Single-Machine OEE performance

Performance dashboards

Multi-Machine OEE performance comparison

Performance dashboards

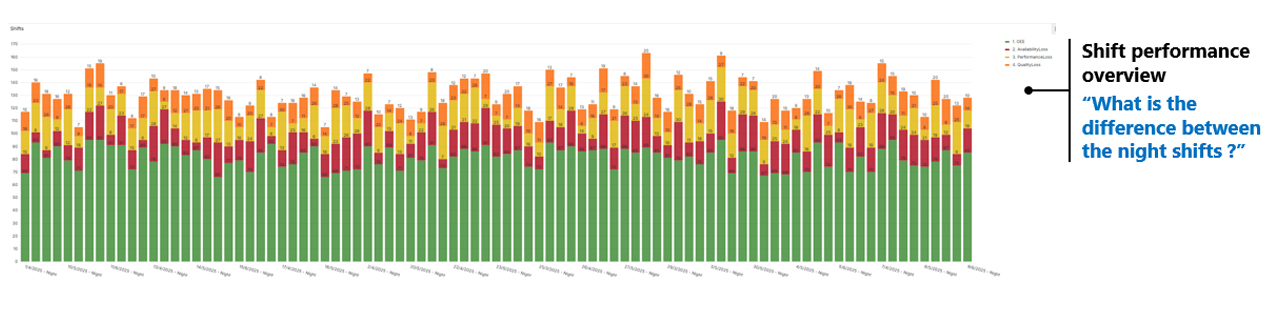

Shift performance comparison

Performance & Maintenance Hub

See what matters - for actionable insights

More than 300 data points provide precise insights – and can be freely combined to match your specific needs.

MACHINE

- Actual type number

- Alarms

- Availability[%]

- Best_demonstrated_cycletime[ms]

- Event

- Interruption time planned total[s]

- Interruption time[ms]

- Interruption_time_total[s]

- Microstop time[ms]

- Microstop_time_total[s]

- Microstops count[-]

- Part cycletime[ms]

- Performance[%]

- Possible_parts_per_cycle

- Possible_parts_total

- Produced parts not OK[-]

- Produced parts[-]

- Production_time_running[s]

- Quality[%]

- Reason code

- Tolerance_time[ms]

- Tolerance_time_total[s]

- User Logs

MIXING HEAD

- Active components list

- Ambient humidity / temperature

- CS dosing

- DVS - close delay

- DVS - delay set for dosing valves open

- DVS - distance traveled

- DVS - gap limiter position

- DVS - last support sealing height

- DVS - movement duration

- DVS - open delay / position

- DVS - time until DVS close/open starts

- Dosing quantity

- Dosing time

- Inactive time

- Mixer speed

- Mixer torque

- Mixing chamber temperature

- Part temperature

- Password level

- Recipe number

- Total piece counter

- fixture in station

- machine serial number

COMPONENT

- Active componente

- Batch info

- Correction factor pump

- Density

- Dosing needle - closed position

- Dosing needle - distance traveled

- Dosing needle - movement duration

- Dosing needle - open position

- Dosing needle - time until dosing needle

- Dosing quantity

- Flow rate

- Material info

- Max. pressure dosing unit

- Max. pressure after pump

- Max. pressure before pump

- Med. pressure after pump

- Med. pressure before pump

- Med. pressure dosing unit

- Min. pressure after pump

- Min. pressure before pump

- Nucleation value

- Pump rotation speed

- Pump torque