Sealing of electric motors

Whenever something turns or moves at the touch of a button, whether in private households, in industry, or in other areas, there are probably electric motors at work. Though often hidden, quiet and inconspicuous, they often do their work for years on end without us giving it much thought. It has become impossible to imagine our modern world without them, however. They can be found in household tools and washing machines, kitchen and garden appliances, and are used for window blinds, awnings, garage doors and many other applications.

Electric motors are used to convert electrical energy into mechanical energy, which is then used to perform mechanical work. Electric motors in industry have very different requirements – electrical drive systems are therefore used in different types of motors, e.g. for conveyor belts, cranes, construction elevators, industrial robots, tool drives, fans, and pumps. The terminal box is responsible for the electricity supply of the electric motor. The power connection here needs to establish and maintain a permanently safe electrical connection.

No moisture, dirt or other foreign bodies can therefore be permitted to enter the terminal box. The terminal box must be sealed to be dust-proof and watertight in compliance with DIN 42925.

For this purpose, we offer our 2-component FERMAPOR K31 polyurethane-based sealing foams. The applied foam gasket provides excellent sealing in the installed state due to compression of the foam structure.

Are you looking for a solution for sealing terminal boxes for the electrical supply of electric motors, consisting of a material system, dosing system and process automation from a single source?

We will provide you with a perfectly coordinated sealing solution, consisting of a sealing foam that satisfies your requirements and a dosing system for high-precision, fully automatic material application, controlled by contour robots.

Do you require a flexible automation system that can be variably adapted to your production conditions?

The modular design of our mixing and dosing systems allows flexible use, with excellent integration into existing production concepts.

With its high dispensing accuracy and systematic process monitoring our efficient mixing and dosing system is very easy and intuitive to operate.

Tailored material systems for maximum product safety

We carry out developments individually for your specific requirements

The terminal box for the electrical supply of electric motors is sealed against the penetration of moisture, dirt and other foreign bodies with our 2-component FERMAPOR K31 polyurethane foams.

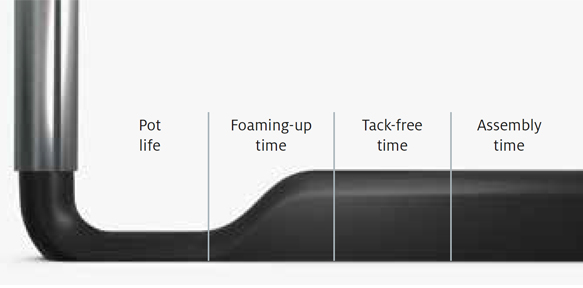

The reference material presented has been tried and tested for many years, and is used by leading manufacturers. Alternatively, we can also optimally adapt our FERMAPOR K31 2-component sealing foams to meet your requirements. Influencing factors include pot life until start of foaming, curing time, and the viscosity, hardness and adhesion properties. Thanks to the mixed-cell foam structure, the closing forces when installing the foam gasket are low.

FERMAPOR K31 FAST-CURE foams react very quickly, allowing cost savings due to short curing times. Intermediate storage of components to allow curing of the foam gaskets is unnecessary.

The different reaction phases of the sealing foam in the chronological sequence

Reference material

| FERMAPOR K31-A-9230-2-VP | |||

| FERMAPOR K31-B-4 | |||

|

Mixing ratio |

4 : 1 | ||

|

Pot life time |

53 sec. | ||

|

Tack-free time |

8 min. | ||

|

Viscosity of the A component |

50,000 mPas | ||

|

Density |

0.3 g/cm³ | ||

|

Hardness (Shore 00) |

60 | ||

|

Temperature resistance |

from -40 to + 80 °C | ||

|

Pretreatment |

Adheres well to powder-coated surfaces. |

In addition to the reference products, we develop material systems according to your individual requirements. Influencing factors include pot life until start of foaming, curing time, and the viscosity, hardness and adhesion properties.

Frequent opening and re-closing of the terminal box for maintenance purposes, while maintaining a consistent sealing effect

During final assembly of the terminal box, the foam gasket applied is evenly compressed over the entire housing contour, resulting in a high degree of tightness once installed, in accordance with IP protection classes or NEMA.

Due to its excellent resetting ability of the foam sealing behavior, the mixed- cell foam structure of the polyurethane seal can still be compressed even after years (tested according to DIN EN ISO 1856). This allows frequent opening and re-closing of the terminal box for maintenance purposes, while maintaining a consistent sealing effect of the foam gasket.

The video shows the polyurethane foam seal FERMAPOR K31 in cross section - first in the uncompressed state, then 50 % compressed, so that the sealing function of the seal is given.

The video shows the polyurethane foam seal FERMAPOR K31 in a cross section in a groove - first in the uncompressed state, then about 50% compressed, so that the sealing function of the seal is given and the component is tight.

The unpressed polyurethane foam gasket before installation.

Cross-section of a polyurethane foam bead in the groove and pressed to approx. 50 %

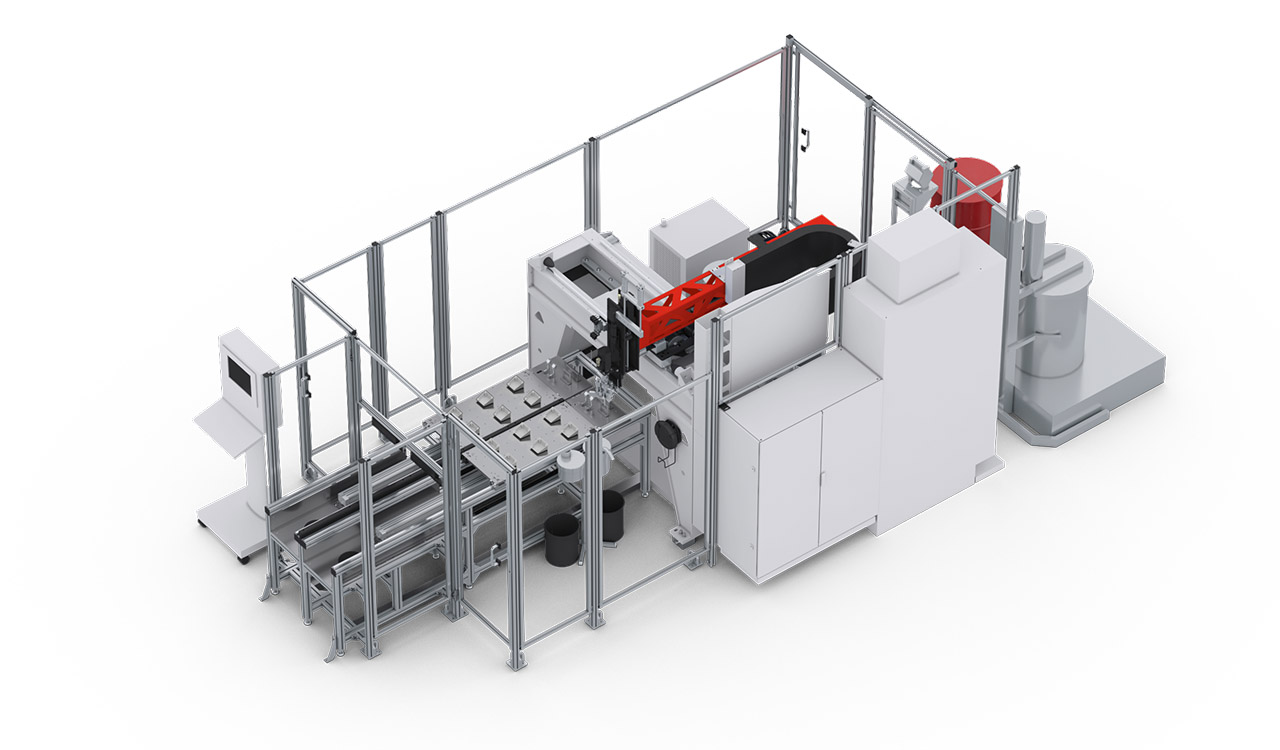

Mixing and dosing system with 3-axis linear robot and a shuttle table for picking up parts

Flexible and fully automatic – fully in line with your requirements

As process experts, we support you with tailored advice for the automation of your manufacturing processes. To achieve this, we offer numerous configuration and equipment options for semi- automatic or fully automatic production systems.

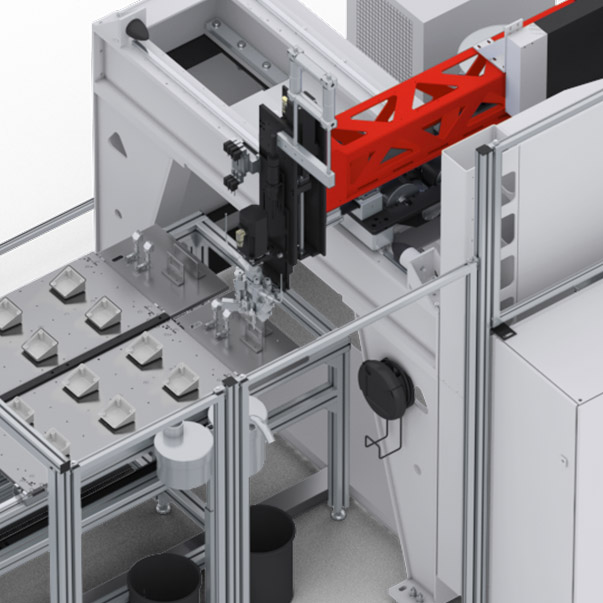

The reference configuration shown here for sealing the housings of terminal boxes for the electrical supply of electric motors consists of the DM 502 mixing and dosing system with LR-HE plus 3-axis linear robot and WT 1-LEVEL shuttle table for picking up parts. The two pick-up plates working in shuttle mode enable the workpieces to be picked up and alternately processed in a single plane. This makes it possible to guarantee continuous operation.

The electric motor terminal box housing to be sealed is positioned and fixed in place on the shuttle table either by a machine operator, who can also check the parts for quality, or by a Pick & Place Robot. In the latter case, an optionally installed camera or sensor system could carry out the quality control of the parts.

For small to larger terminal boxes, thixotropic sealing material is dispensed into the groove of the three-dimensional housings or lids via the CNC-controlled MK 825 PRO precision mixing head. The dosing process must be very precise, especially when dealing with very narrow grooves. After the dosing cycle, the coupling point of the room-temperature-curing foam gasket closes seamlessly and is almost invisible.

Even with short cycle times and high unit numbers, the material application process using the FIPFG method is carried out with high dosing precision and repeat accuracy. As a result, you achieve foam gaskets of uniformly high quality.

In addition, our fail-safe mixing and dosing system can be operated easily and intuitively without the need for extensive training.

Thanks to the automatic logging of dosing program data, all process data can be traced and evaluated by the machine operator via the CONTROL 2 operating panel while production is running.

In all solutions, our main focus is on extremely reliable plant engineering, minimized maintenance times and consistent dosing quality.

CONTROL 2

WT 1-LEVEL shuttle / sliding table

MP 2 Mobile panel

Mixing head 825 PRO

Dosing machine cabinet

Control cabinet

Supply Tap

Elevator

CONTROL 2

WT 1-LEVEL shuttle / sliding table

MP 2 Mobile panel

Mixing head 825 PRO

Dosing machine cabinet

Control cabinet

Supply Tap

Elevator

CONTROL 2

Optionally available: CONTROL touchscreen operating panel (21.5“) for operating the dosing system

More information to our operating panelsWT 1-LEVEL shuttle / sliding table

Two pick-up plates operating in pendulum mode in one plane

More information to our shuttle tablesMP 2 Mobile panel

The multifunctional MP 2 mobile panel (10.1” WXGA TFT) enables convenient operation of the dosing system.

More information to our operating panelsMixing head 825 PRO

MK 800 PRO precision mixing head with high-pressure water rinsing or alternative component rinsing system

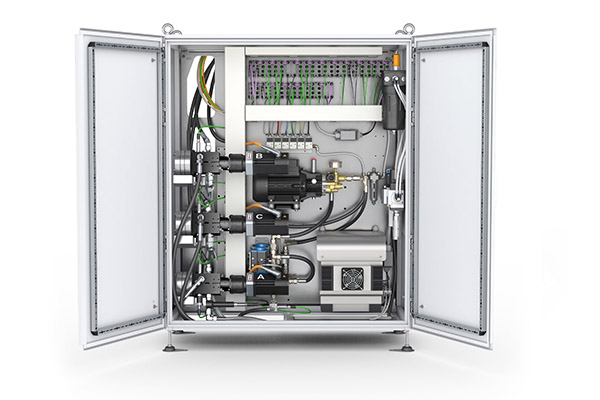

More information to our mixing headsDosing machine cabinet

The dosing machine cabinet contains the components of the dosing periphery, e.g. the dosing pumps.

More information to our dosing machine cabinetsControl cabinet

The control electronics, safety engineering and industrial PC are installed in the control cabinet.

More information to our control cabinetsSupply Tap

Optional: Automatic SUPPLY TAP drum refilling station for low-viscosity products, e.g. isocyanate (B-component)

More information to our refilling stationsElevator

Optional: Automatic ELEVATOR drum refilling station for the A-component with pneumatic lift and agitator

More information to our refilling stations